A kind of synchronous plastic coating production equipment for inner and outer walls of steel pipes

A technology for production equipment, inner and outer walls, applied in the direction of injection devices, etc., can solve the problems of unstable quality, dirty working environment, low production efficiency, etc., to reduce equipment costs and operating costs, improve resource utilization, and production quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

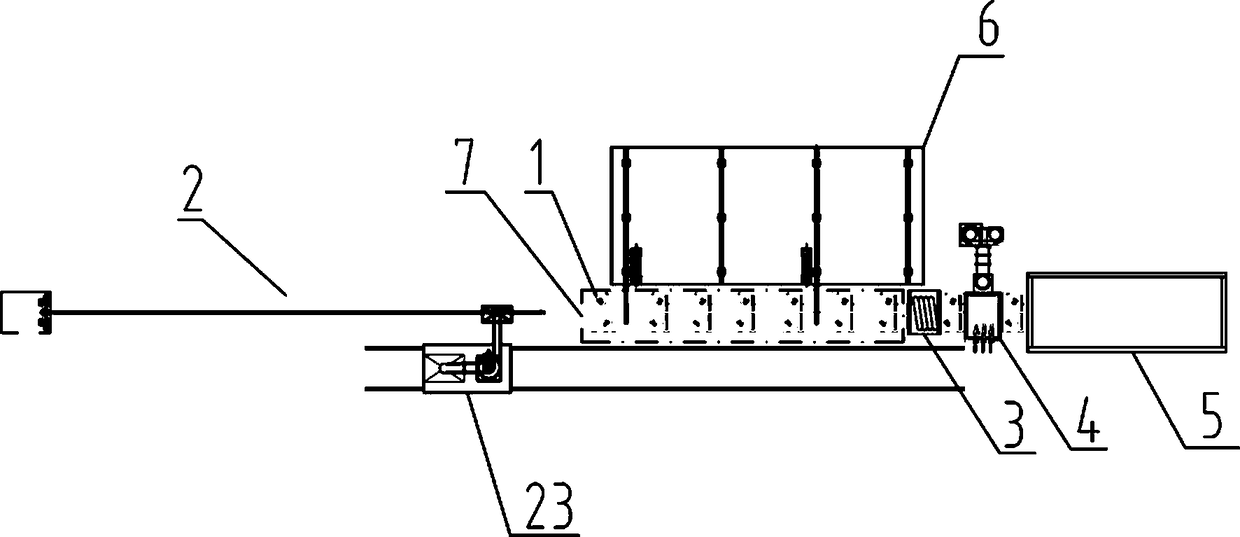

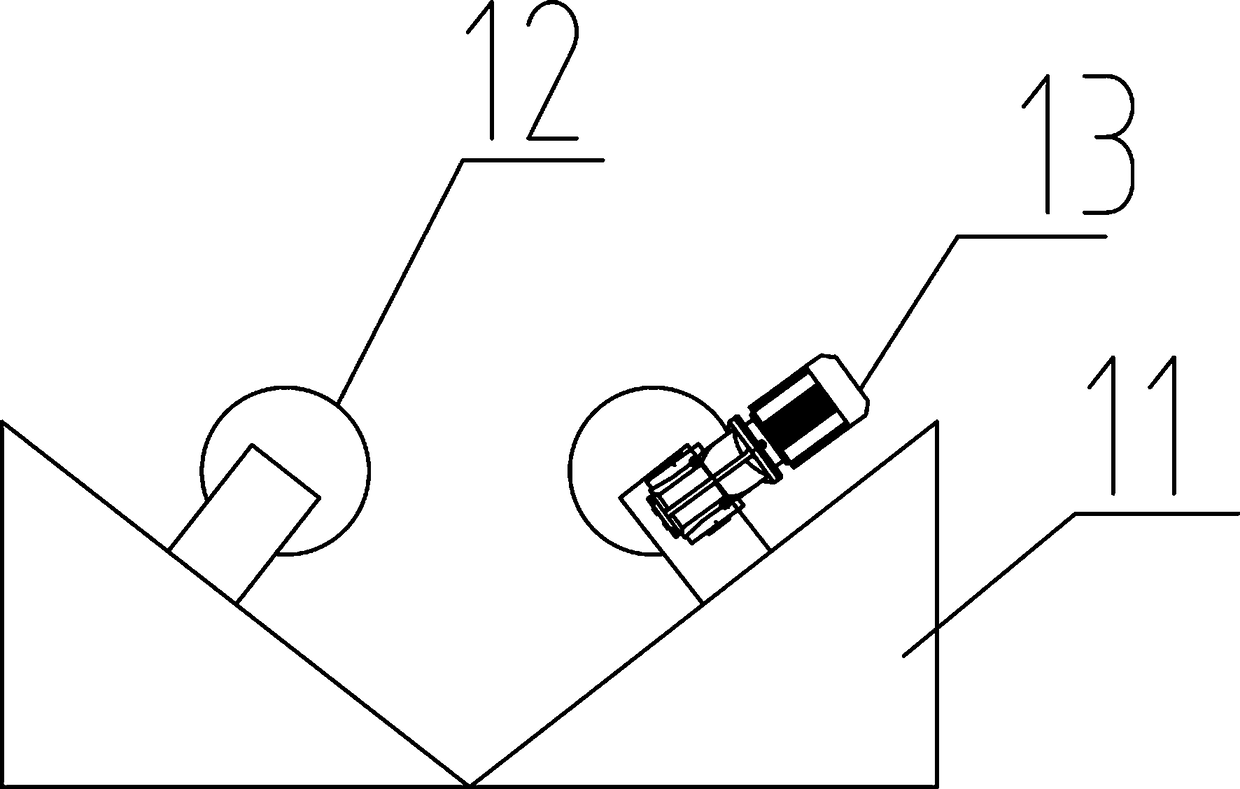

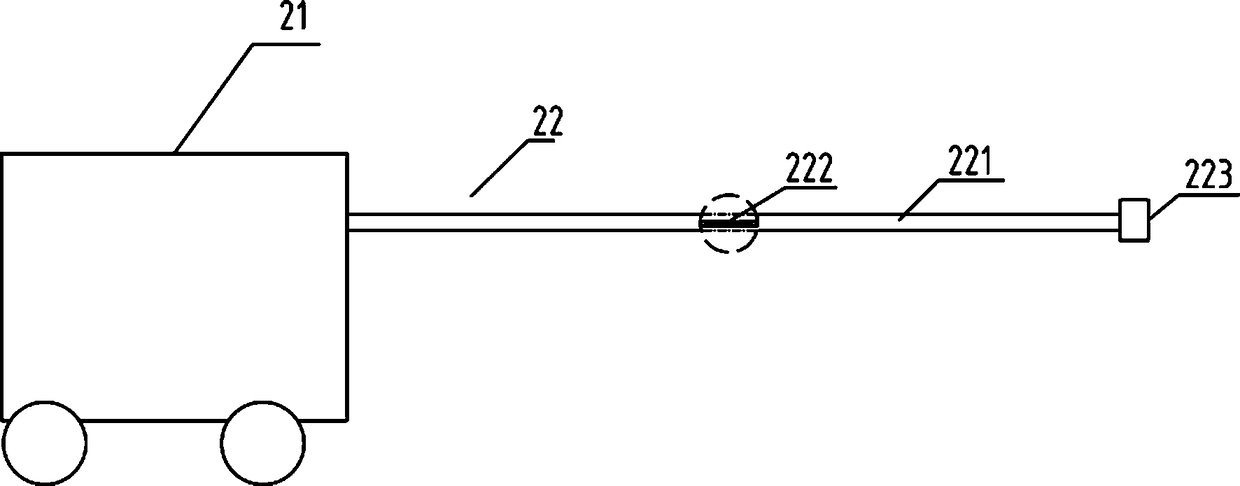

[0032] Such as figure 1 Among them, a synchronous plastic coating production equipment for the inner and outer walls of steel pipes includes a rotary transmission support propulsion component 1, an internal spray system 2, a heating system 3, and an external spray system 4. A plurality of rotary transmission support propulsion components 1 are arranged in series to form a bearing system 7, at least A rotary transmission support propulsion component 1 is arranged between the heating system 3 and the external spray system 4. Preferably, a synchronous plastic coating production equipment for the inner and outer walls of steel pipes also includes a cooling system 5, between the cooling system 5 and the external spray system 4 Be provided with at least one rotary support propulsion part 1, the feeding system 6 is arranged on one side of the carrying system, such as Figure 6 Among them, the feeding system 6 includes a support frame 61 and a rotating arm 62 hinged at one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com