Alkali-free glass and application of alkali-free glass to substrates of flat-panel displays

An alkali-free glass and strain point technology, applied in the field of glass manufacturing, can solve problems such as the deterioration of glass surface quality and poor chemical resistance of glass substrates, achieve high strain point and Young's modulus, realize light and thin wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

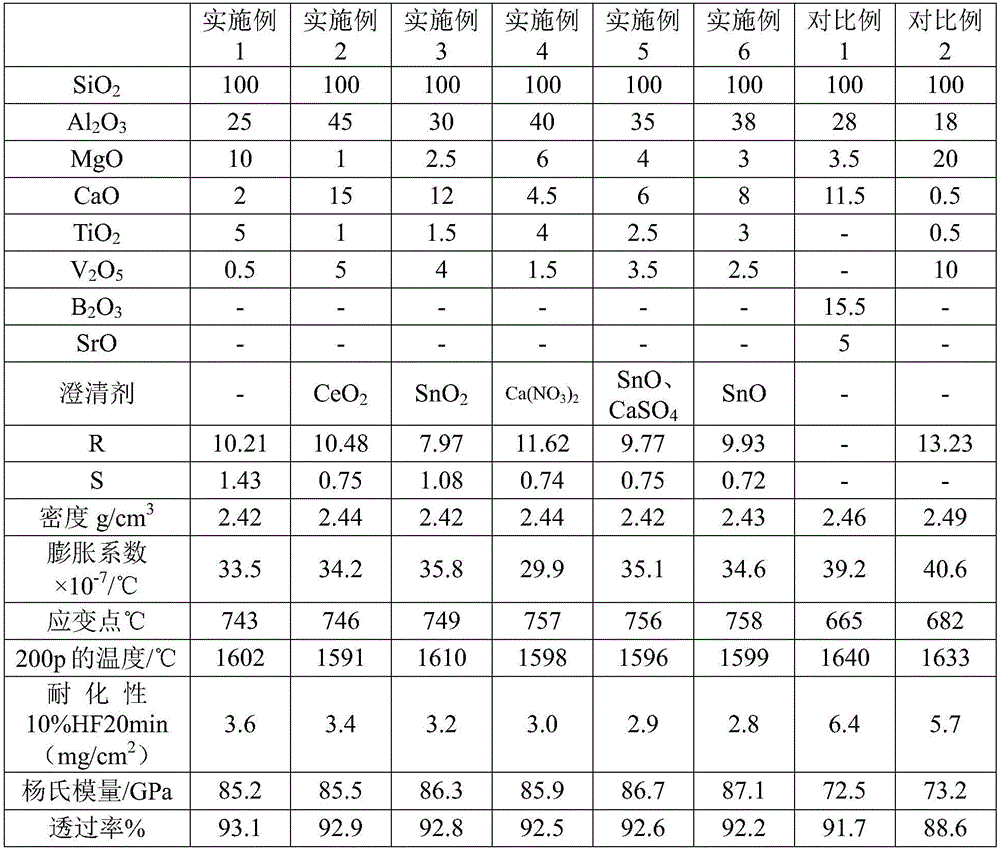

[0036] Table 1 shows the components and contents of the alkali-free glass in Examples 1-6 and Comparative Examples 1-2.

[0037] The alkali-free glass in each embodiment is prepared according to the following steps: each component is weighed according to the weight percentage and fully mixed, and kept in a platinum-rhodium crucible at 1650° C. for 20 hours, stirring with a platinum rod to remove air bubbles, and Clarify and homogenize the glass liquid. Then, pour the molten glass into a stainless steel mold, anneal at 800°C, and test various physical and chemical properties after cooling down to room temperature. Among them, the coefficient of linear thermal expansion is measured by a horizontal dilatometer, and the coefficient of linear thermal expansion (CTE) in the range of 50-350 °C is measured by ×10 -7 / °C; the strain point is measured by a bending beam viscometer, and the unit is expressed in °C; the density is measured by the Archimedes method, and the unit is g / cm 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com