Scraper-controllable multifunctional wall scraping device

A wall scraper and multi-functional technology, which is applied in the direction of cleaning equipment, wellbore/well components, earthwork drilling and production, etc., can solve problems such as impassability, downhole accidents, and failure to raise, and achieve the effect of eliminating hidden safety hazards in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

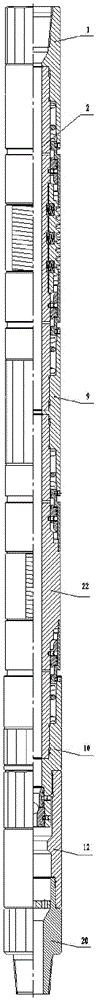

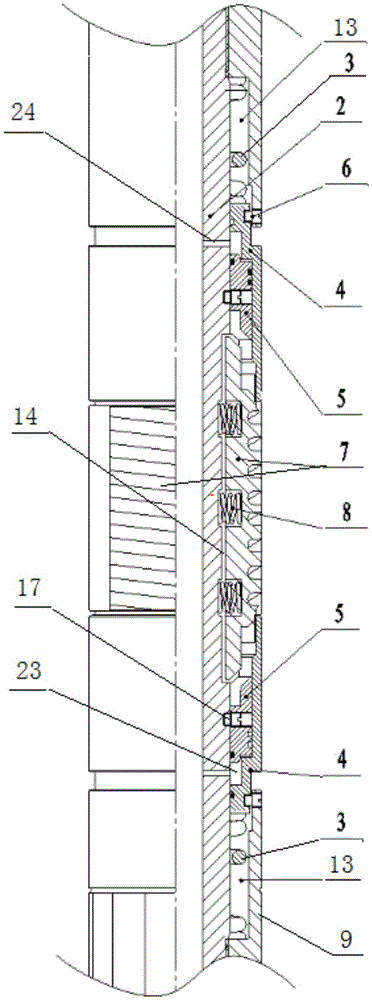

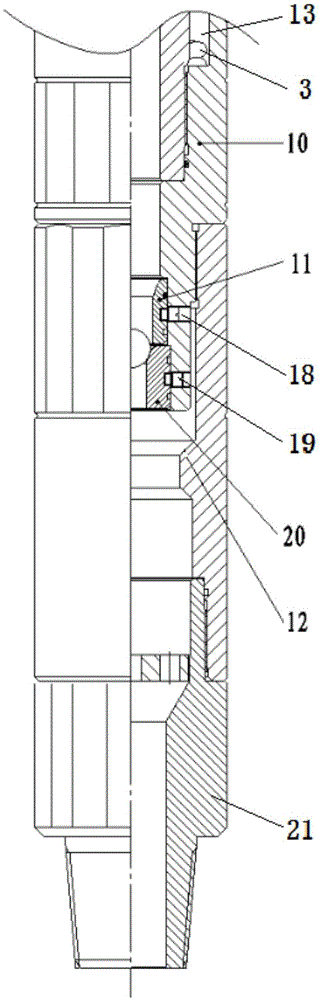

[0021] combined with Figure 1-7 An embodiment of the present invention is described.

[0022] A liquid multifunctional wall scraper with a retractable scraper, comprising an upper joint 1 and a lower joint 21 with a through hole in the center, the lower end of the upper joint 1 is connected with a first tubular scraper seat 2, and the first tubular The lower end of the scraper seat 2 is connected with a second tubular scraper seat 22 through an intermediate sleeve 9, and the lower end of the second tubular scraper seat 22 is connected with a ball socket 12 through a ball joint 10, and the ball socket The lower end of 12 is connected with lower joint 21;

[0023] The lower end of the upper joint 1, the two ends of the intermediate sleeve 9 and the upper end of the ball joint 10 all have an annular groove 13, and the first spring 3 is installed in the axial direction of the annular groove 13; Three strip-shaped grooves 14 are evenly distributed along the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com