Formaldehyde-free textile color-fixing agent with high color-fixing effect

A technology of color effect and color fixing agent, which is applied in the direction of textiles, papermaking, and dyeing methods, and can solve the problems of unsatisfactory wet rubbing fastness and washing fastness, the influence of reactive dyes on shade, and poor dye binding force, etc. , to achieve the effect of improving color fixing effect, good water solubility and permeability, and reducing water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

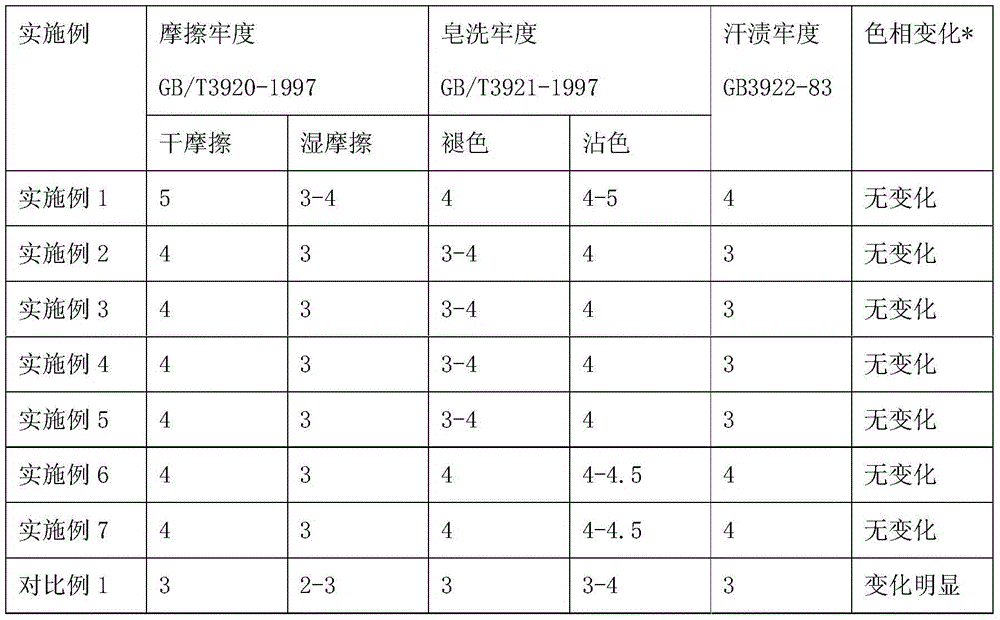

Examples

Embodiment 1

[0014] Example 1: An aldehyde-free high-fixing effect textile fixing agent, which includes the following mass percentage of raw materials: amino-terminated hyperbranched compound HBP-NH 2 15%, polydimethyldiallylammonium chloride 2%, 3-chloro-2-hydroxypropylmethyldiallylammonium chloride 3%, fatty acid polyethylene glycol ester 6%, the balance is Deionized water.

[0015] Further, the preparation method of the textile fixing agent without aldehyde and high fixing effect includes the following steps:

[0016] 1) Prepare the raw materials according to the mass percentage;

[0017] 2) The amino-terminated hyperbranched compound HBP-NH 2 Place the fatty acid polyethylene glycol ester in an appropriate amount of deionized water and stir until all are dissolved;

[0018] 3) Add polydimethyldiallylammonium chloride and 3-chloro-2-hydroxypropylmethyldiallylammonium chloride to the solution obtained in step 2, and heat the solution to 50°C, well mixed;

[0019] 4) Add the remaining amount of d...

Embodiment 2

[0020] Example 2: An aldehyde-free high-fixing effect textile fixing agent, which includes the following mass percentage of raw materials: amino-terminated hyperbranched compound HBP-NH 2 10%, polydimethyldiallylammonium chloride 1%, 3-chloro-2-hydroxypropylmethyldiallylammonium chloride 2%, fatty acid polyethylene glycol ester 3%, the balance is Deionized water.

[0021] Furthermore, the specific steps of the preparation method of the textile fixing agent without aldehyde and high fixing effect are the same as in Example 1.

Embodiment 3

[0022] Example 3: An aldehyde-free high-fixing effect textile fixing agent, which includes the following mass percentage of raw materials: amino-terminated hyperbranched compound HBP-NH 2 20%, polydimethyldiallylammonium chloride 3%, 3-chloro-2-hydroxypropylmethyldiallylammonium chloride 5%, fatty acid polyethylene glycol ester 8%, the balance is Deionized water.

[0023] Furthermore, the specific steps of the preparation method of the textile fixing agent without aldehyde and high fixing effect are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com