Electrical control system of double housing planer

An electric control system and planer technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of high equipment downtime rate, frequent failures, large operating noise, etc., and achieve simple structure and wiring. The effect of faults and simple lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

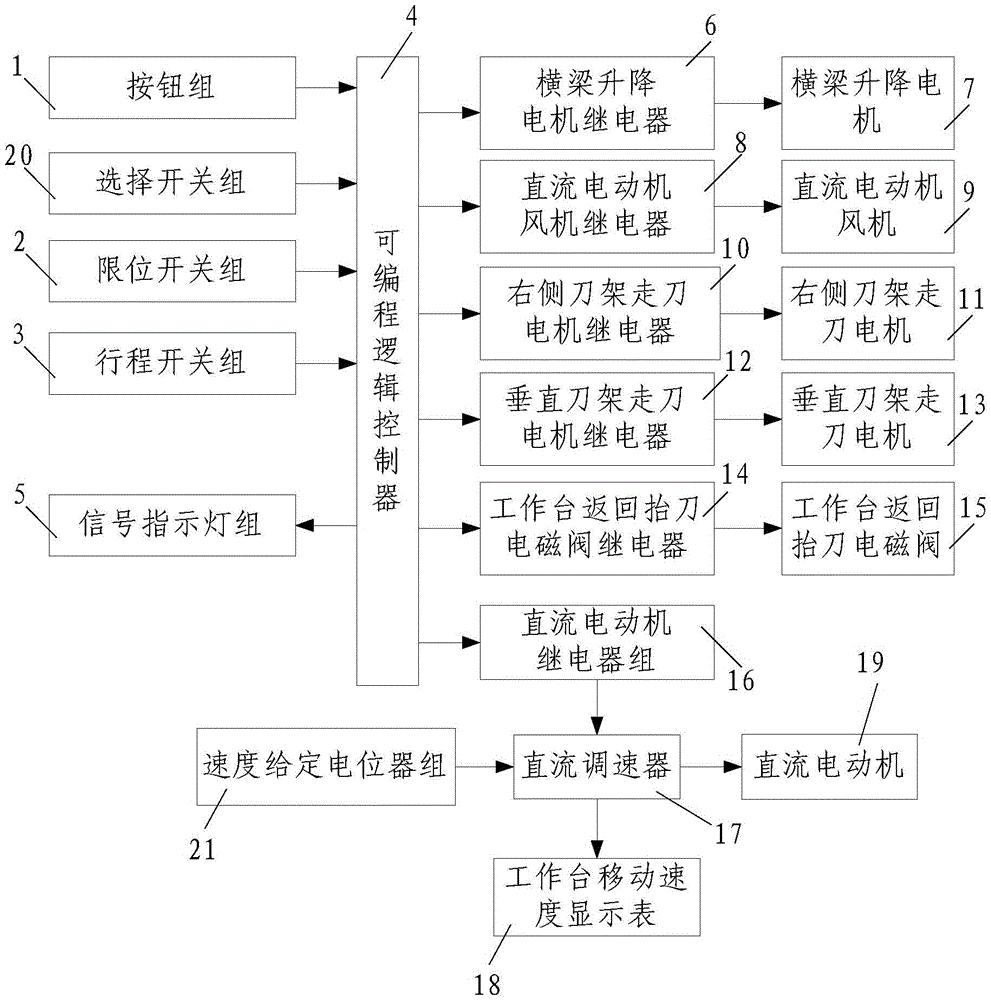

[0033] like figure 1 As shown, the present invention includes a programmable logic controller 4 and a DC governor 17 for speed regulation of the DC motor 19 that drives the planer workbench to move, and the input terminal of the DC governor 17 is connected with a speed feeder. Fixed potentiometer group 21, the output terminal of described DC governor 17 is connected with the workbench moving speed indicator 18 that is arranged on the suspension operation box; The armature circuit and the excitation circuit of the gearbox 17; the input interface of the programmable logic controller 4 is connected with the button group 1 and the selection switch group 20 arranged on the suspension operation box, which are used to adjust the workbench in the planer , the limit switch group 2 for limiting the movement of the crossbeam, the right tool rest and the vertical tool rest, and the travel switch group 3 for detecting the multi-speed section and the reversing stroke of the gantry planer wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com