Batch process weak fault model control limit establishment method and weak fault monitoring method

A technology for model control and establishment of methods, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., and can solve problems such as weak fault monitoring, large fluctuations in initial conditions, and complex algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

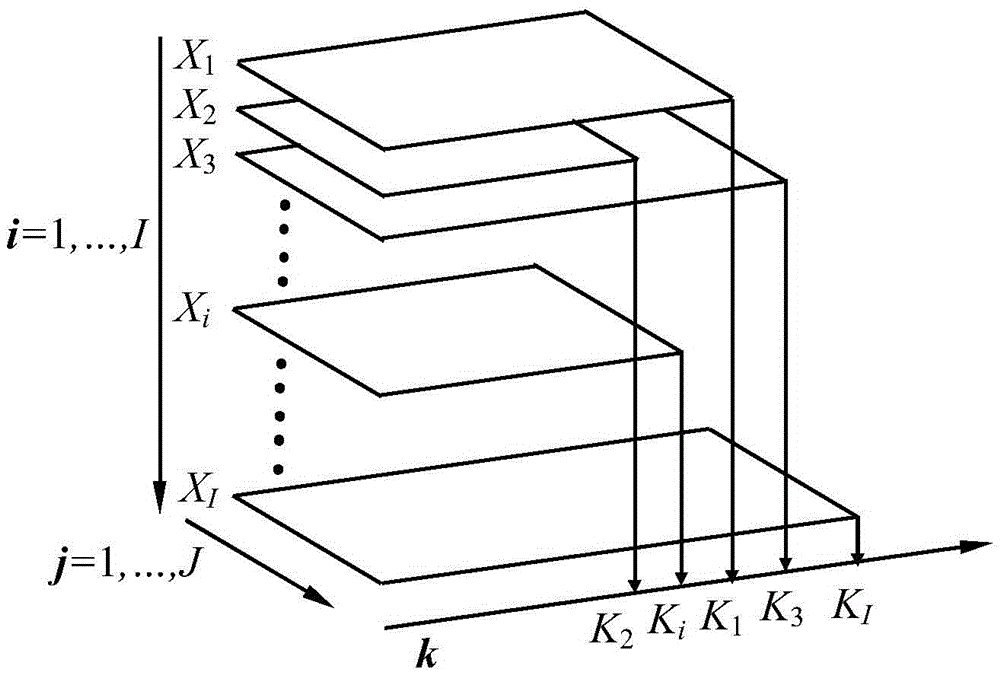

[0068] Such as figure 1 As shown, the present invention provides a method for establishing a weak fault model occurring in the monitoring process, comprising the steps of:

[0069] Step 1. Collect data under normal working conditions.

[0070] Under normal working conditions, collect I batches of normal operation data i=1,...,I,K i Indicates the number of sampling points of the i-th batch, J is the number of variables collected, as shown in the attached figure 1 shown. That is, each variable in the i-th batch collects K i sampling points. If the number of sampling points in the first four batches is 400, 420, 420, 460 respectively, then K 1 =400, K 2 =420,K 3 =420,K 4 =460.

[0071] Step 2: Denoise each batch of data by variables using Donoho's threshold denoising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com