Board drawing forming device and method based on electrorheological fluid

A technology of electrorheological fluid and sheet metal, which is applied in the field of sheet metal deep drawing and forming devices based on electrorheological fluid, and in the field of sheet metal deep drawing and forming devices, which can solve problems such as increased cleaning process, poor force transmission effect, and difficult sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

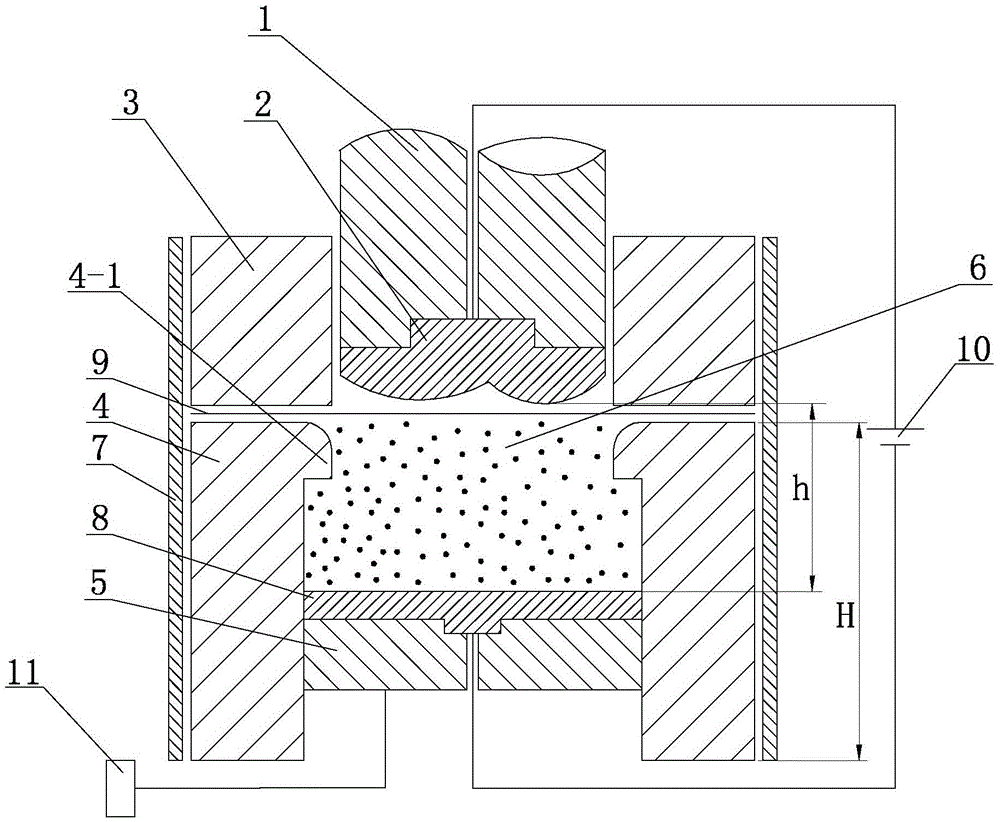

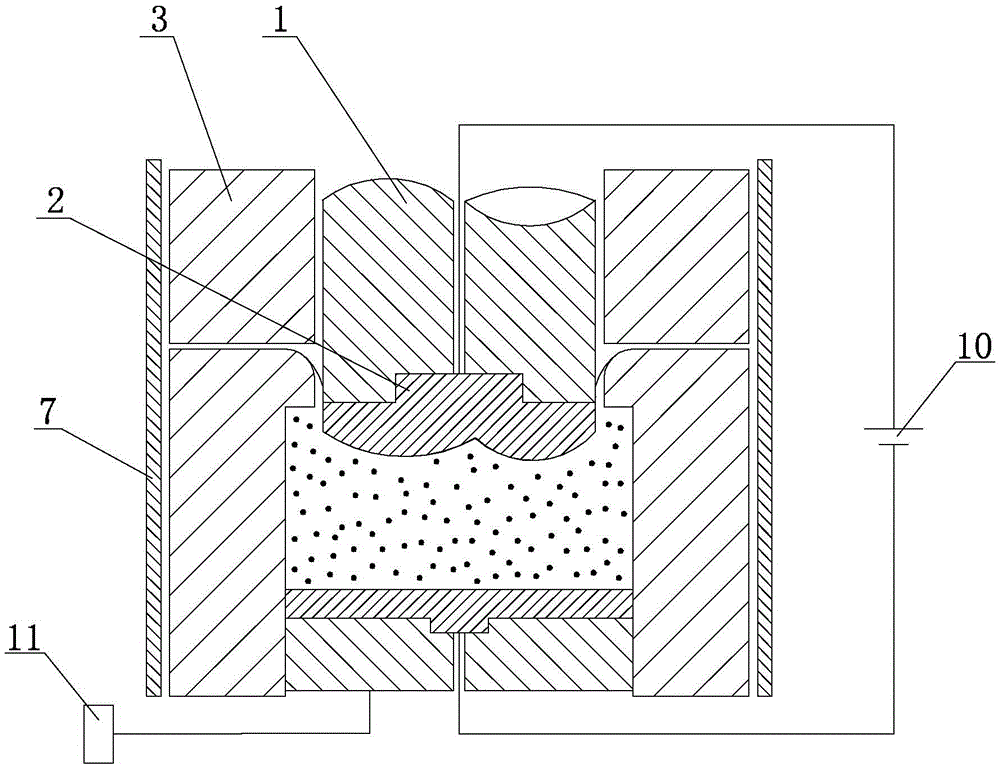

[0031] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes punch seat 1, punch terminal 2, blank holder 3, die 4, plunger 5, insulating layer 7, electrode plate 8, power supply control unit 10 and plunger control unit 11 , the blank holder 3 and the die 4 are set up and down, the punch terminal 2 and the punch seat 1 are arranged in the inner hole of the blank holder 3 from bottom to top, and the plunger 5 and the electrode plate 8 are arranged in the concave from bottom to top. In the inner hole of the mold 4, the concave mold 4 and the electrode plate 8 form a closed liquid chamber cavity 6 for containing the electrorheological fluid, and the punch terminal 2 can pass through the blank holder 3 to drive the sheet material 9 down into the liquid chamber cavity 6, the upper entrance of the die 4 is provided with a flange 4-1, the diameter of the flange 4-1 is smaller than the diameter of the plunger 5, and the insulating layer ...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 Describe this embodiment, the material of the punch base 1, blank holder 3, die 4 and insulating layer 7 of this embodiment is an insulating material, and the insulating material is polytetrafluoroethylene, pottery, plexiglass or epoxy resin; Insulation and high pressure resistance, high strength and hardness, not easy to deform, etc. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the materials of the punch terminal 2 and the electrode plate 8 in this embodiment are metal, oxide, conductive polymer or porous carbon material; they are required to be electrically conductive, have high strength and hardness, and are not easily deformed. Other connections are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com