Flexible noiseless self-sinking type non-slip floor

A self-sinking, silent technology, used in coatings, building elements, layered products, etc., can solve the problems of dust dispersion and rough ground surface, and achieve the effect of easy operation, simple installation and unique concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

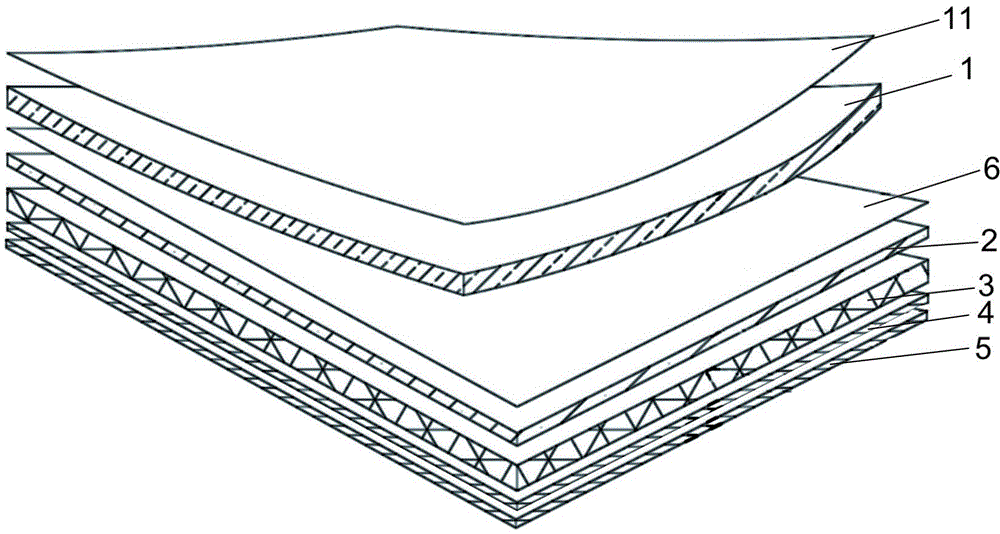

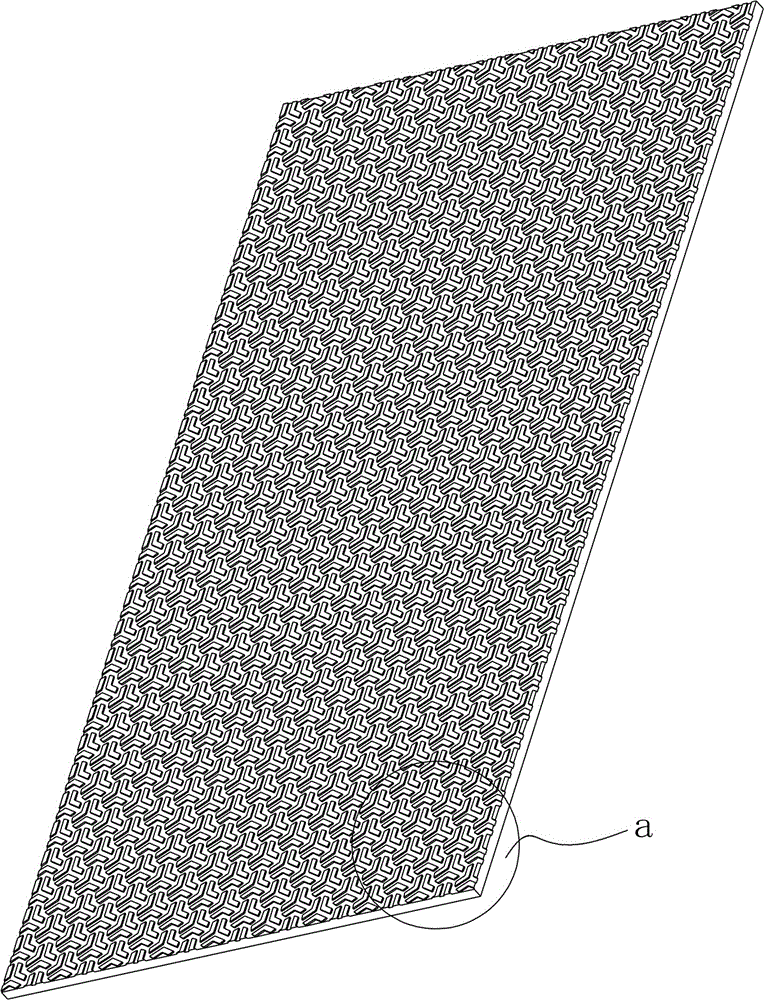

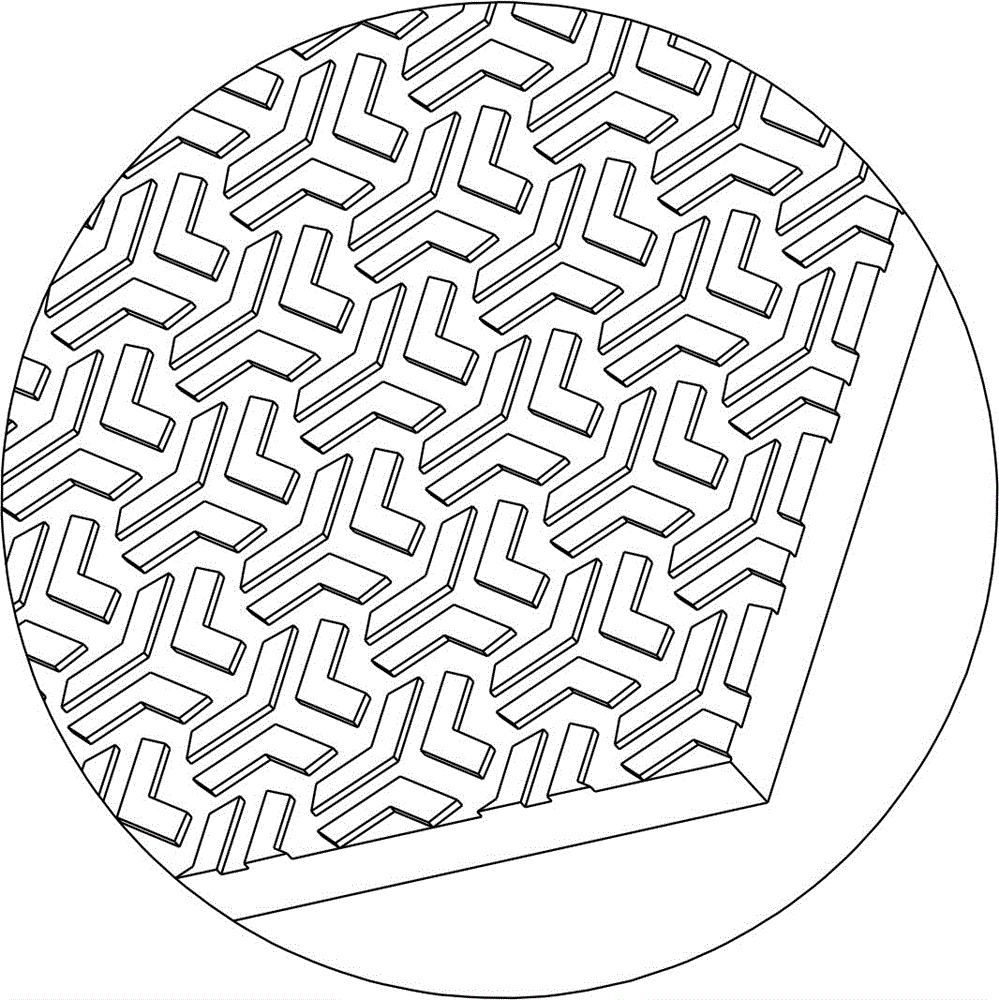

[0032] see Figure 1-7 , this embodiment includes a composite surface layer 1, an anti-slip film layer 5, and the anti-slip film layer 5 is provided with anti-slip embossed lines, concave lines or a combination of the two. Do not close the shading.

[0033] In this embodiment case, as a preference, it includes a surface layer 1, a first stable layer 2, a glass fiber grid layer 3, a second stable layer 4, and an anti-slip film layer 5 that are sequentially compounded, and the anti-slip film layer 5 is provided with anti-slip embossed lines , grooves or a combination of the two. The shading is an unclosed shading with an opening. The unclosed shading can make the floor sink on the ground and generate a large friction coefficient with the ground. It can prevent air from remaining in one place and produce local stress during compression. The non-closed shading is provided with an air channel passing through the shading of the anti-slip film layer 5, and the air channel can be fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com