Method and device for generating alloy wire wiegand effect

A technology of wire Wiegand and alloy wire, which is applied in the field of producing the Wiegand effect of alloy wire, can solve the problem of inability to prepare high-amplitude, high-energy sensor products, etc., and achieve the effect of improving sensor performance, performance and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] The alloy wire has a weight ratio of iron, cobalt and vanadium of 49.1%: 43.1%: 7.8%, and a diameter of 0.28mm. The temperature of the heat treatment device is controlled at 865°C±2°C; the included angle α=168° during deformation processing, and the final state is a spiral shape with a diameter of 16cm. The alloy wire is cut into arcs with a length of 12 mm and packed into ceramic tubes. The sensor made of this material is driven by a symmetrical alternating magnetic field, with a coil of 3-5mT, 5k turns, and an amplitude of 8.0V.

example 2

[0032] The alloy wire has a weight ratio of iron, cobalt and vanadium of 49.1%: 43.1%: 7.8%, and a diameter of 0.5mm. The temperature of the heat treatment device is controlled at 960°C±2°C; the included angle α=155° during deformation processing, and the final state is a spiral shape with a diameter of 18cm. The alloy wire is cut into arcs with a length of 22 mm, and packed into ceramic tubes. The sensor made of this material is driven by a symmetrical alternating magnetic field, with a 3-5mT, 5k-turn coil, and an amplitude of 4.5V. The sensor made of this material is driven by a symmetrical alternating magnetic field, with a coil of 3-5mT, 5k turns, and an amplitude of 50V.

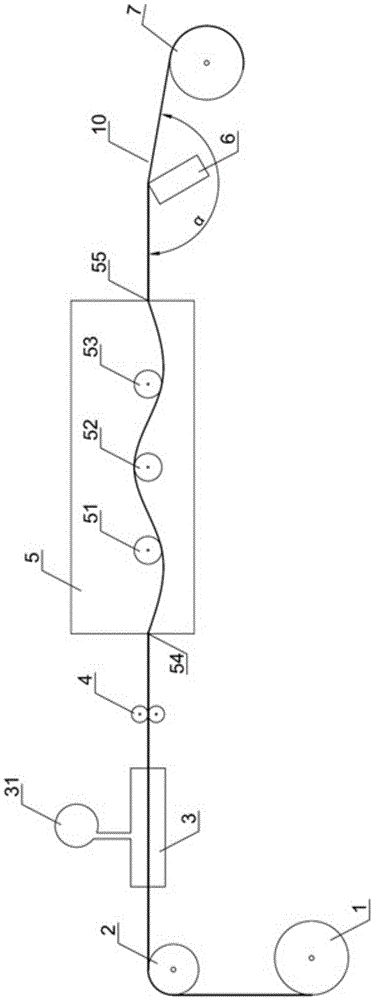

[0033] The structure of a device producing alloy wire Wiegand effect of the present invention is as follows: figure 1 As shown, its composition includes: a feeding tray 1, a speed measuring guide wheel 2, a heat treatment device 3, a pressure guide wheel 4, a traction positioning guide wheel device 5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com