Method for simultaneously synthesizing methyl-ethylbenzene and diethylbenzene by virtue of one-step method

A technology of diethylbenzene and methylethylbenzene, which is applied in the field of chemical synthesis, can solve the problems of high production cost, cumbersome process, and low conversion rate of benzene, and achieve the effects of low cost, fast and simple process, and convenient and fast reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

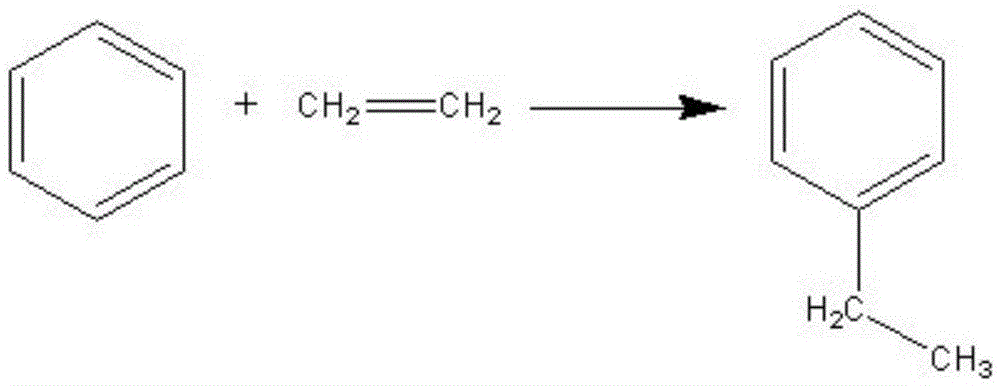

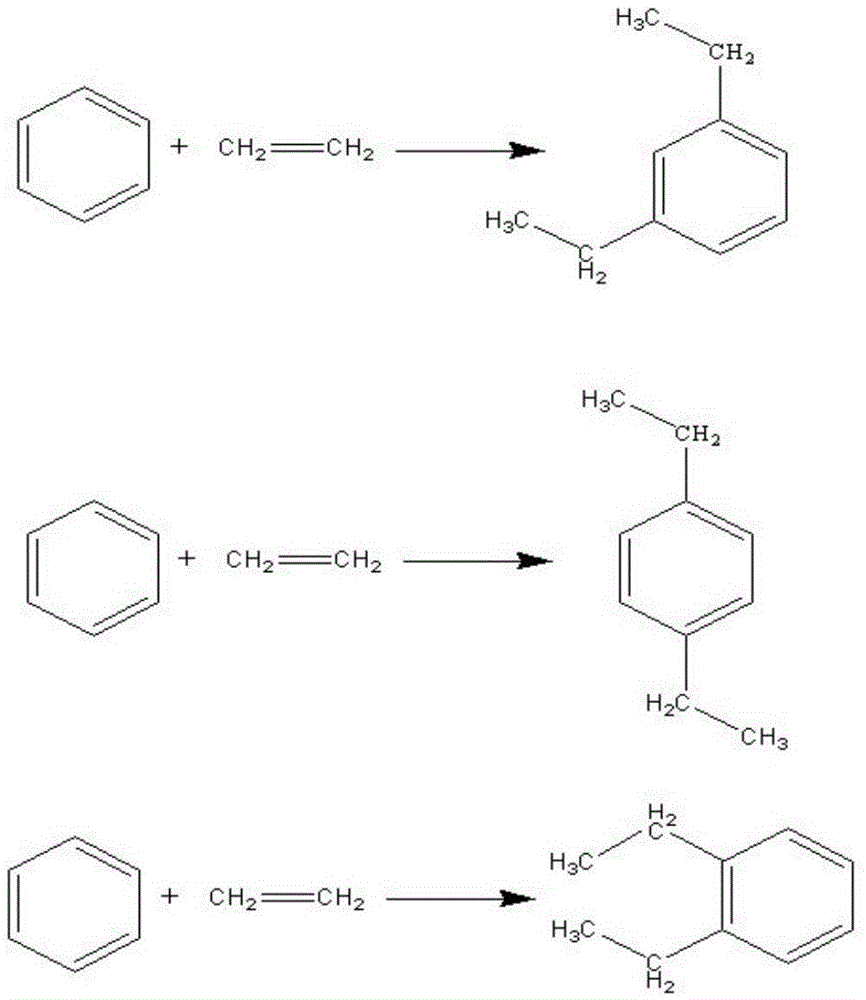

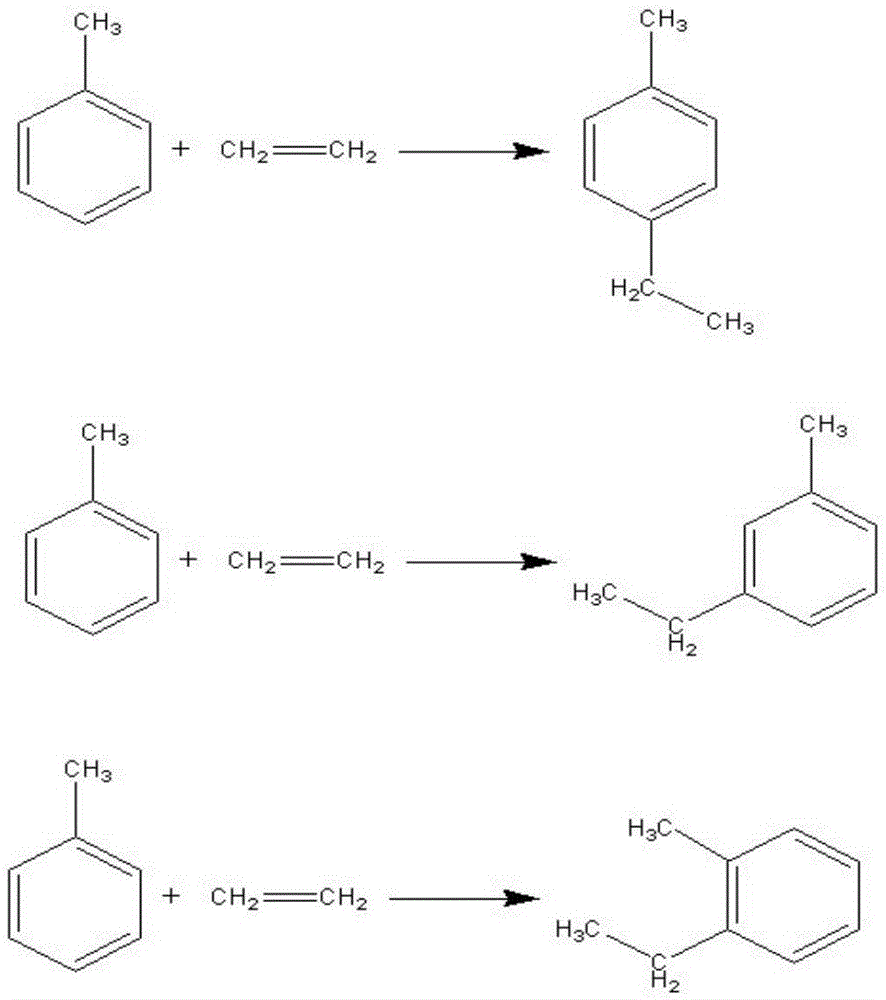

Method used

Image

Examples

Embodiment 1

[0037] Example 1: This example provides a method for simultaneously synthesizing methylethylbenzene and diethylbenzene in one step. The raw materials are benzene, toluene and ethylene, and the ratio of benzene and toluene is 1:1. The method includes a pretreatment stage, a reaction stage and posttreatment stage, the specific steps are as follows:

[0038] (1) Preprocessing stage:

[0039] a) Benzene and toluene are heated up to 130°C through a benzene-toluene heat exchanger, then enter a benzene-toluene gasifier, and enter a heating furnace to be heated to 390°C after gasification;

[0040] b) Put ethylene into the ethylene vaporizer and heat up to 22°C;

[0041] The feed ratio of ethylene to benzene and toluene is 14, wherein the total amount of benzene and toluene includes the part where the mixture of benzene, toluene and ethylbenzene in the subsequent benzene and toluene recovery system enters the benzene and toluene gasifier;

[0042] (2) Reaction stage:

[0043] Pass ...

Embodiment 2

[0052] This embodiment provides a one-step method for simultaneously synthesizing methylethylbenzene and diethylbenzene. The only difference from Example 1 is that the composition ratio of the raw materials and the reaction parameters are slightly different. The raw materials are benzene, toluene and ethylene, and the ratio of benzene to toluene is 1:1.5, the method includes a pretreatment stage, a reaction stage and a postprocessing stage, and the specific steps are as follows:

[0053] (1) Preprocessing stage:

[0054] a) Heating benzene and toluene to 120°C through a benzene-toluene heat exchanger, entering a benzene-toluene gasifier, and entering a heating furnace to heat to 350°C after gasification;

[0055] b) Put ethylene into the ethylene vaporizer and heat up to 18°C;

[0056] The feed ratio of ethylene to benzene and toluene is 17, wherein the total amount of benzene and toluene includes the part where the mixture of benzene, toluene and ethylbenzene in the subseque...

Embodiment 3

[0067] This embodiment provides a one-step method for simultaneously synthesizing methylethylbenzene and diethylbenzene. The only difference from Example 1 is that the composition ratio of the raw materials and the reaction parameters are slightly different. The raw materials are benzene, toluene and ethylene, and the ratio of benzene to toluene is 1:2, the method includes a pretreatment stage, a reaction stage and a postprocessing stage, the specific steps are as follows:

[0068] (1) Preprocessing stage:

[0069] a) Heating benzene and toluene to 140°C through a benzene-toluene heat exchanger, entering the benzene-toluene gasifier, and entering a heating furnace to heat to 430°C after gasification;

[0070] b) Put ethylene into the ethylene vaporizer and heat up to 23°C;

[0071] The feed ratio of ethylene to benzene and toluene is 20, wherein the total amount of benzene and toluene includes the part where the mixture of benzene, toluene and ethylbenzene in the subsequent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com