Square billet washing, blow-drying and loosening machine

A motive, washing and blowing technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of harsh working environment, high working intensity, waste of water resources, etc. Easy to maintain and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

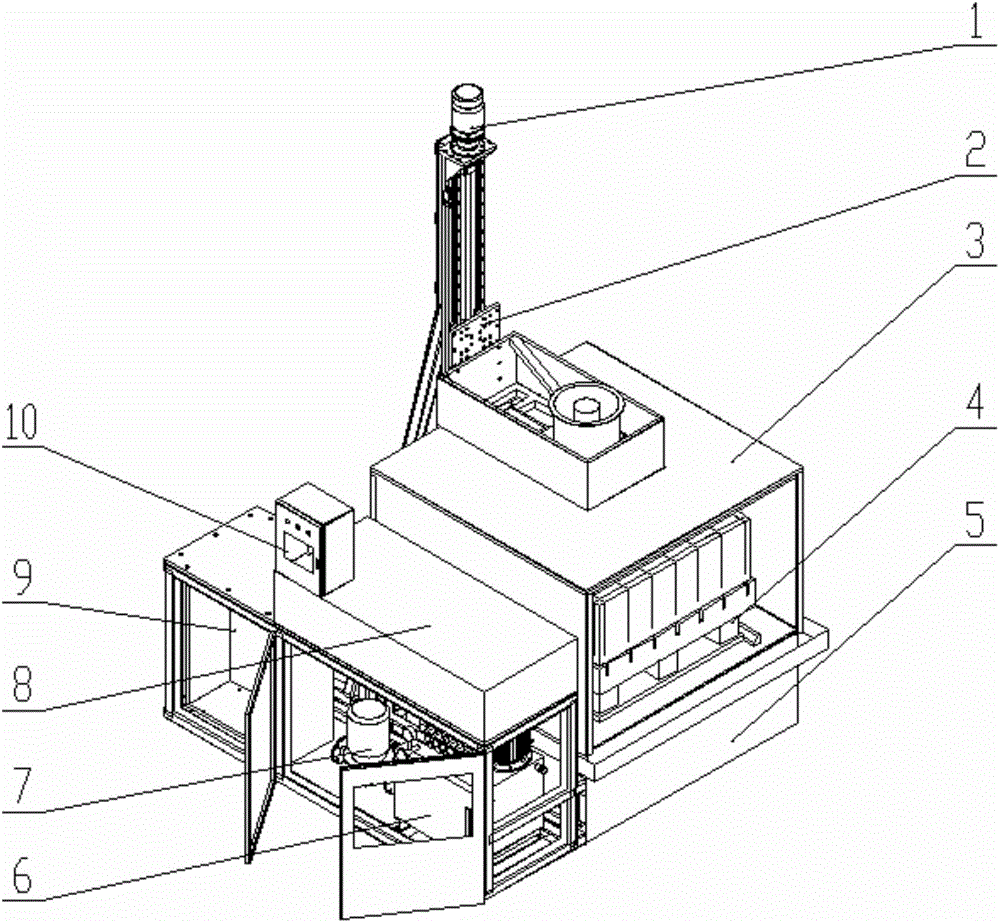

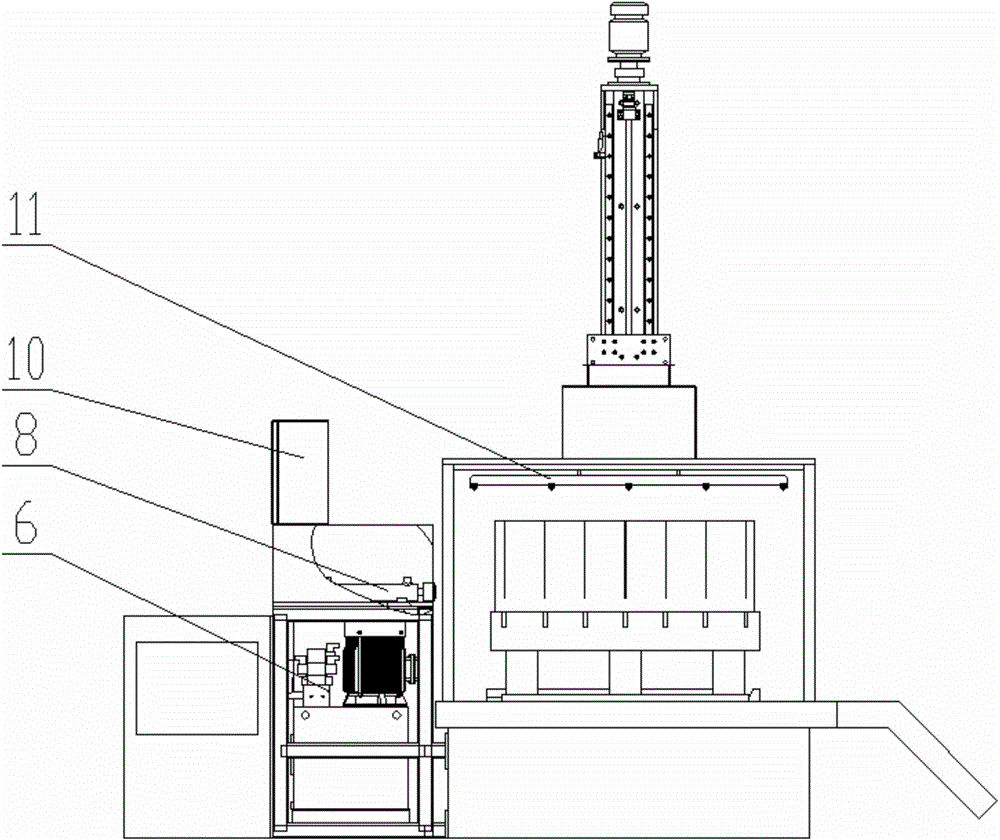

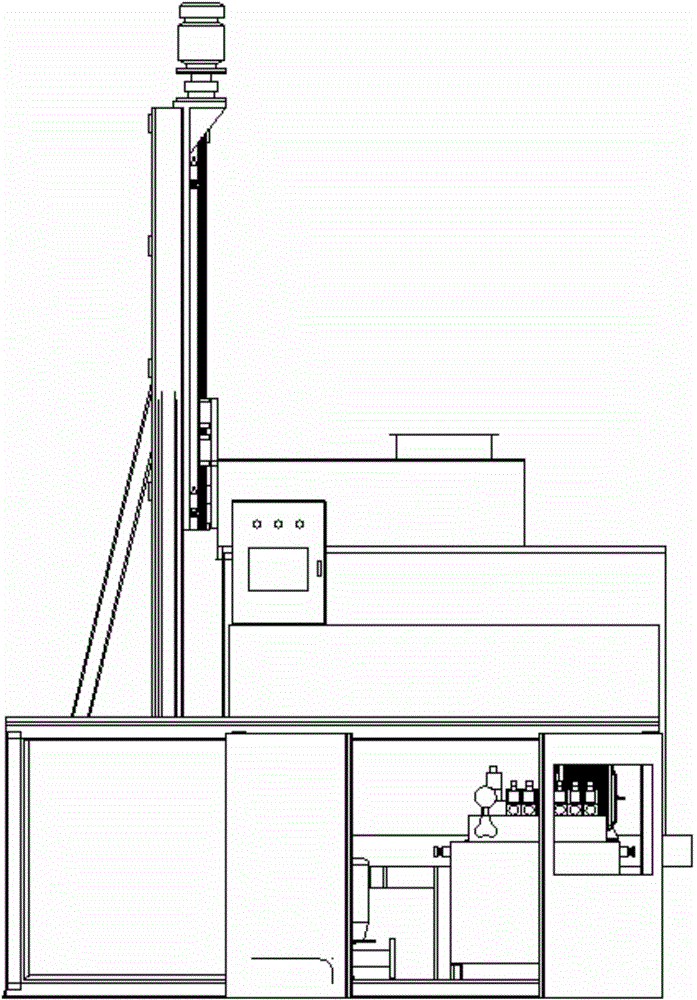

[0016] This embodiment provides a square washing and blowing loosening machine, which is characterized in that: the square washing and loosening machine includes a lifting motor 1, a linear slide table 2, a moving cover 3, a silicon billet 4, a base 5, a hydraulic Station 6, water pump 7, electrical box 9, oil cylinder 8, control box 10, rotatable water and air nozzle 11;

[0017] Among them: the lifting motor 1 is connected to the top of the linear sliding table 2 by a flange, and the linear sliding table 2 has a sliding table that can move along the slide rail. The sliding table and the moving cover 3 are connected by bolts to move up and down, and the moving cover 3 Move down to cover the workpiece silicon billet 4 for washing and drying; open up to load, loosen and remove the workpiece; The hydraulic station 6, the water pump 7, and the electrical box 9 on the profile frame of the workbench; the oil cylinder 8 and the control box 10 are arranged on the workbench, and they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com