A low-energy rotary drive device for space-borne microwave switches

A rotary drive, space-borne microwave technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve the problems of low driving force, unstable contact resistance, total reflection of microwave signals, etc., to improve the reed retention force and lock. The effect of preventing torque, improving reliability and stability, and improving anti-vibration and shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

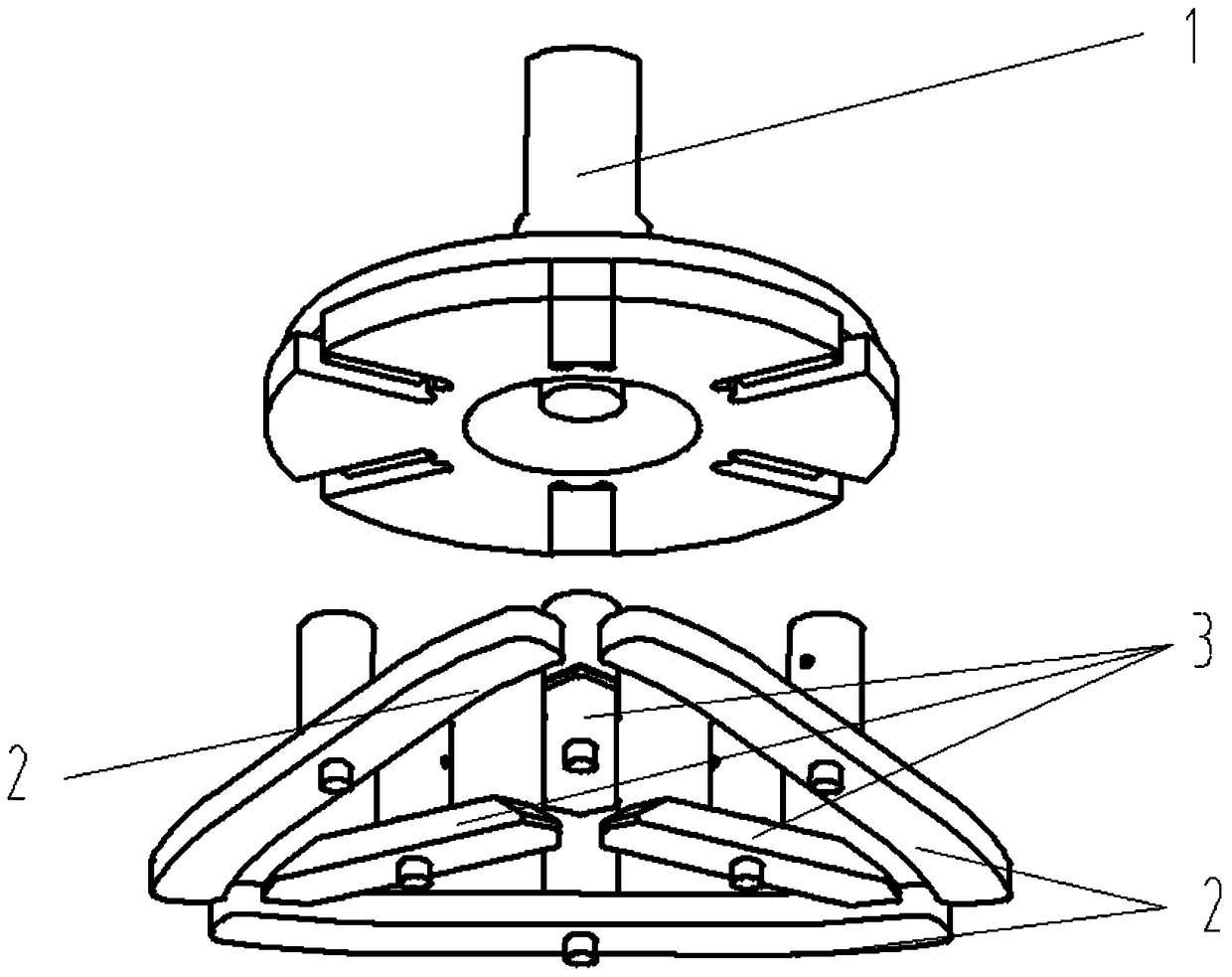

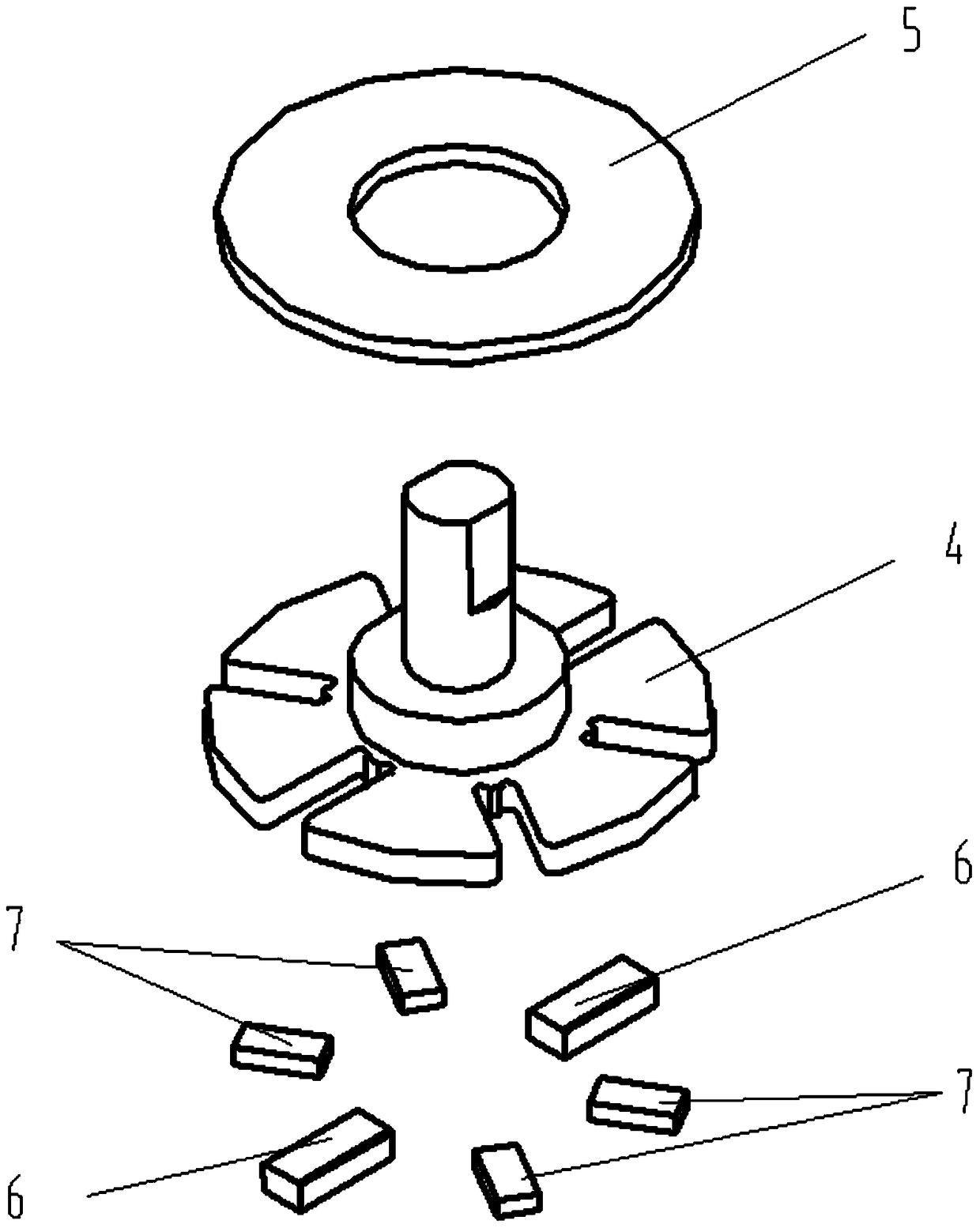

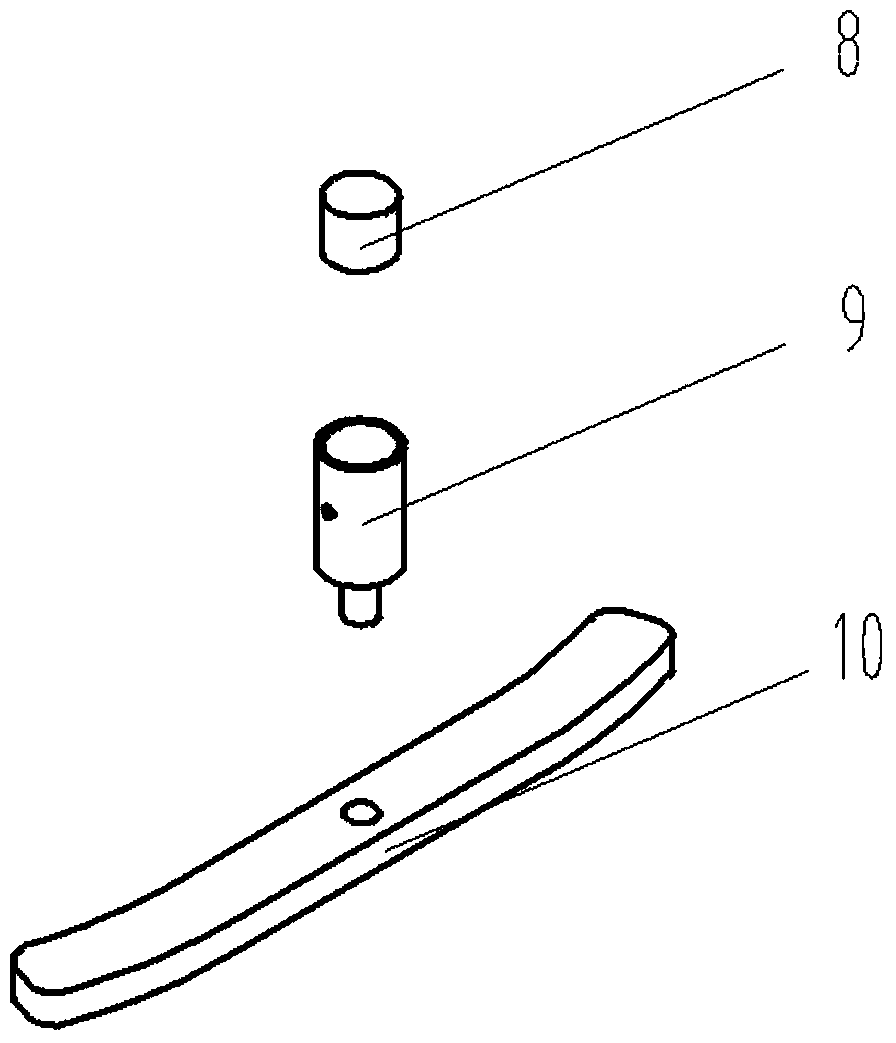

[0015] Such as figure 1 As shown, a low-energy rotary drive device for an on-board microwave switch includes a rotor set 1 , a first reed set 2 and a second reed set 3 . Such as figure 2 As shown, the rotor set 1 includes a rotor shaft 4, a rotor spacer 5, a first driving magnet 6, and a second driving magnet 7; the bottom of the rotor shaft 4 is disc-shaped, and the bottom disc has a number of concave holes along the circumferential direction. Groove, there is a cylindrical structure in the middle of the disk, and the cylindrical structure is composed of two cylinders with different diameters to form a step; the rotor gasket 5 is a circular or elliptical ring, which is sleeved on the cylindrical structure in the middle of the rotor shaft 4 and fixed On the upper surface of the bottom disk of the rotor shaft 4; the first drive magnet 6 and the second drive magnet 7 are cuboids, which are permanent magnets with opposite polarities after magnetization. The first drive magnet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com