Fluid damping device used for coping with pipeline pressure jump

A technology of fluid damping and pipeline pressure, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of pipeline safety and smooth operation threats, difficult installation and maintenance, high equipment manufacturing costs, etc., to achieve structural The effect of simplicity, ease of maintenance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

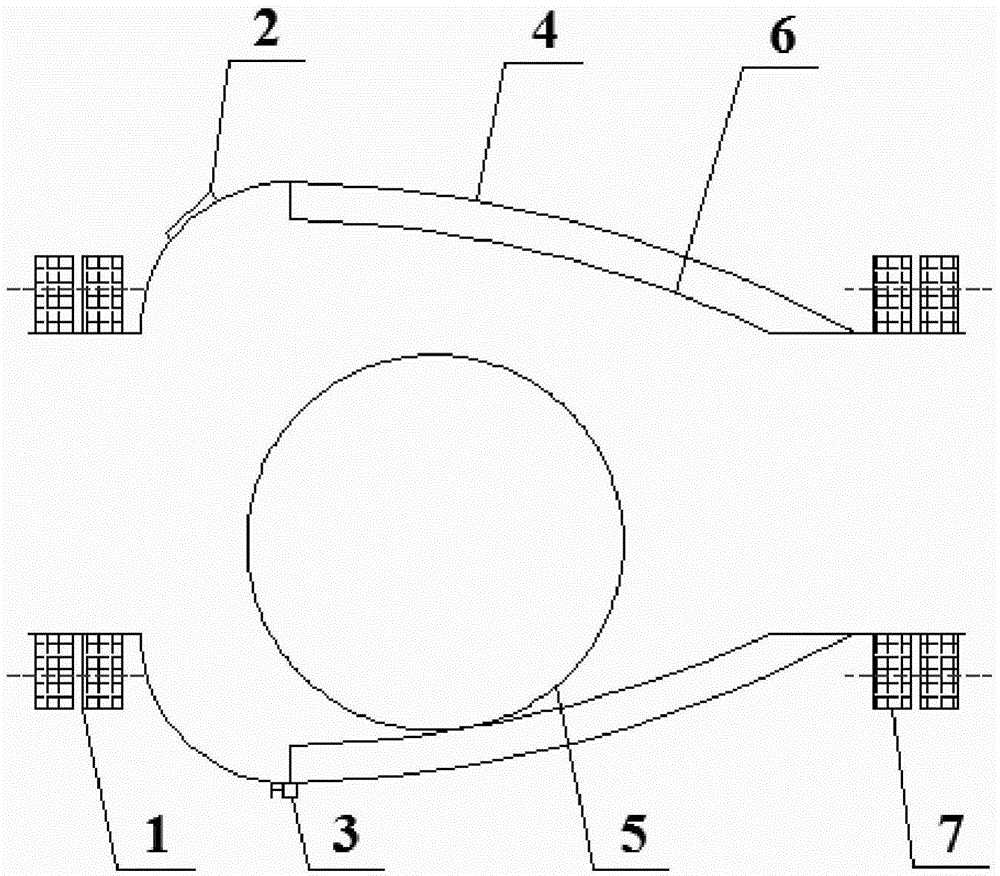

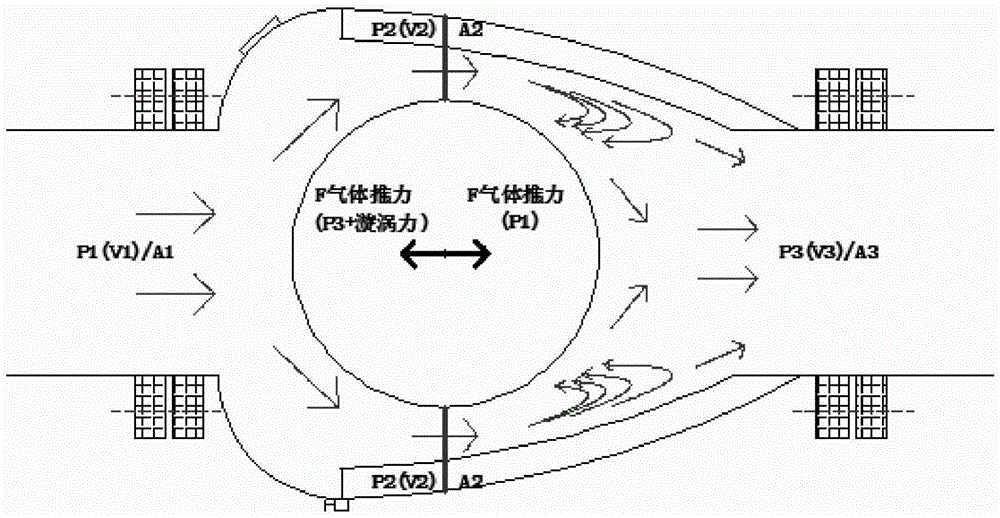

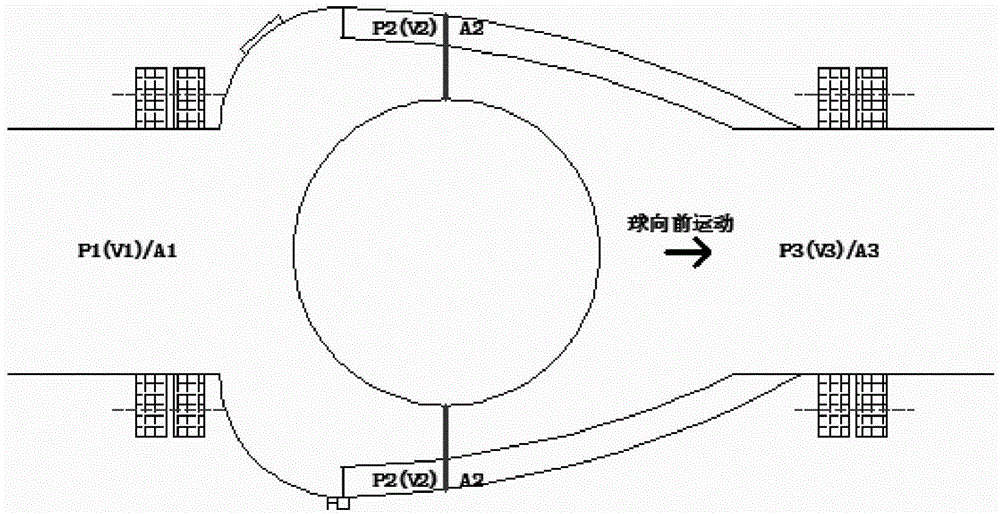

[0034] Such as figure 1 As shown, a fluid damping device to cope with sudden changes in pipeline pressure includes a window 2, a drain valve 3, a box 4, a plastic ball 5, and a grooved tube 6. The shape of the box 4 is formed by rotating an oval curve around the axis for one circle. The two ends of the rotary body are coaxially provided with an outlet, an inlet, and an upstream connecting flange 1 and a downstream connecting flange 7 for connecting the upper and lower gas pipelines. The inner wall of the box body 4 near the outlet is uniformly There are several grooved pipes 6 pointing to the outlet at intervals. The arc of the grooved pipes 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com