Iron and steel enterprise oxygen scheduling optimization system and iron and steel enterprise oxygen scheduling optimization method

A technology for optimizing scheduling and scheduling schemes, applied in manufacturing computing systems, instruments, data processing applications, etc., to achieve the effect of improving the level of scheduling personnel, improving the level and response speed, and reducing the frequency of equipment adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

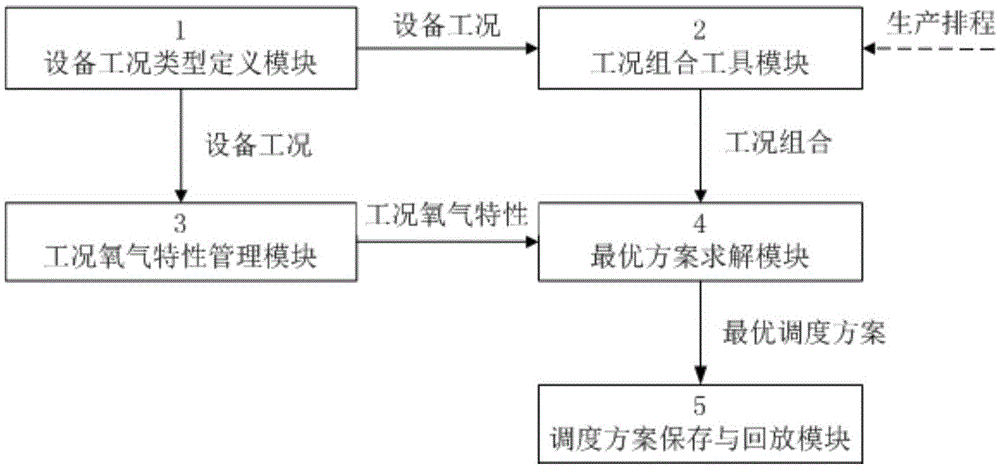

[0027] Such as figure 1 As shown, an oxygen system optimization scheduling method based on comprehensive benefit analysis and a system technical solution of the present invention include equipment working condition type definition module 1, working condition oxygen characteristic management module 2, working condition combination tool module 3, optimal Scheme solving module 4, scheduling scheme saving and playback module 5 and other five modules, the relationship between modules: equipment working condition type definition module 1 respectively outputs equipment working conditions to working condition oxygen characteristic management module 2, working condition combination tool module 3 The working condition combination tool module 3 outputs the oxygen characteristics of the working condition to the optimal solution solution module 4; the optimal solution solution module 4 outputs the optimal solution to the scheduling solution storage and playback module 5 for use and storage....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com