Mesh cloth alkali resistant curing box

A technology of curing box and mesh cloth, applied in the field of construction, can solve the problems of difficult operation, difficult coordination, low detection efficiency and accuracy rate of test personnel, and achieve the effects of high control precision, high work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

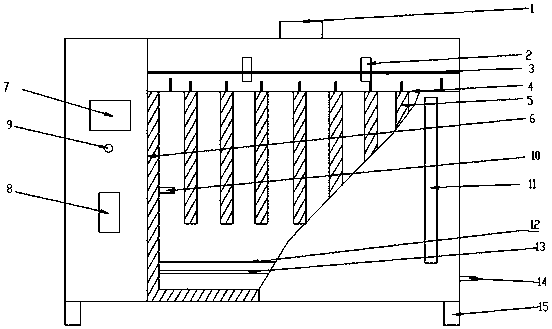

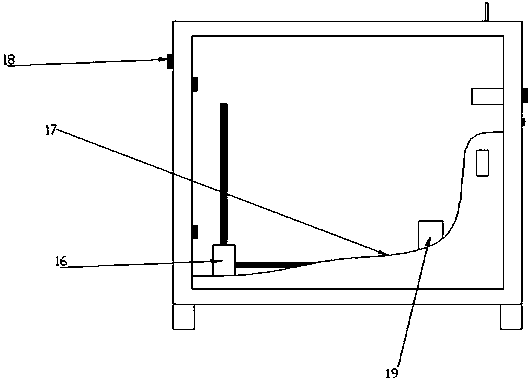

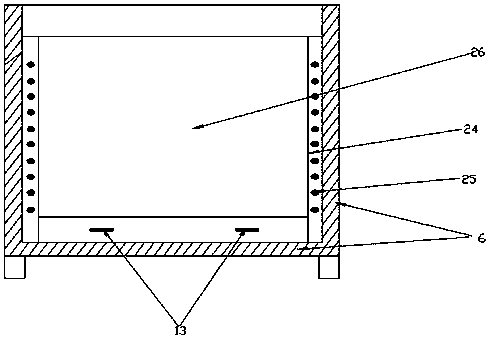

[0018] Below in conjunction with accompanying drawing, the present invention will be further described,

[0019] Such as Figure 1 to Figure 4 As shown, the present invention provides a mesh cloth alkali-resistant curing box, the structure of which includes a box cover handle 1, a box cover hasp 2 for fixing, and an inner box cover sealing strip 3. A number of sample partitions 4 with square holes are arranged in the box, and a lower porous partition 12 is provided correspondingly below. Removable sample cages 5 are respectively arranged in the square holes. The sample cage 5 is a multi-layer drawer-shaped rectangular parallelepiped structure with handles. One side is provided with a hinged cage door. Through the sample cage hinges 22 on both sides and the test The sample cage hasp 21 controls the switch, and the sample cage handle 20 is arranged above;

[0020] The sample cage 5 is equipped with multi-layer sample cage partitions and rails 23; the bottom of the box is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com