An intelligent control system and control method for loading granular materials

An intelligent control system and granular material technology, applied in the direction of control/regulation system, liquid level control, non-electric variable control, etc., can solve the problems of dust pollution, low work efficiency, personal hazards of staff, etc., to prevent overload, Ease of assembly and prevention of misloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

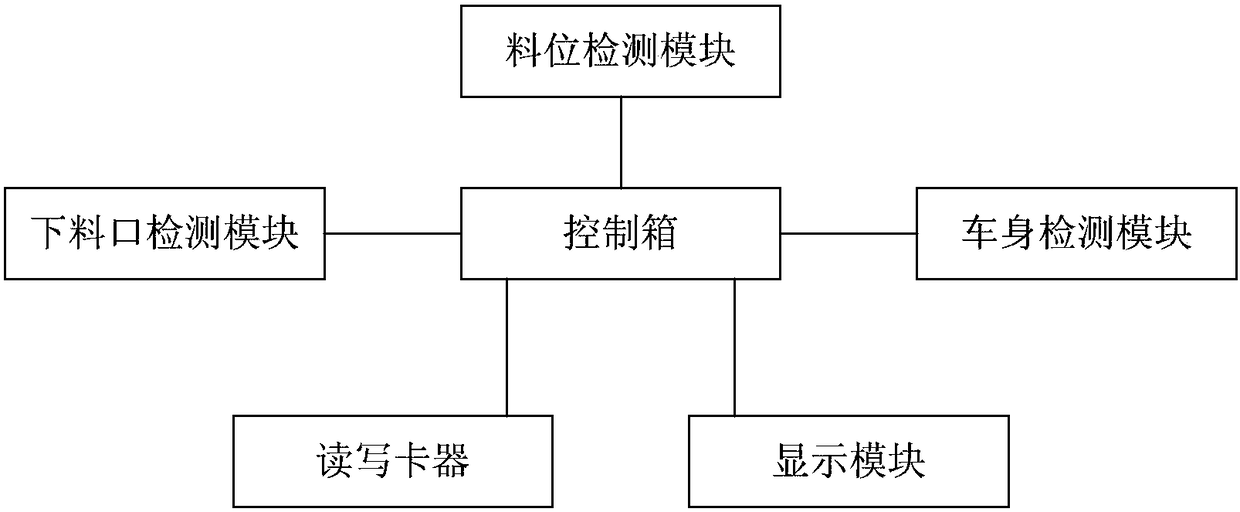

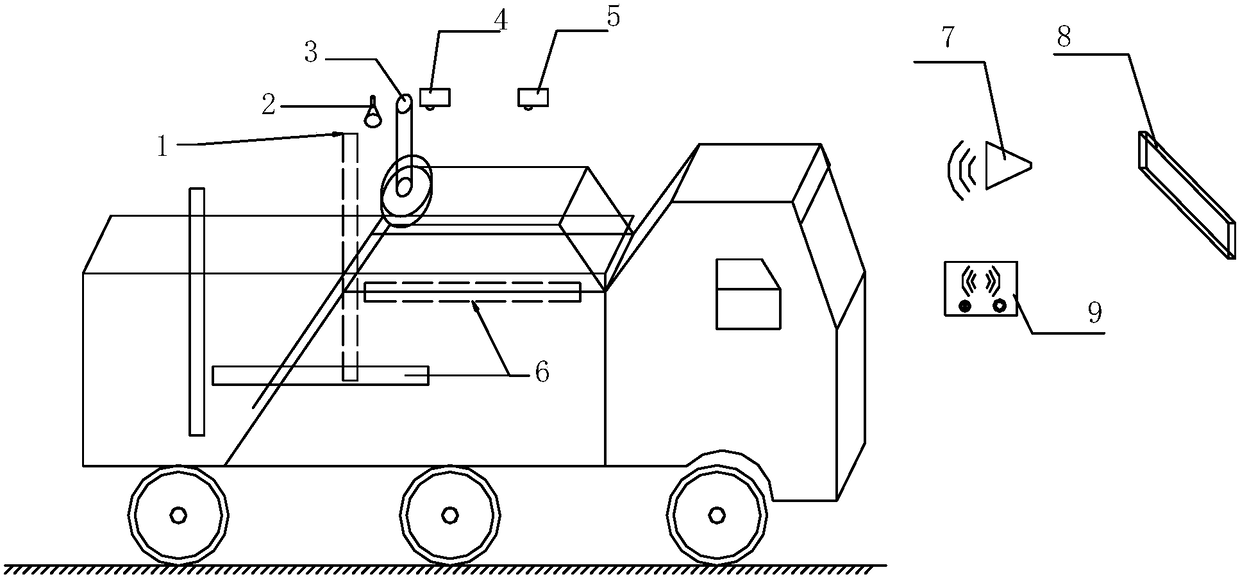

[0071] see figure 1 and figure 2 , an intelligent control system for loading granular materials, including:

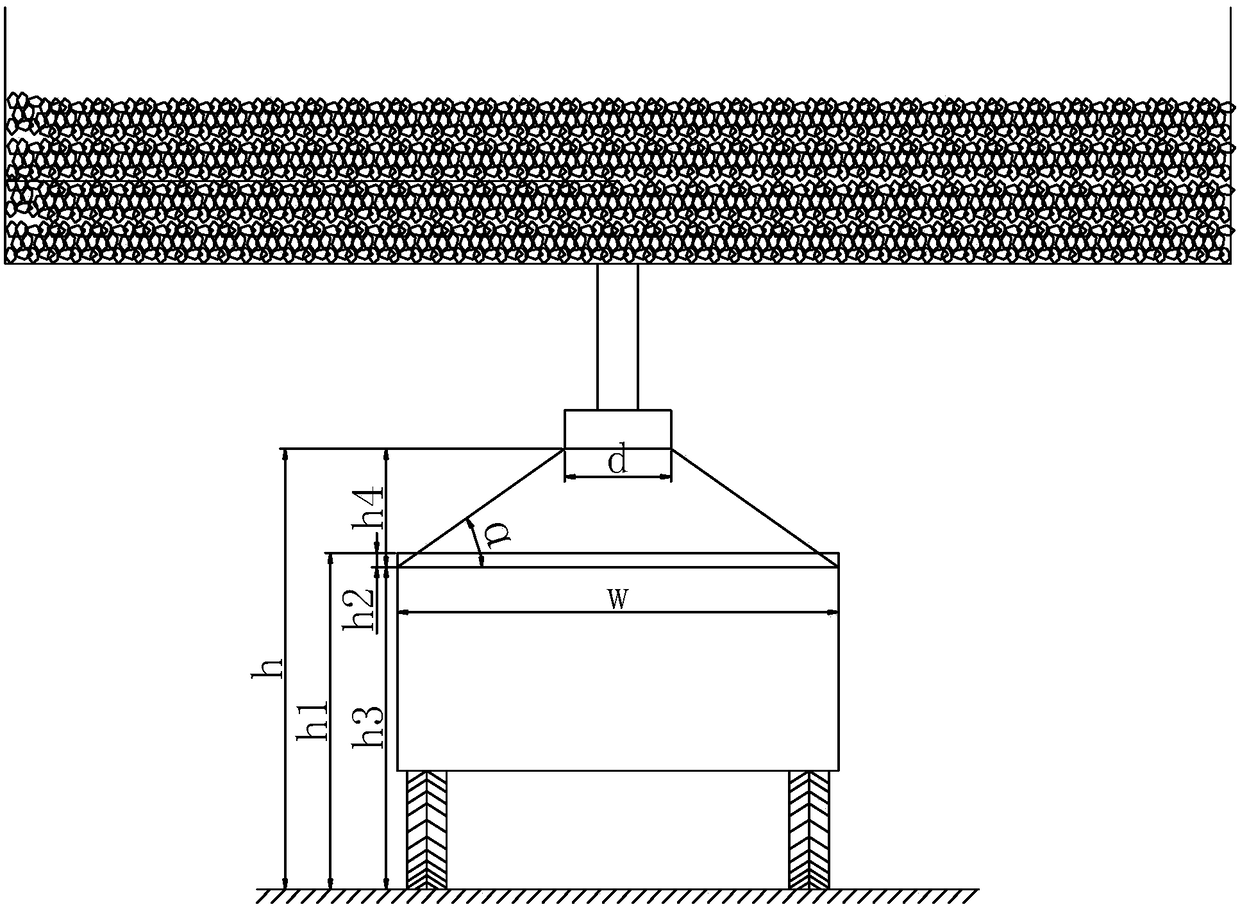

[0072] A vehicle body detection module for collecting vehicle body information; the vehicle body detection module includes a first sensor 6 for detecting the rear distance, a second sensor 1 for detecting the height of the compartment, and a third sensor for detecting the bottom height of the compartment ; the third sensor is figure 2 The second laser ranging sensor 5 in the vehicle; the distance at the rear of the vehicle refers to the shortest distance from the feed opening to the rear of the vehicle body. The rear of the vehicle body is generally a plane, and here refers to the vertical distance from a point to a surface. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com