Bearing-free permanent magnetic synchronous generator

A permanent magnet synchronous and generator technology, applied in synchronous machines, synchronous machine parts, magnetic circuits, etc., can solve the problems of reducing dynamic performance, increasing costs, and difficulty in generators, reducing mechanical noise and improving reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

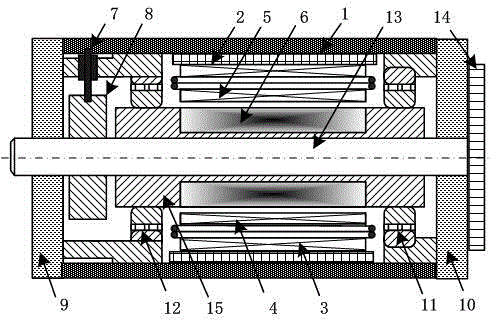

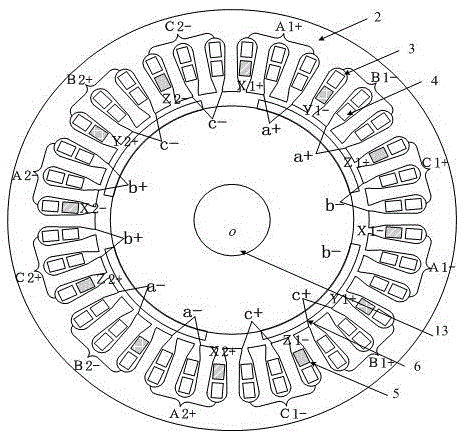

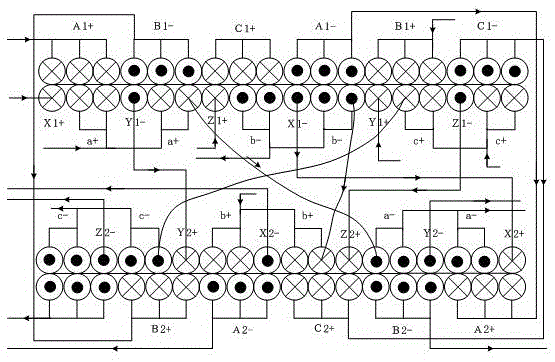

[0021] see figure 1 , the present invention comprises casing 1, stator core 2, permanent magnet rotor and rotating shaft 13, outermost is casing 1, and the axial left end of casing 1 is fixed left end cap 9, and axial right end is fixed right end cap 10. A rotating shaft 13 is installed at the center of the casing 1 , and the rotating shaft 13 is coaxially connected with the casing 1 . There is a stator core 2 and a permanent magnet rotor inside the casing 1, the stator core 2 is fixedly connected to the inner wall of the casing 1, the permanent magnet rotor is coaxially sleeved outside the rotating shaft 13, and the stator core 2 is coaxially sleeved outside the permanent magnet rotor, which belongs to the outer stator Inner rotor structure. There is a radial air gap between the stator core 2 and the permanent magnet rotor. The permanent magnet rotor is composed of permanent magnets 6 and fastening connectors 15 , and the permanent magnets 6 are radially magnetized and surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com