Photo-curing adhesive for oral cavities and method for preparing photo-curing adhesive

An adhesive and light-curing technology, applied in dental preparations, pharmaceutical formulas, dental prostheses, etc., can solve the problems of patient allergies and adverse effects, achieve bond strength, reduce light-curing time, and have a good market prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

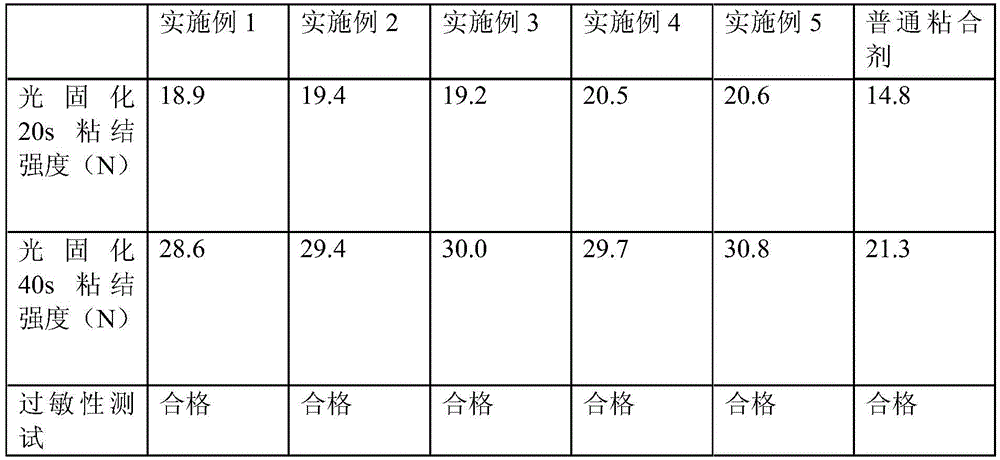

Examples

Embodiment 1

[0017] A light-curing oral adhesive, consisting of the following components by mass: 67 parts of epoxy resin, 12 parts of polyisobutylene, 4 parts of tributyl citrate, 2 parts of p-toluenesulfonic acid, 16 parts of glycerin, carapace 1 part of trilaurylamine, 4 parts of trilaurylamine, 3 parts of hydroxyethyl methacrylate, 2 parts of tartaric acid, 3 parts of N,N-dimethyl-p-aniline.

[0018] Preparation:

[0019] (1) According to the above mass parts, epoxy resin, polyisobutylene, p-toluenesulfonic acid, glycerin, chitin, hydroxyethyl methacrylate, tartaric acid and N,N-dimethyl-p-aniline are placed in a mixing mixer, Mix evenly at a temperature of 160°C to obtain Mixture 1, wherein the pressure in the mixing mixer is 0.3MPa;

[0020] (2) Add trilaurylamine and tributyl citrate to the mixture 1 obtained in step (1), and sonicate at 60° C. for 10 minutes to obtain mixture 2;

[0021] (3) Cool the mixed material 2 obtained in step (2) and put it in a vacuum oven for vacuuming ...

Embodiment 2

[0023] A light-curing oral adhesive, consisting of the following components by mass: 78 parts of epoxy resin, 19 parts of polyisobutylene, 15 parts of tributyl citrate, 13 parts of p-toluenesulfonic acid, 37 parts of glycerin, carapace 7 parts of sodium, 17 parts of trilaurylamine, 12 parts of hydroxyethyl methacrylate, 9 parts of tartaric acid, and 10 parts of N,N-dimethyl-p-aniline.

[0024] Preparation:

[0025] (1) According to the above mass parts, epoxy resin, polyisobutylene, p-toluenesulfonic acid, glycerin, chitin, hydroxyethyl methacrylate, tartaric acid and N,N-dimethyl-p-aniline are placed in a mixing mixer, Mix evenly at a temperature of 200°C to obtain Mixture 1, wherein the pressure in the mixing mixer is 0.6MPa;

[0026] (2) Add trilaurylamine and tributyl citrate to the mixture 1 obtained in step (1), and ultrasonicate for 15 minutes at 85° C. to obtain mixture 2;

[0027] (3) Cool the mixed material 2 obtained in step (2) and put it in a vacuum oven for vac...

Embodiment 3

[0029] A light-curing oral adhesive, consisting of the following components by mass: 69 parts of epoxy resin, 13 parts of polyisobutylene, 6 parts of tributyl citrate, 4 parts of p-toluenesulfonic acid, 19 parts of glycerin, carapace 2 parts of trilaurylamine, 6 parts of trilaurylamine, 5 parts of hydroxyethyl methacrylate, 3 parts of tartaric acid, and 4 parts of N,N-dimethyl-p-aniline.

[0030] Preparation:

[0031] (1) According to the above mass parts, epoxy resin, polyisobutylene, p-toluenesulfonic acid, glycerin, chitin, hydroxyethyl methacrylate, tartaric acid and N,N-dimethyl-p-aniline are placed in a mixing mixer, Mix evenly at a temperature of 170°C to obtain Mixture 1, wherein the pressure in the mixing mixer is 0.35MPa;

[0032] (2) Add trilaurylamine and tributyl citrate to the mixture 1 obtained in step (1), and sonicate at 65° C. for 12 minutes to obtain mixture 2;

[0033] (3) Cool the mixed material 2 obtained in step (2) and put it in a vacuum oven for vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com