Improved waveguide probe transition based structure for performing modular packaging for chip

A modular, probe technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of chip energy transmission limitation, poor matching of module input and output ports, etc., to achieve good return loss, The effect of low insertion loss and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

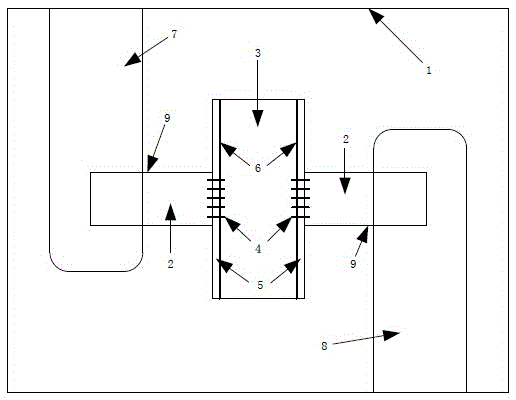

[0026] Such as Figure 1~3 As shown, the chip is modularly packaged based on the improved waveguide probe transition structure, including a metal cavity 1; the metal cavity is provided with more than one waveguide cavity, and more than one transition probe 2; the transition One end of the probe is located in the waveguide cavity, and the other end of the transition probe is provided with a chip 3 that needs to be packaged; the chip is connected to the transition probe through a bonding gold wire 4, and a conductive glue is provided at the junction 5 or / and metal boss 6.

[0027] Among them, the metal cavity can be gold-plated for good grounding; the probe adopts a multi-level high and low impedance matching section structure to achieve a good match between the chip and the module port; The section where the chip connects with the transition probe is edge-sealed with conductive glue, which significantly reduces the loss caused by the modular package. As a preference, the chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com