Novel high-efficiency filtering water treatment membrane stack

A water treatment membrane and high-efficiency filtration technology, applied in the direction of osmosis/dialysis water/sewage treatment, membrane, membrane technology, etc., can solve the problems of aggravating membrane pollution, shortening the service life of membrane stacks, and reducing water treatment efficiency. The effect of improving water treatment efficiency, increasing contact area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

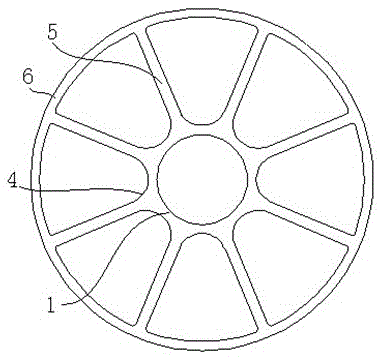

[0031] As a preference, such as figure 2 As shown, the guide vane is a straight support bar 5 whose width is equivalent to the ring width of the installation ring. The outermost end of the ring is also connected with a supporting ring 6 which is annular and concentric with the mounting ring. In this way, the diaphragm is fully supported and isolated.

Embodiment 2

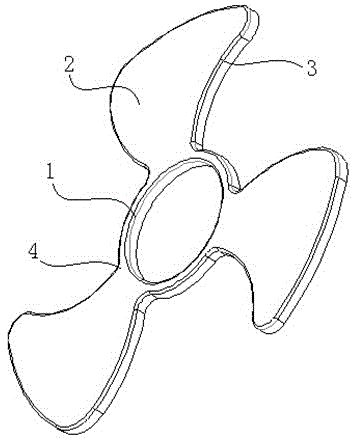

[0033] As a preference, such as image 3 , Figure 4 , Figure 5 As shown, the deflector is a fan blade 7 whose width gradually increases from one end of the connecting installation ring to the other end and has a bending range. outside the mounting ring, image 3 In the form of 3 fan blades, Figure 4 In the form of 4 fan blades, Figure 5 It is in the form of 5 fan blades. In practical application, this kind of structure also causes the deflector to drive the installation ring to rotate due to the impact of the aeration water flow, so as to better clean the membrane surface and avoid the clogging of the membrane surface caused by dirt deposition.

Embodiment 3

[0035] As a preference, such as Figure 6 As shown, the deflector is a straight blade 8 whose width gradually increases from one end of the connecting installation ring to the other end and whose center line passes through the center of the installation ring. Cloth on the outside of the mounting ring. It can also generate turbulence on the surface of the diaphragm to promote the cleaning of the diaphragm itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com