A kind of flame-retardant melt-blown nonwoven material and preparation method thereof

A non-woven material and melt-blown technology, which is applied in the manufacture of non-woven fabrics, fire-resistant and flame-retardant filaments, textiles and papermaking, etc., can solve the problems of poor flame retardancy, achieve good flame-retardant durability, promote development, and expand use range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

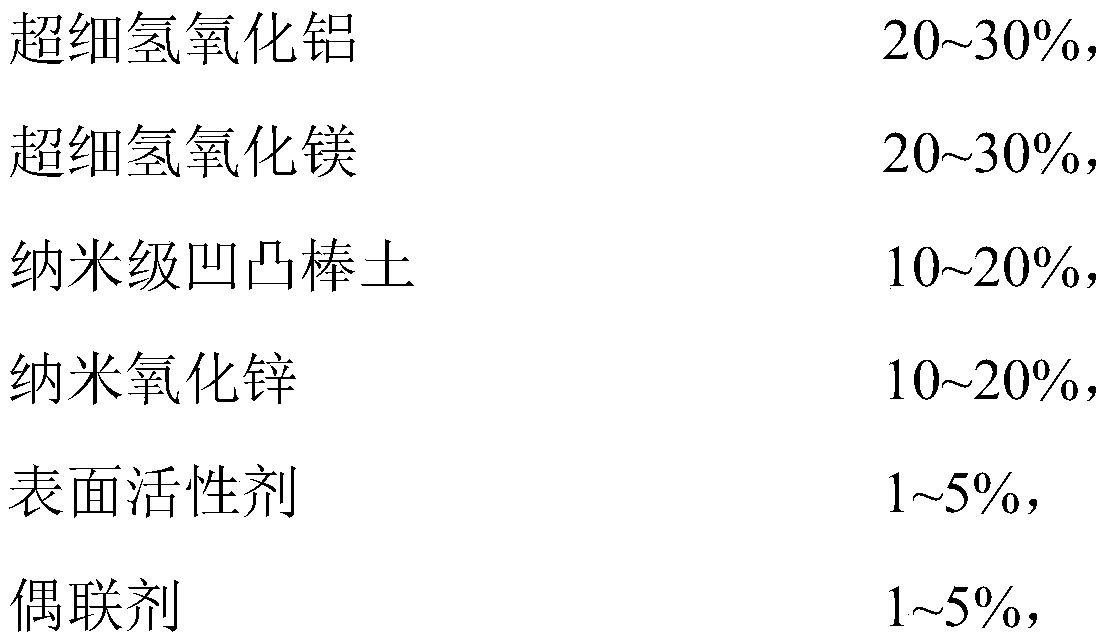

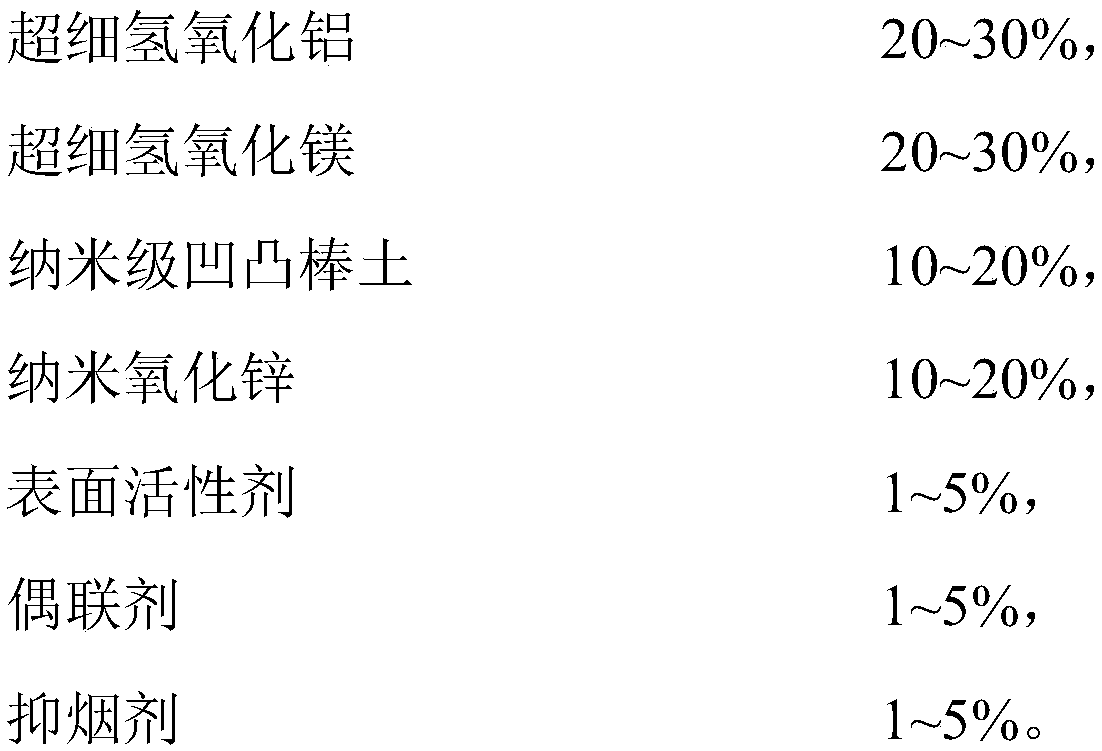

[0029] 20% by mass of ultrafine aluminum hydroxide, 30% of ultrafine magnesium hydroxide, 20% of nano-scale attapulgite, 20% of nano-zinc oxide, 3% of surfactant, 3% of coupling agent Add 4% smoke suppressant to a high-speed mixer, heat up and mix at a high speed to obtain a composite flame retardant; wherein, the particle size of ultrafine aluminum hydroxide and ultrafine magnesium hydroxide is 20-100nm, and nano-scale attapulgite The particle size of the nano-zinc oxide is 50-100nm, the particle size of the nano-zinc oxide is 10-50nm, the surfactant is a carboxylate anionic surfactant, the coupling agent is a silane coupling agent, and the smoke suppressant is molybdenum trioxide .

[0030] Blend and granulate the composite flame retardant and PBT chips prepared above at 220°C to make flame-retardant melt-blown PBT chips, wherein the composite flame retardant accounts for 10% by mass; the flame-retardant melt-blown PBT The slices are fed into the screw extruder for melt-blo...

Embodiment 2

[0033] 30% by mass of ultrafine aluminum hydroxide, 30% of ultrafine magnesium hydroxide, 15% of nano-scale attapulgite, 15% of nano-zinc oxide, 4% of surfactant, 3% of coupling agent Add 3% smoke suppressant to a high-speed mixer, heat up and mix at a high speed to obtain a composite flame retardant; wherein, the particle size of ultrafine aluminum hydroxide and ultrafine magnesium hydroxide is 50-150nm, and nano-scale attapulgite The particle size of the zinc oxide is 50-100nm, the particle size of the nano-zinc oxide is 50-100nm, the surfactant is a carboxylate anionic surfactant or a sulfate anionic surfactant, and the coupling agent is a silane coupling agent Or titanate coupling agent, smoke suppressant is molybdenum trioxide or ammonium octamolybdate.

[0034] Blend and granulate the composite flame retardant and PBT chips prepared above at 230°C to make flame-retardant melt-blown PBT chips, wherein the composite flame retardant accounts for 15% by mass; the flame-retar...

Embodiment 3

[0037] 30% by mass of ultrafine aluminum hydroxide, 30% of ultrafine magnesium hydroxide, 20% of nano-scale attapulgite, 10% of nano-zinc oxide, 2% of surfactant, 3% of coupling agent Add 5% smoke suppressant to a high-speed mixer, heat up and mix at high speed to obtain a composite flame retardant; among them, the particle size of ultrafine aluminum hydroxide and ultrafine magnesium hydroxide is 300-500nm, and nano-scale attapulgite The particle size of the nano-zinc oxide is 100-200nm, the particle size of the nano-zinc oxide is 70-100nm, the surfactant is a carboxylate anionic surfactant or a sulfate anionic surfactant, and the coupling agent is a silane coupling agent Or titanate coupling agent, smoke suppressant is molybdenum trioxide or ammonium octamolybdate.

[0038] Blend and granulate the composite flame retardant and PBT chips prepared above at 250°C to make flame-retardant melt-blown PBT chips, wherein the composite flame retardant accounts for 15% by mass; the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com