Method for preparing melamine modified urea-formaldehyde resin adhesive

A technology of urea-formaldehyde resin glue and melamine, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of reducing the performance and service life of wood-based panels, the waterproof performance has not been significantly improved, and artificial The board is easy to absorb moisture and deform, and achieve the effect of reducing expansion rate, good waterproof performance and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

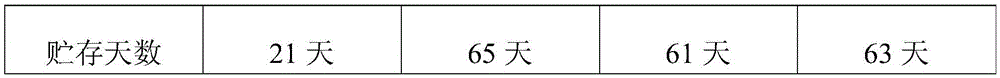

Embodiment 1

[0023] A preparation method of melamine modified urea-formaldehyde resin glue, comprising the following steps:

[0024] (1) First heat the formaldehyde in the container to 35°C, add a NaOH solution with a mass concentration of 35% to adjust the pH value to 8.3, add the first batch of urea and melamine; the addition of the first batch of urea is 33% of the mass of formaldehyde %, the addition of melamine is 6% of the quality of formaldehyde;

[0025] (2) Stop heating when the temperature rises to 70°C, allow it to release heat naturally, then raise the temperature to 85°C, keep time and keep warm for 30 minutes, and slowly add formic acid solution with a mass concentration of 20% within 25-30 minutes, so that The pH value of the reaction solution is adjusted to 5.8. After the pH value is adjusted, measure the viscosity with a four-cup every 5 minutes, and measure the viscosity continuously when approaching the end point. Add NaOH solution with a concentration of 35% to adjust ...

Embodiment 2

[0029] A preparation method of melamine modified urea-formaldehyde resin glue, comprising the following steps:

[0030] (1) First heat the formaldehyde in the container to 35°C, add a NaOH solution with a mass concentration of 35% to adjust the pH value to 8.5, add the first batch of urea and melamine; the addition of the first batch of urea is 33% of the mass of formaldehyde %, the addition of melamine is 6% of the quality of formaldehyde;

[0031] (2) Stop heating when the temperature rises to 70°C, allow it to release heat naturally, then raise the temperature to 88°C, time and keep warm for 30 minutes, and slowly add formic acid solution with a mass concentration of 20% within 25-30 minutes, so that The pH value of the reaction solution is adjusted to 6.3. After the pH value is adjusted, the viscosity is measured with a four-cup every 10 minutes. When approaching the end point, the viscosity is continuously measured. The viscosity of the four-cup at the end is controlled a...

Embodiment 3

[0035] A preparation method of melamine modified urea-formaldehyde resin glue, comprising the following steps:

[0036] (1) First heat the formaldehyde in the container to 35°C, add a NaOH solution with a mass concentration of 35% to adjust the pH value to 8.4, add the first batch of urea and melamine; the addition of the first batch of urea is 33% of the mass of formaldehyde %, the addition of melamine is 6% of the quality of formaldehyde;

[0037] (2) Stop heating when the temperature rises to 70°C, allow it to release heat naturally, then raise the temperature to 86°C, time and keep warm for 30 minutes, and slowly add formic acid solution with a mass concentration of 20% within 25-30 minutes, so that The pH value of the reaction solution is adjusted to 6.0. After the pH value is adjusted, measure the viscosity with the four cups every 8 minutes, and measure the viscosity continuously when approaching the end point. Add NaOH solution with a concentration of 35% to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com