Spring circuit breaker fault simulation device

A technology of circuit breaker failure and simulation device, applied in circuit breaker testing, measuring devices, instruments, etc., can solve problems such as the decline of spring energy storage capacity, staying in the theoretical stage, and the lack of experimental data support for the failure simulation model of the circuit breaker. , to achieve the effect of changing the stretch length and reducing the difficulty of obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

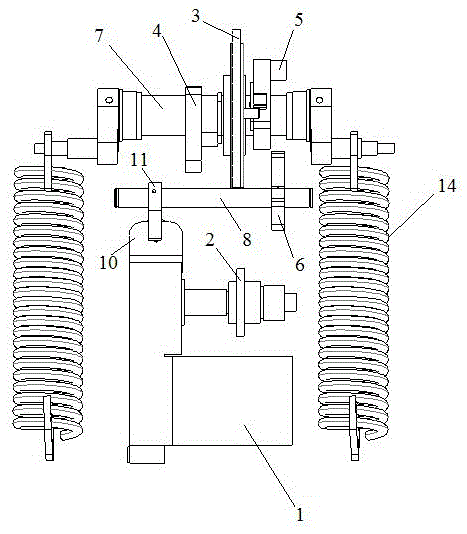

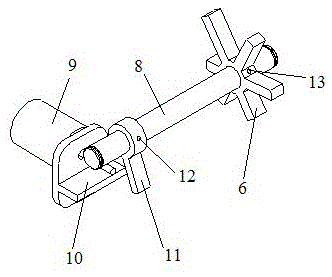

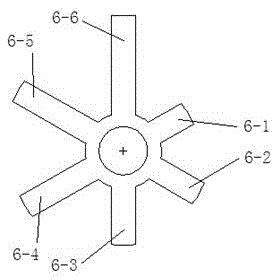

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-Figure 3 As shown, a spring circuit breaker fault simulation device includes energy storage motor 1, small sprocket 2, large sprocket 3, cam 4, limit pin 5, holding detent 6, main shaft 7, synchronous shaft 8, closing Electromagnet 9, closing spring 14, release holding piece 11, fixed seat 10. The circuit breaker fault simulation device adopts the spring operating mechanism form of the ZN-63 circuit breaker, the energy storage motor 1, the small sprocket 3, the large sprocket 3, the cam 4, the limit pin 5, the main shaft 7, the closing Electromagnet 9, closing spring 14 and synchronous shaft 8 are fixedly assembled according to the corresponding position and mode in the ZN-63 circuit breaker. The holding detent 6 has 6 limit blocks with different lengths, the length of the first limit block 6-1 is equal to that of a normal circuit breaker, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com