Preparation method of non-through fractured rock mass test sample based on 3D printing technology

A fractured rock mass and 3D printing technology, applied in the field of rock mechanics, can solve the problems of not being able to prepare rock-like materials, destroy the fracture structure, affect the size and distribution of fractures, etc., and achieve convenient and quick demoulding, wide application range and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

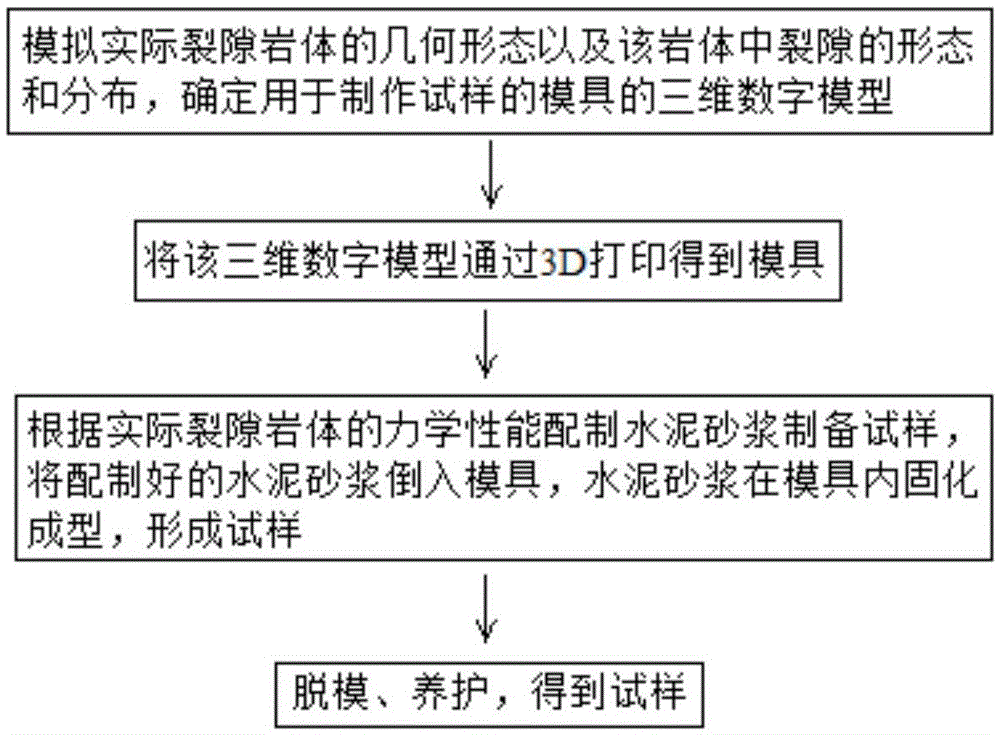

[0027] Such as figure 1 , a method for preparing a non-perforated fractured rock mass sample based on 3D printing technology of the present invention, comprising the following steps:

[0028] (1) Simulate the geometric shape of the actual fractured rock mass and the shape and distribution of the cracks in the rock mass, including the geometric size of the actual fractured rock mass, the size of the cracks, the spatial form, the distribution of the quantity set, etc., and determine the samples for making samples 3D digital model of the mold;

[0029] (2) Obtain the mold by 3D printing the three-dimensional digital model;

[0030] (3) Simulate the mechanical properties of the actual cracked rock mass to prepare cement mortar to prepare samples, pour the prepared cement mortar into the mold, and the cement mortar will solidify and form in the mold to form a sample; you can wait for the cement mortar to solidify and form by itself , it is also possible to maintain the mold loade...

Embodiment

[0039] Taking the preparation of non-perforated fractured rock mass samples at the river bed dam foundation of a certain hydropower station as an example, the method for preparing non-perforated fractured rock mass samples based on 3D printing technology of the present invention includes the following steps:

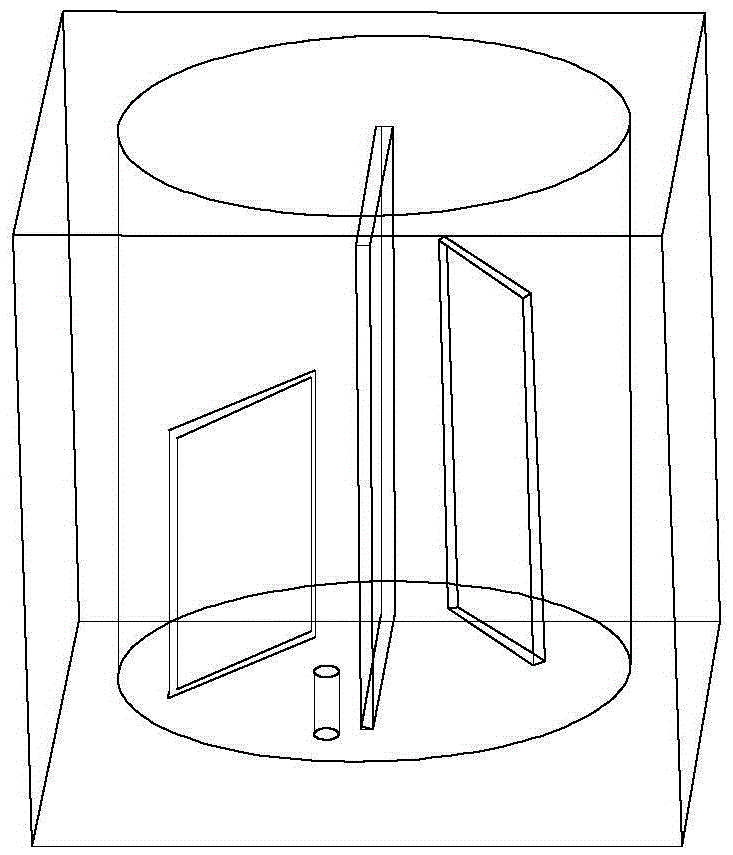

[0040] (1) By consulting the geological report data at the river bed dam foundation of the hydropower station, determine the development status of the cracks in the non-through cracked rock mass, including the length, width, spatial form, quantity, and distribution of the cracks, which are determined according to the similarity relationship The volume of the rock mass sample, the size of the crack, the spatial form, the quantity and the distribution, make a three-dimensional digital model corresponding to the sample, such as figure 2 .

[0041] (2) Input the three-dimensional digital model of the mold into the 3D printer, and the nozzle of the printer is filled with cob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com