Pipe bundle device and method for extracting isolated soybean protein in ultrasonic-assisted manner

A soybean protein isolate and ultrasonic technology, applied in plant protein processing, food ingredients, and textured treatment, can solve the problems of difficult microbial control, decreased extraction rate, long extraction time, etc., and achieve improved color, taste, and extraction rate The effect of improving and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

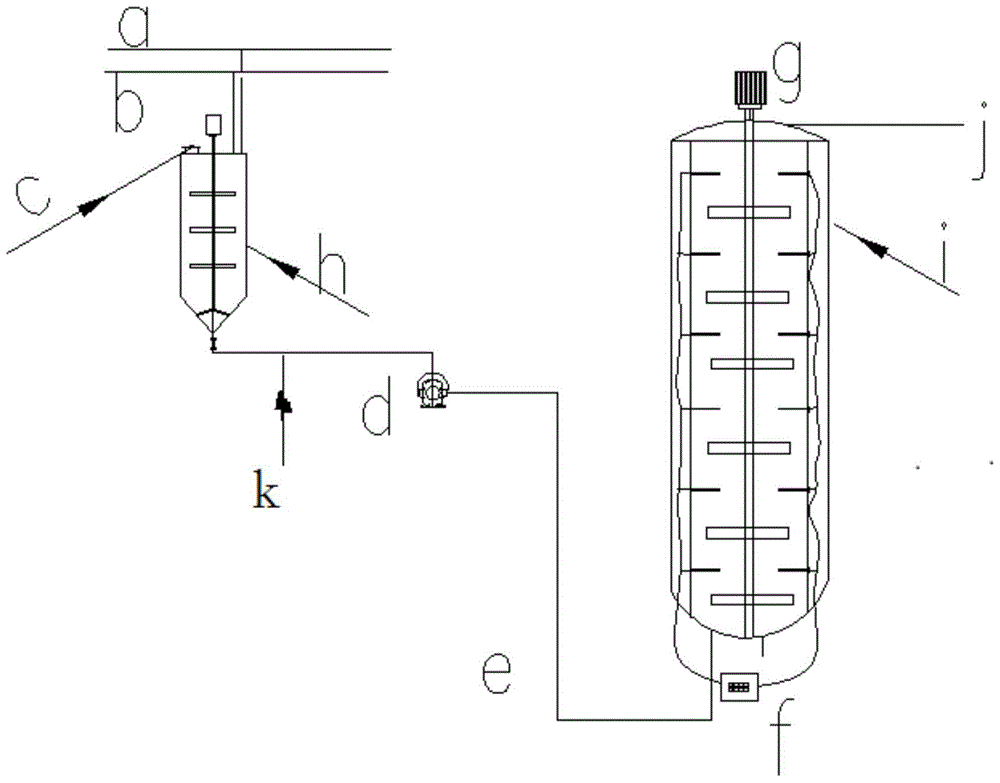

[0028] An ultrasonic-assisted extraction tube bundle device, the extraction tube bundle device includes: soybean meal premixing tank h, wet ultrafine pulverizer d, ultrasonic auxiliary tube bundle i, the upper end of the premixing tank includes alkaline water pipeline a, pure water pipeline b . Soybean meal delivery pipeline c, the lower end of which is connected to the upper end of the wet-process superfine pulverizer through the premixed material delivery pipeline k; the lower end of the wet-process superfine pulverizer is connected to the bottom of the ultrasonic auxiliary tube bundle through the pulverized material delivery pipeline e, and a stirrer is arranged inside the tube bundle g, an ultrasonic generator f is provided outside, and an extract delivery pipeline j is provided. For the above-mentioned extraction tube bundle device, the ultrasonic auxiliary tube bundle is directly 400mm-800mm, preferably 400mm-600mm, wherein the frequency of the ultrasonic generator is 20-...

Embodiment 2

[0032] The method of extracting soybean protein isolate, mixing low-temperature soybean meal and 30% sodium hydroxide light alkali aqueous solution with a pH of 11.0±0.4 in a premixing tank at a mass ratio of 8:1, and continuously discharging after premixing for 25 minutes. The material conveying pipeline is input to the wet ultrafine pulverizer, crushed to 200 mesh, and the pulverized material is conveyed to the ultrasonic auxiliary tube bundle through the pulverized material conveying pipeline, extracted for 20min under the action of the agitator and the ultrasonic generator, at a temperature of 30°C, stirring The speed is 50r / min. After extraction, it enters the horizontal spiral centrifuge to separate the soymilk. The soymilk undergoes acid precipitation and then the horizontal spiral centrifuge to obtain protein solids. The centrifuge adopts continuous processing with a flow rate of 22-25m 3 / H, centrifugal force 2500-3600G; rotating speed, 2500-3200r / min, after adding alk...

Embodiment 3

[0034] The method of extracting soybean protein isolate, mixing low-temperature soybean meal and 30% sodium hydroxide light alkali aqueous solution with a pH of 11.0±0.4 in a premixing tank at a mass ratio of 8:1, and continuously discharging after premixing for 15 minutes. The material conveying pipeline is input to the wet ultrafine pulverizer, crushed to 40 mesh, and the pulverized material is conveyed to the ultrasonic auxiliary tube bundle through the pulverized material conveying pipeline, extracted for 30 minutes under the action of the agitator and the ultrasonic generator, at a temperature of 45°C, stirring The speed is 70r / min. After extraction, it enters the horizontal spiral centrifuge to separate the soymilk. The soymilk undergoes acid precipitation and then the horizontal spiral centrifuge to obtain protein solids. The centrifuge adopts continuous processing with a flow rate of 22-25m 3 / H, centrifugal force 2500-3600G; rotating speed, 2500-3200r / min, after adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com