Cell culture biological production device

A production device and cell culture technology, applied in the field of cell culture biological production devices, can solve problems such as low maximum cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Experimental device

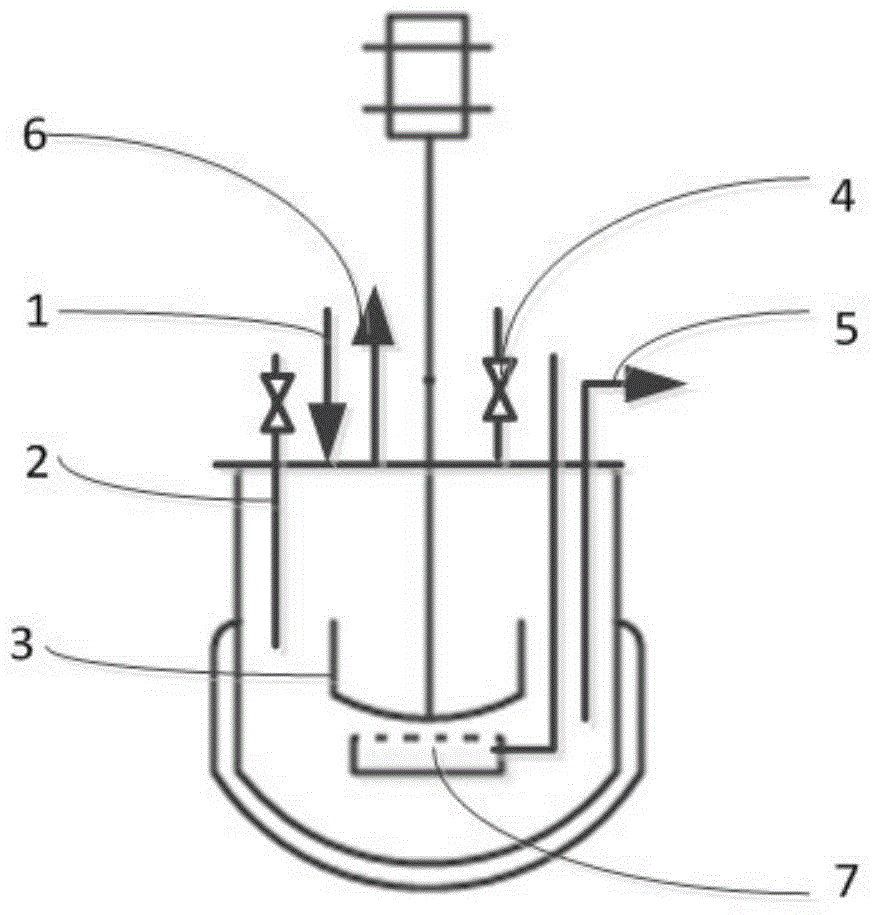

[0050] use Figure 4 The production device shown, where

[0051] 5L bioreactor (working volume 3.5L) and control cabinet: Swiss bio company;

[0052] Aeration tower: self-made

[0053] The body of the aeration tower is a glass tube with an outer diameter of 200mm, a wall thickness of 5mm, and a height of 450mm. The filler is a high borosilicate glass ball with a diameter of 5mm, and the height of the filler layer is 250mm.

[0054] 2. Experimental materials

[0055] Vero cells: from the Shanghai Cell Bank of the Chinese Academy of Sciences;

[0056] Microcarrier cytodexI: American GE Company;

[0057] Basal medium M199 (without NaHCO 3 ): American Hyclone Company;

[0058] M199 basal culture solution: 9.45 parts by weight of the basal medium M199 plus 900 parts by weight of water for injection are dissolved, then the pH is adjusted to 7.20 to 7.30 with a concentration of 5w% sodium bicarbonate aqueous solution, and then diluted to 1000 pa...

Embodiment 2

[0086] 1. Experimental device

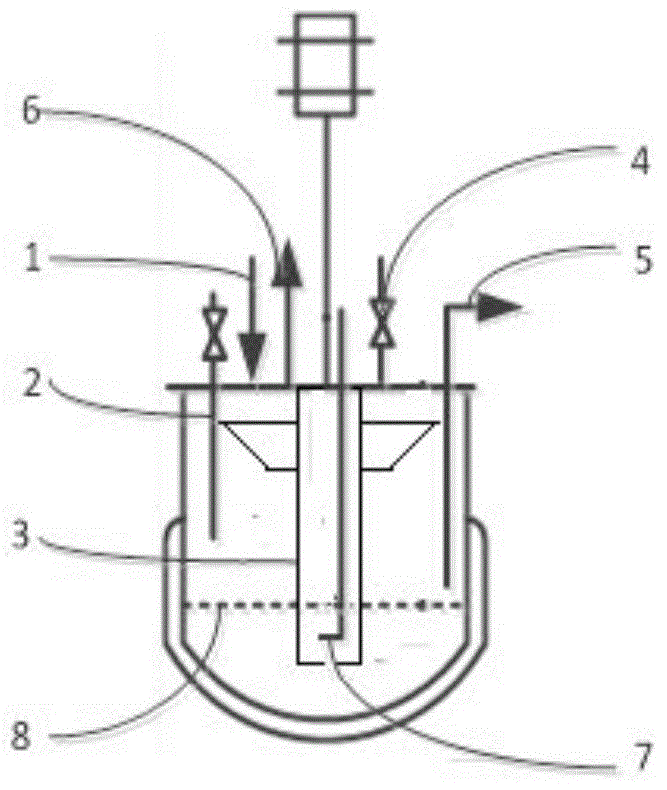

[0087] use Figure 5 The production device shown, where

[0088] 5L bioreactor (working volume 3.5L) and control cabinet: Swiss bio company;

[0089] Aeration tower: self-made

[0090] The body of the aeration tower is a glass tube with an outer diameter of 200mm, a wall thickness of 5mm, and a height of 450mm. The filler is a high borosilicate glass ball with a diameter of 5mm, and the height of the filler layer is 250mm.

[0091] Settler: Homemade

[0092] A glass tube with a diameter of 150 mm and a height of 200 mm has a 60° conical bottom at the bottom, and a 15 mm diameter glass tube connected to the tip of the cone bottom.

[0093] 2. Experimental materials

[0094] Vero cells: from the Shanghai Cell Bank of the Chinese Academy of Sciences;

[0095] Microcarrier cytodexI: American GE Company;

[0096] Basal medium M199 (without NaHCO 3 ): American Hyclone Company;

[0097] M199 basal culture solution: 9.45 parts by weight of the ...

Embodiment 3

[0125] 1. Experimental device

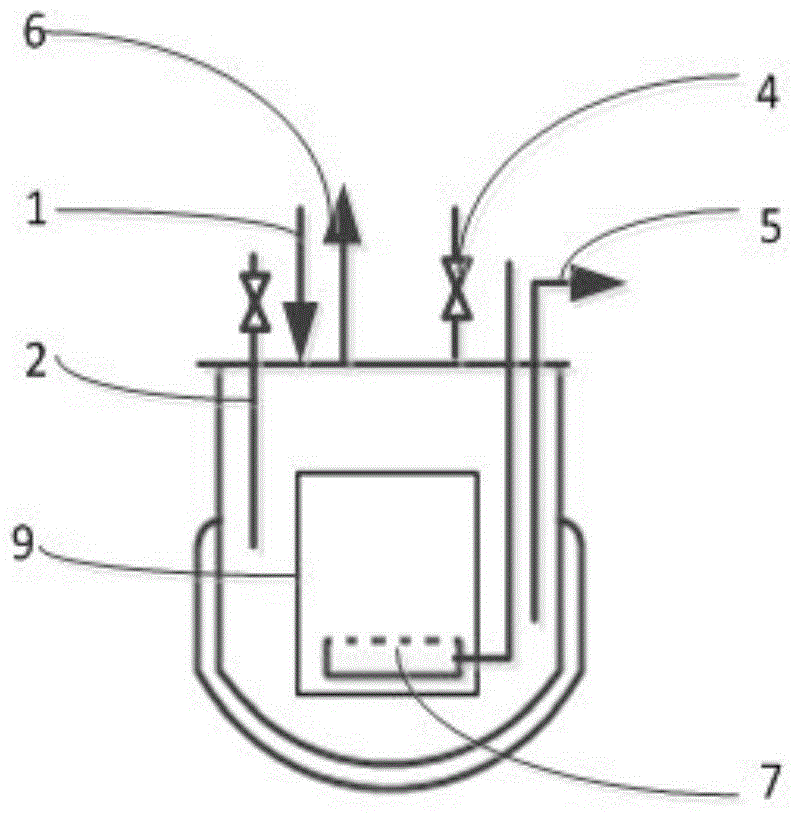

[0126] use Image 6 The production device shown, where

[0127] 5L bioreactor (working volume 3.5L) and control cabinet: Swiss bio company;

[0128] Aeration tower: self-made

[0129] The body of the aeration tower is a glass tube with an outer diameter of 200mm, a wall thickness of 5mm, and a height of 450mm. The filler is a high borosilicate glass ball with a diameter of 5mm, and the height of the filler layer is 250mm.

[0130] Settler: Homemade

[0131] A glass tube with a diameter of 150 mm and a height of 200 mm has a 60° conical bottom at the bottom, and a 15 mm diameter glass tube connected to the tip of the cone bottom.

[0132] Cell debris separator: self-made hydrocyclone, the shape is as follows:

[0133] A glass tube with a diameter of 25mm and a glass tube with an inner diameter of 15mm. The upper part is sealed with flat glass, and the inner tube grows out; the inner and outer FRP diameters form a uniform ring; the lower part i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com