A kind of antistatic optical fiber and its preparation method

A technology of antistatic and antistatic agent, which is applied in the direction of cladding optical fiber, optical waveguide light guide, fiber mechanical structure, etc., can solve the problem that the static electricity of optical fiber cannot be fundamentally eliminated, and achieve the effect of reducing electrostatic effect and lowering resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] On the other hand, the embodiment of the present invention provides a method for preparing the above-mentioned antistatic optical fiber, which includes: mixing the coating used to prepare the coating with the antistatic agent according to the mass ratio of the coating and the antistatic agent to obtain a mixed coating, and then The mixed paint is coated on the outer surface of the optical fiber, and after drawing and curing, an antistatic optical fiber is obtained.

[0044] Among them, in the above preparation process, the optical fiber in "coating the mixed coating on the outer surface of the optical fiber, after drawing and curing" refers to the optical fiber that has been coated with an inner layer or optional other coatings. For example, when the outermost layer is the outer layer of a resin coating, the optical fiber here refers to an optical fiber that has been coated with an inner layer. When the outermost layer is an ink layer, the optical fiber here refers to an o...

Embodiment 1

[0067] This embodiment provides an antistatic optical fiber with an antistatic agent in the outer coating, and the preparation method is as follows:

[0068] Add the antistatic agent: monododecyl phosphate to the coating used to prepare the outer coating, and stir it evenly to obtain the mixed coating. The mixed coating is passed through the fiber drawing tower with a certain diameter, speed and energy on the substrate Optical fiber: Coating and drawing and curing the A fiber to form an antistatic optical fiber with an antistatic agent in the outer coating. Wherein, the mass of monododecyl phosphate is 1.1% of the mass of the outer coating.

[0069] A digital insulation resistance tester was used to test the resistivity of the antistatic fiber and the base fiber, and the results are as follows: the resistivity of the antistatic fiber in this embodiment is 4.2×10 6 Ω·cm; the resistivity of the base fiber of this embodiment is 9.2×10 8 Ω·cm. It can be seen that, by adding an antista...

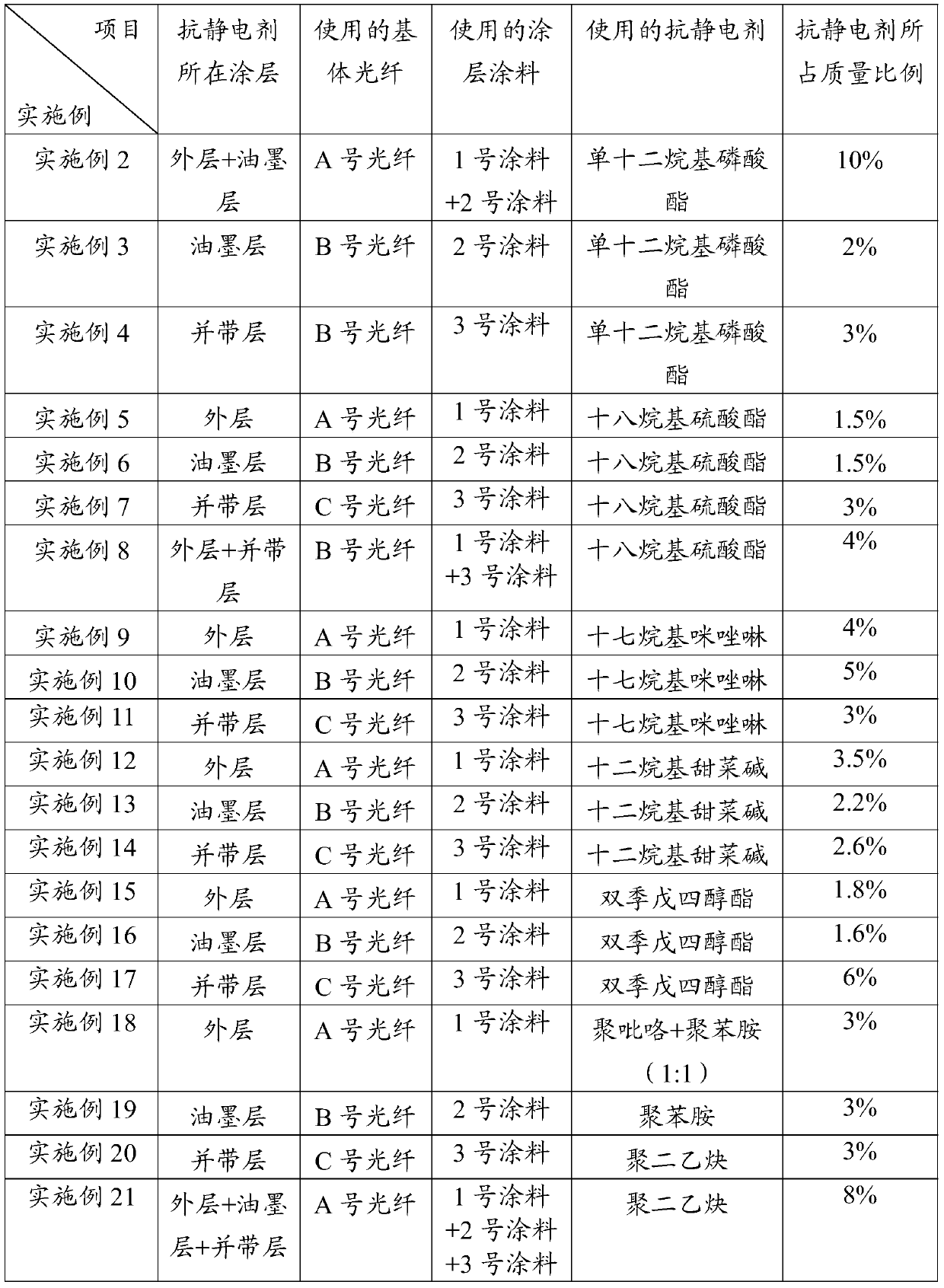

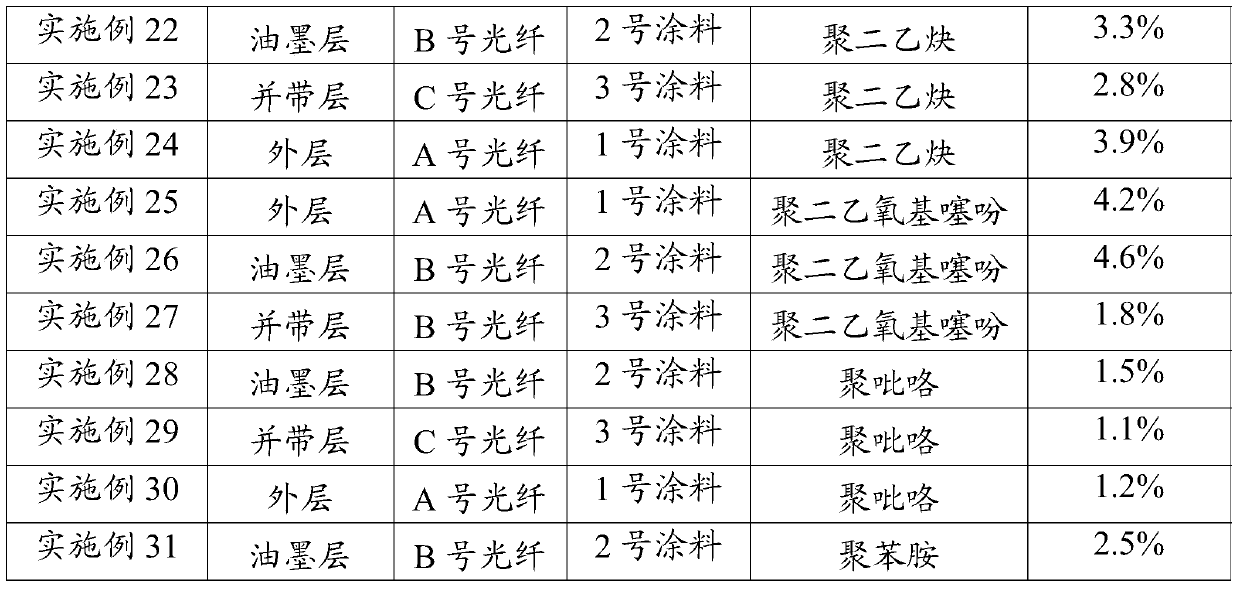

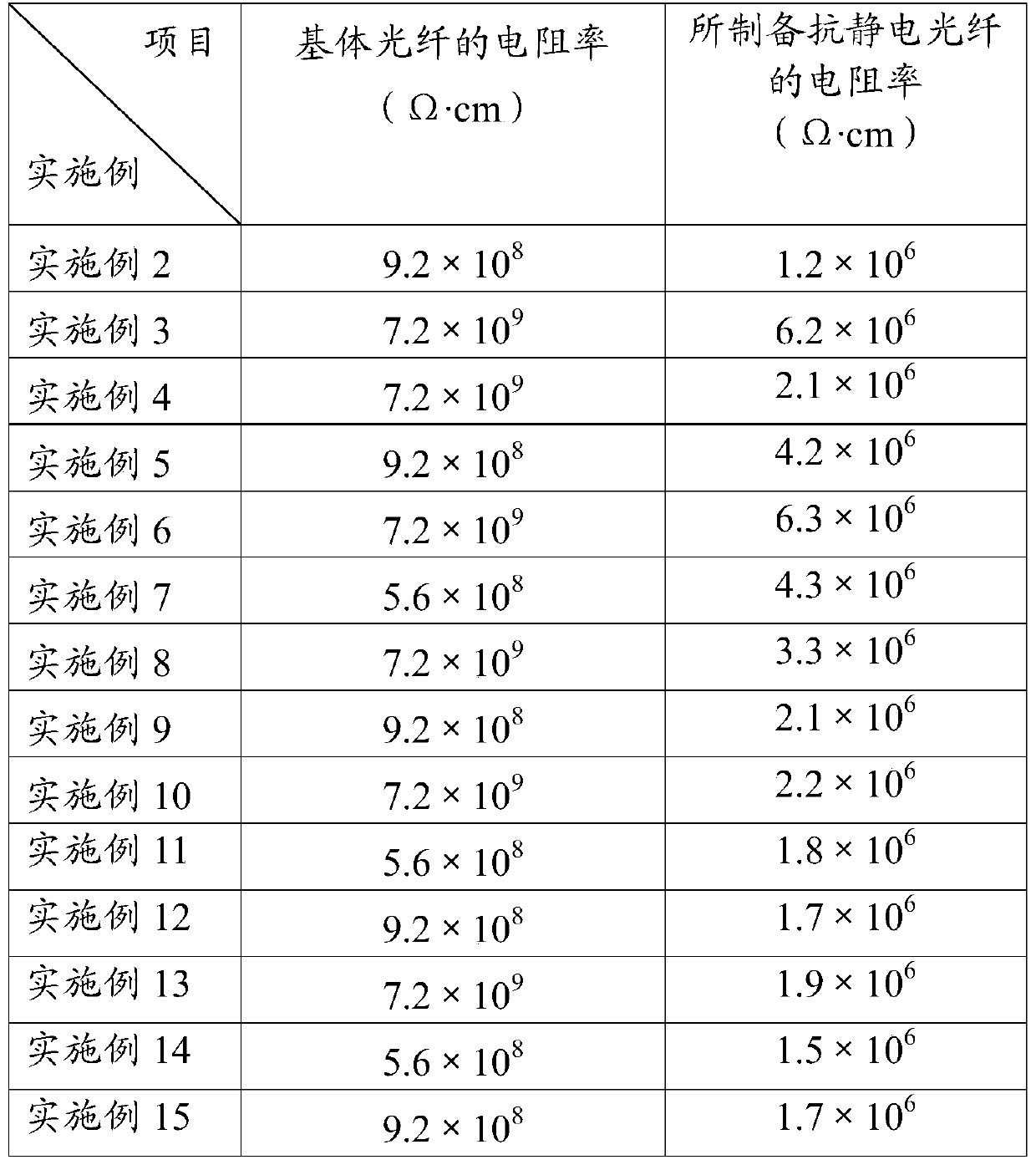

Embodiment 2— Embodiment 31

[0071] The methods adopted in the above embodiments are the same as those in the first embodiment. The difference lies in the coating where the antistatic agent is located, the coating used for the coating containing the antistatic agent, the antistatic agent used, the mass percentage of the antistatic agent in the coating, and the base fiber used. For the specific differences between Example 2 and Example 31, see Table 1. A digital insulation resistance tester was used to test the resistivity of the antistatic optical fiber and the base optical fiber prepared in Example 2 to Example 31, and the test results are shown in Table 2.

[0072] Table 1

[0073]

[0074]

[0075] Table 2

[0076]

[0077]

[0078] It can be seen from Table 2 that by adding an antistatic agent to the coating in the embodiment of the present invention, the resistivity of the optical fiber can be significantly reduced, and the antistatic performance of the optical fiber can be effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com