Temperature-based topological optimization method for comparing manufacturability constraint of connectivity

A topology optimization and connectivity technology, used in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as increasing costs, inability to remove support materials, and increasing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

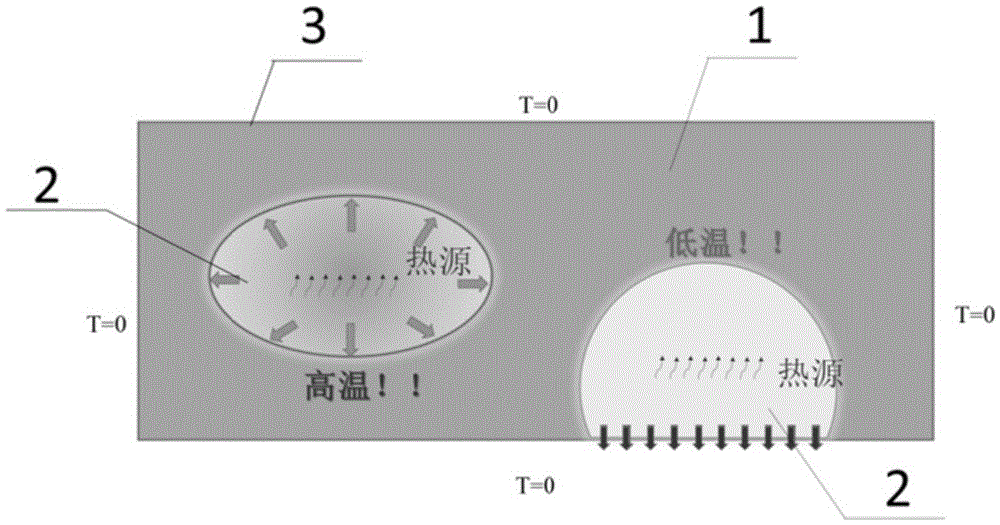

[0089] refer to Figure 4~5 , taking a three-dimensional torsion cantilever cylinder as an example to illustrate the present invention. The size of the three-dimensional cantilever cylinder is 60mm in length and 20mm in diameter in section. The left side of the cantilever beam is fully fixed, and the right side is subjected to torque. The cantilever beam structure is designed so that its stiffness is the largest, the volume ratio is 40%, and the two ends are unavailable finite element models. The specific steps of the method are as follows:

[0090] (a) Establish CAD and CAE models of the initial structure, and apply boundary conditions such as loads and constraints. The load on the model is the section torque at the right end, and the boundary condition is fully fixed on the left side.

[0091] (b) Determine the possible finite element model of the structure as well as the non-finite element model. The first layer of elements at the left and right ends of the model is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com