Hollow-shaft ram-rotor based on shock wave compression technology

A compression technology, ram compression technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem that the power-to-weight ratio of gas turbines has no essential influence, and the volume and weight of the compression system Larger, lower total compression efficiency and other issues, to achieve the effect of light weight, high compression efficiency and high boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

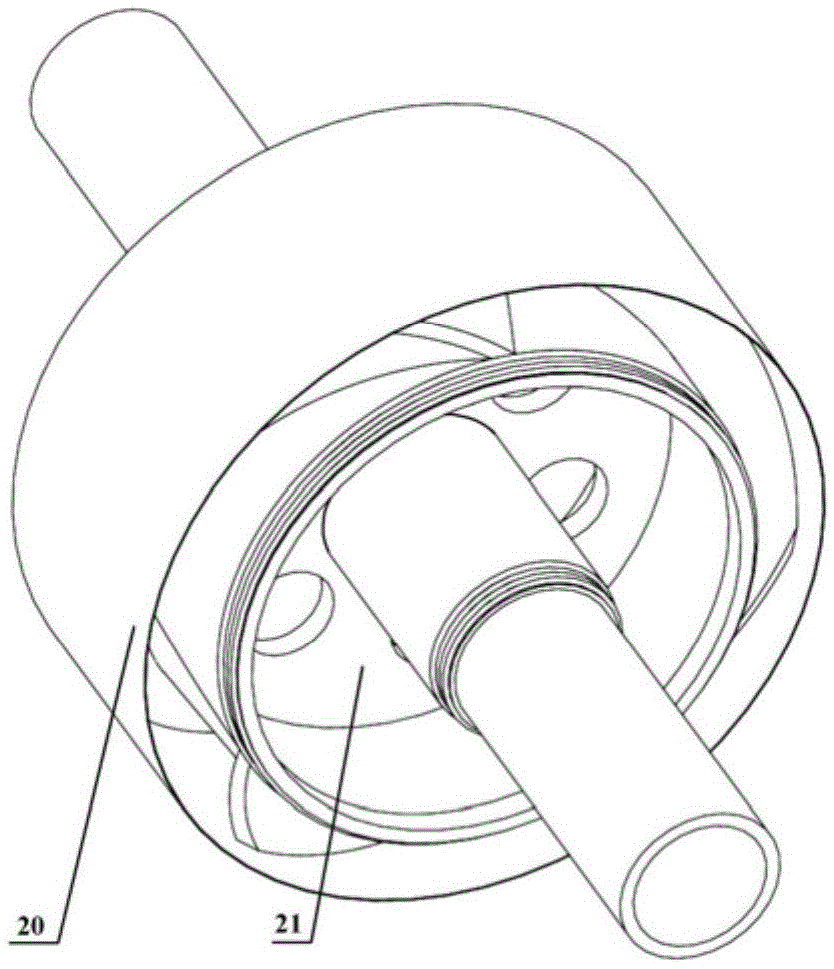

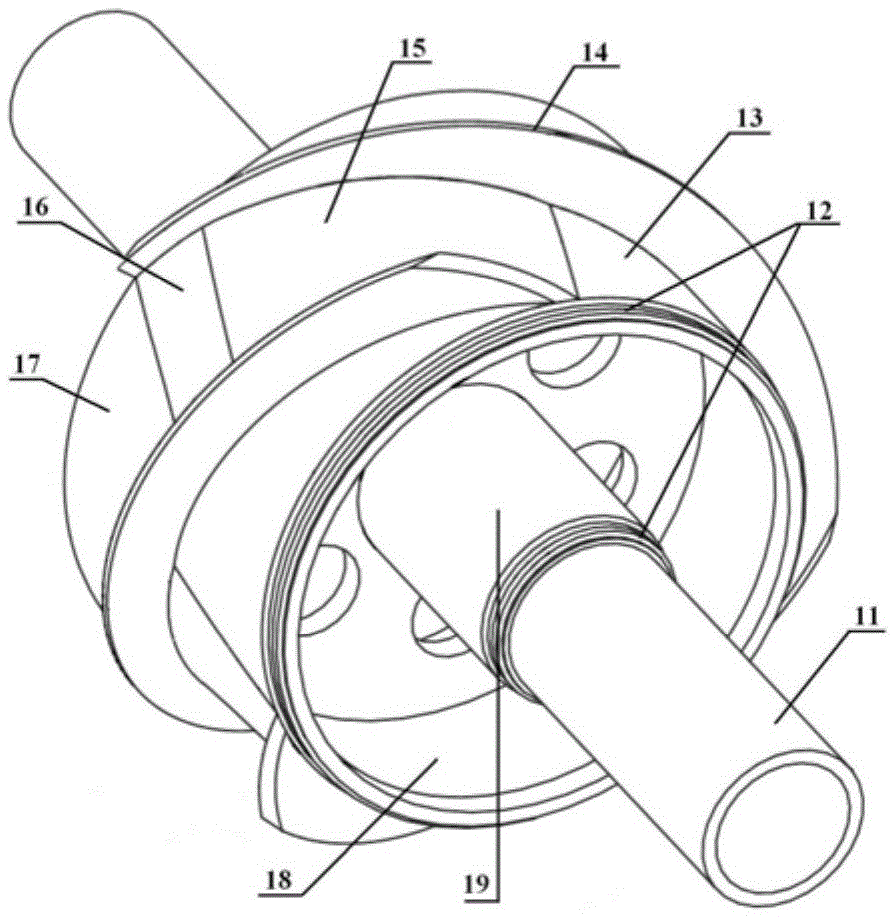

[0027] Such as figure 1 with figure 2 The shown hollow shaft rotary stamping compression rotor based on shock wave compression technology includes: a hollow shaft 11, a wheel assembly that rotates synchronously with the hollow shaft 11, and an outer casing 20 that is placed outside the wheel assembly;

[0028] Wherein, the outer wall surface of the outer edge 13 of the roulette assembly is evenly distributed with a plurality of spiral partitions 14, and the installation angle of each spiral partition 14 is the same;

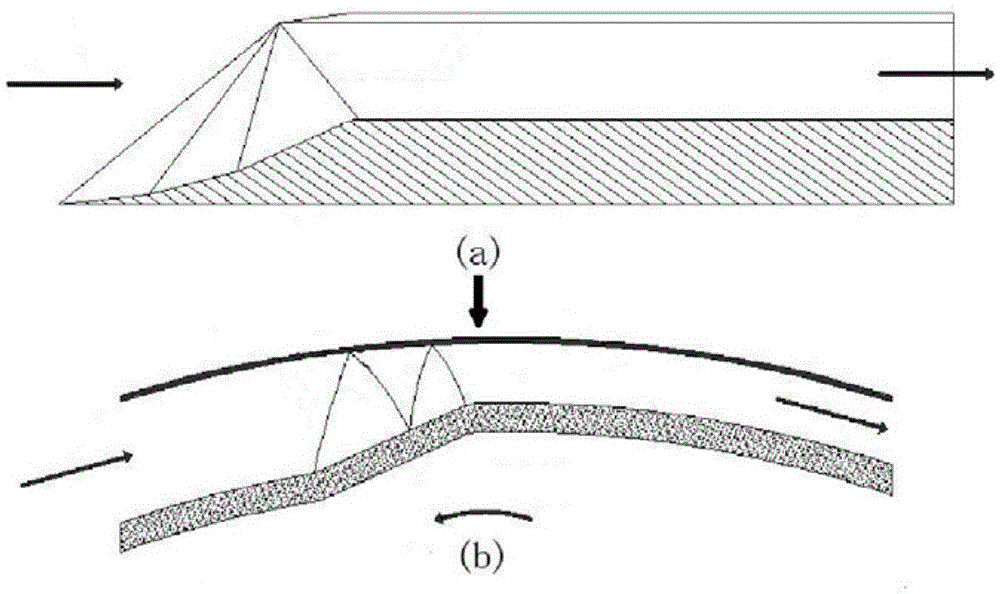

[0029] The gap between every two adjacent spiral partitions 14 forms an air intake channel, and each air intake channel is provided with an airflow compression section 15, a throat isolation section 16 and a triangular outlet extension section 17 in sequence from the inlet end to the outlet end. ;

[0030] Among them, the airflow compression section 15 is a compressed air channel with a gradually narrowing radial gap; the throat isolation section 16 is an equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com