Imaging apparatus and method for detecting object surface micro deformation through machine vision

A technology of machine vision detection and object surface, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inability to image, and achieve the effect of simple and easy technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

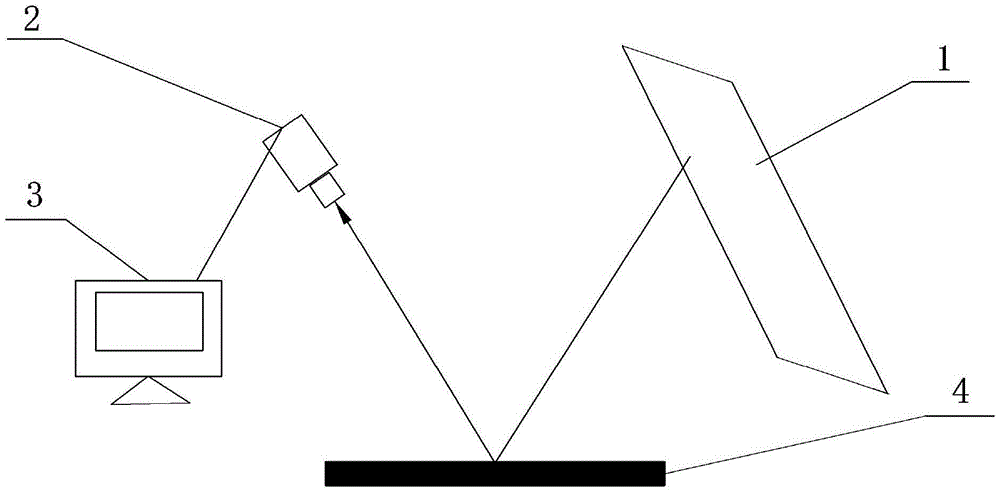

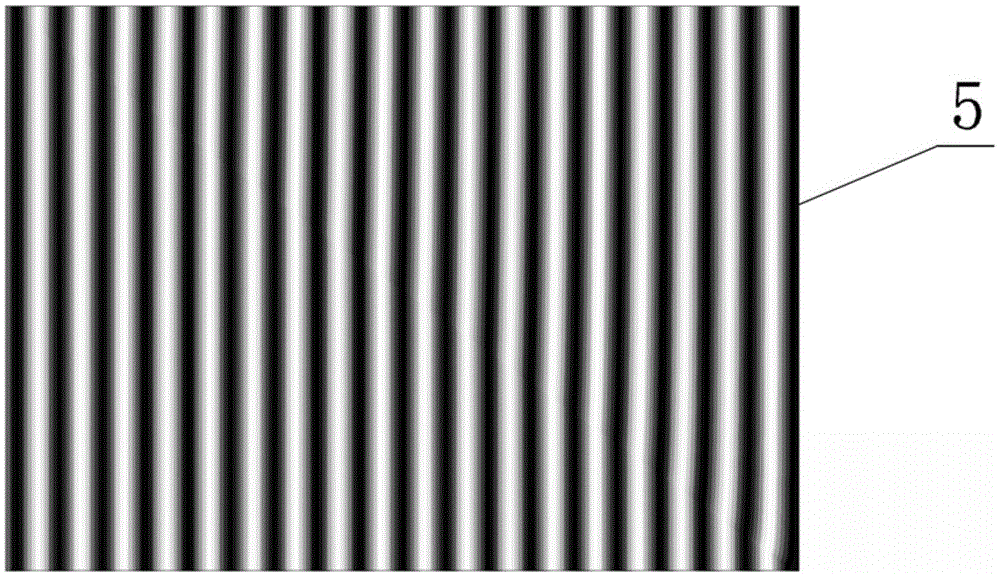

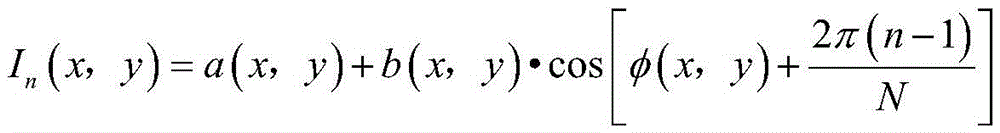

[0024] Such as figure 1 , 2 shown. The invention discloses an imaging device for machine vision detection of micro-deformation on the surface of an object, comprising a display 1, a camera 2 and a computer 3; the display 1 is used to modulate the grating stripe light 5 (such as black and white vertical stripes) that produces a sinusoidal phase shift The camera 2 and the display 1 are arranged above the surface of the detected object 4; the grating stripe light 5 of the display 1 is irradiated to the entire upper surface of the detected object 4, and a fringe image is formed on the entire upper surface of the detected object 4, The camera 2 is used to collect the fringe image reflected on the surface of the detected object 4 and transmit it to the image analysis system of the computer 3 . The display 1 is a liquid crystal display display. The camera 2 is an industrial camera.

[0025] The camera 2 and the display 1 are installed above the detected object 4 in a V shape.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com