Method for detecting anti-explosion performance of mining mobile rescue capsule

A rescue cabin and mobile technology, applied in mining equipment, earth cube drilling, special data processing applications, etc., can solve problems such as failure to consider fluid-solid coupling, and achieve comprehensive and detailed analysis of data, and the effect of real and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Embodiment 1. A method for detecting the anti-explosion performance of a mine-used movable rescue cabin described in this embodiment is carried out according to the following steps:

[0039] 1. Using ANSYS / LS-DYNA finite element software to establish a three-dimensional finite element model of the shell of the mine-used movable rescue chamber;

[0040] 2. Use ANSYS / LS-DYNA finite element software to carry out numerical simulation in real underground roadway environment and gas explosion flow field environment;

[0041] 3. Determine the boundary conditions;

[0042] 4. Determine the materials of the components of the mine movable rescue cabin;

[0043] 5. Numerical simulation of gas explosion flow field environment;

[0044] 6. Using the fluid-solid coupling method, analyze the dynamic response of the mine-used movable rescue cabin under the shock wave load of the gas explosion;

[0045] Six (1), analyze the overall dynamic response of the mine-used movable rescue cha...

specific Embodiment approach 2

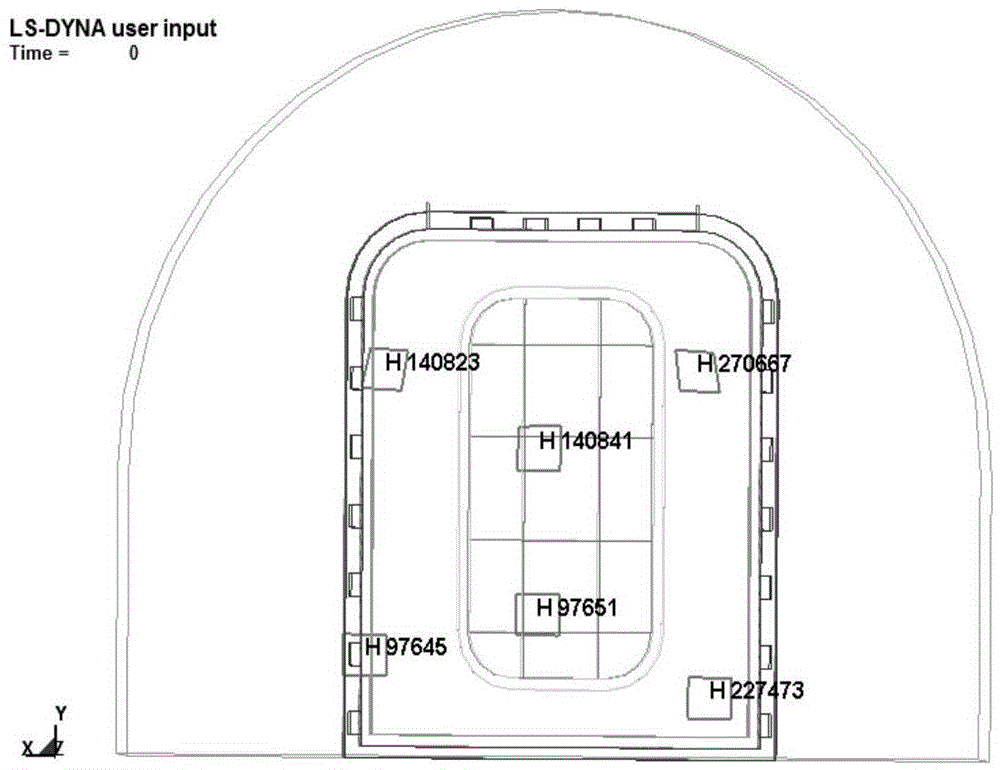

[0051] Specific embodiment 2. This embodiment is a further description of the method for detecting the anti-explosion performance of a mine movable rescue cabin described in specific embodiment 1. Step 1 utilizes ANSYS / LS-DYNA finite element software to establish mine The specific process of the three-dimensional finite element model of the movable rescue cabin shell is as follows:

[0052] Modeling is carried out based on the actual size of the KJYF-96 / 12 mine-used movable rescue cabin. The skin, flange and end plate of the basic cabin are meshed with the thin shell element SHELL163, and the size of the shell element is 40mm; the main cabin Doors and escape doors are meshed with solid element SOLID164, and the size of the solid element is 40mm.

specific Embodiment approach 3

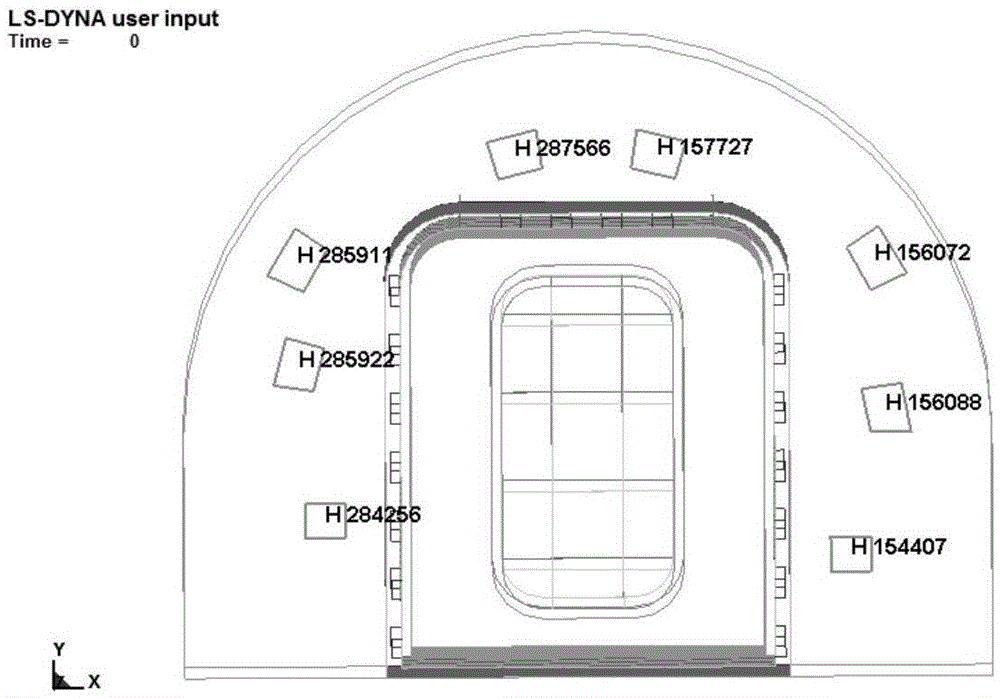

[0053]Embodiment 3. This embodiment is a further description of the method for detecting the anti-explosion performance of a mine-used movable rescue cabin described in Embodiment 1 or 2. Step 2 uses ANSYS / LS-DYNA finite element software to perform The specific process of the numerical simulation in the real underground tunnel environment and the gas explosion flow field environment is as follows:

[0054] The roadway is horizontally arranged, with a total length of 130m, divided into four sections, the first section: the source of the explosion accident, the interior is filled with a gas-air mixture with a concentration of 9.5%, and the length is 28m; the second section: the explosion shock wave propagation section, It is a pure air section with a length of 72m and the interior is filled with air; the third section: the fluid-solid coupling section between the air and the mine-used movable rescue capsule, with a length of 13m; the fourth section: the diffusion section, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com