Combined tamping construction method of aluminum electrolytic cell lining paste

A technology of lining paste and aluminum electrolytic cells, which is applied in the field of electrolytic aluminum, can solve the problems of low bonding strength, local delamination, and insufficient tamping compactness, so as to enhance bonding strength, improve compactness, and solve local problems. Effects of Stratified Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

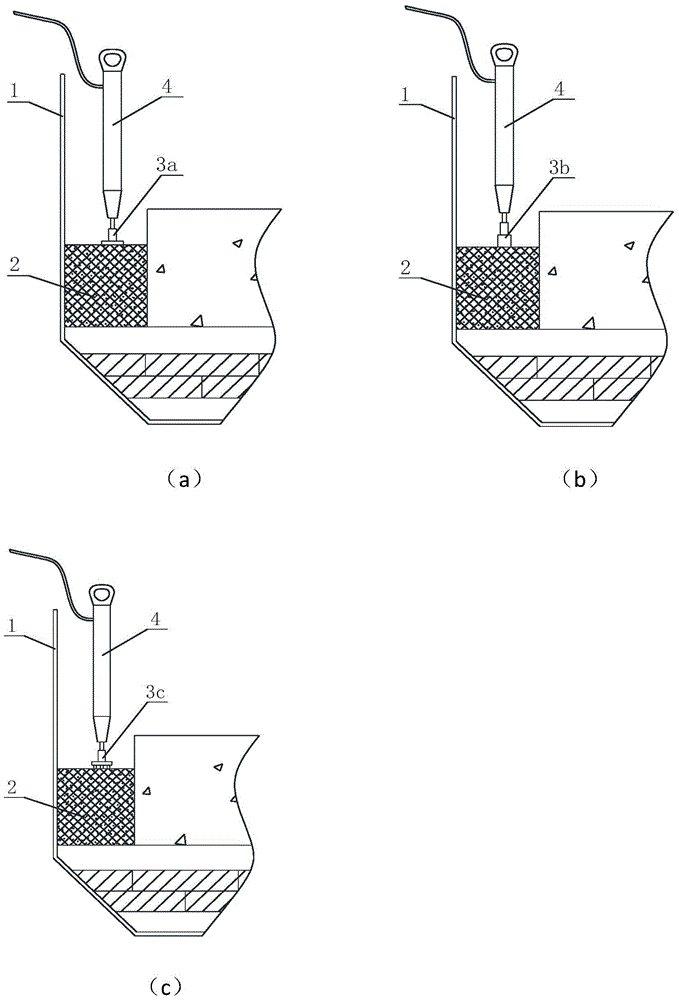

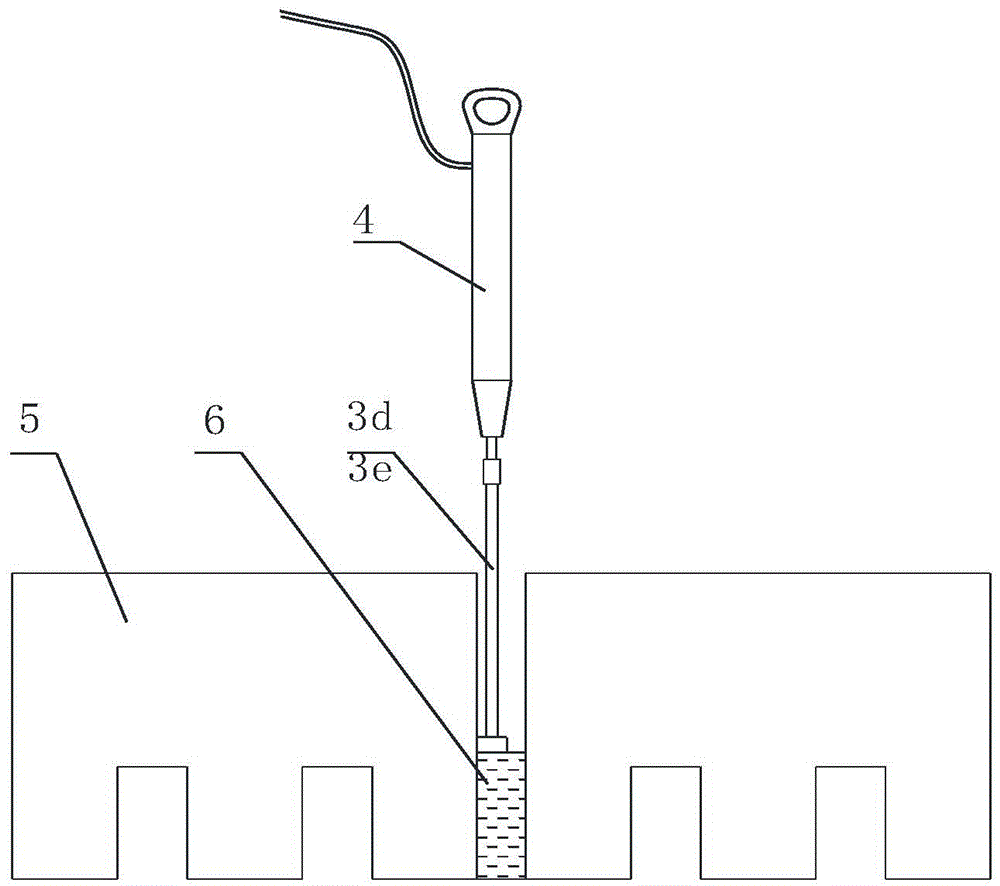

[0019] A combined tamping construction method for the lining paste of an aluminum electrolytic cell. According to the distribution position and area size of the electrolytic cell lining paste, the construction is carried out in two tamping methods: the paste area around the tank is larger, It is a flat type of tamping; the gap between the cathode carbon blocks is small, so the tamping area is small, and it is an interstitial type of tamping.

[0020] 1. Flat tamping method of paste around the tank:

[0021] The paste (2) around the tank is close to the tamping area of the electrolytic cell body (1), and the tamping area is relatively large. The paste needs to be layered and tamped tightly, and the thickness of the layers must meet the quality requirements.

[0022] The tamping machine (4) is equipped with different hammer heads for operation: the flat hammer head (3a) has a large hitting surface and a light hammer head, which is used for preliminary paving of the paste, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com