A laser-arc hybrid welding method for invar die steel

A composite welding and mold steel technology, applied in laser welding equipment, welding medium, welding equipment, etc., can solve the problems of poor weld formation, poor fusion between layers, low production efficiency, etc., and achieve a large total depth-to-width ratio of the weld , Good interlayer fusion effect, small deformation after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

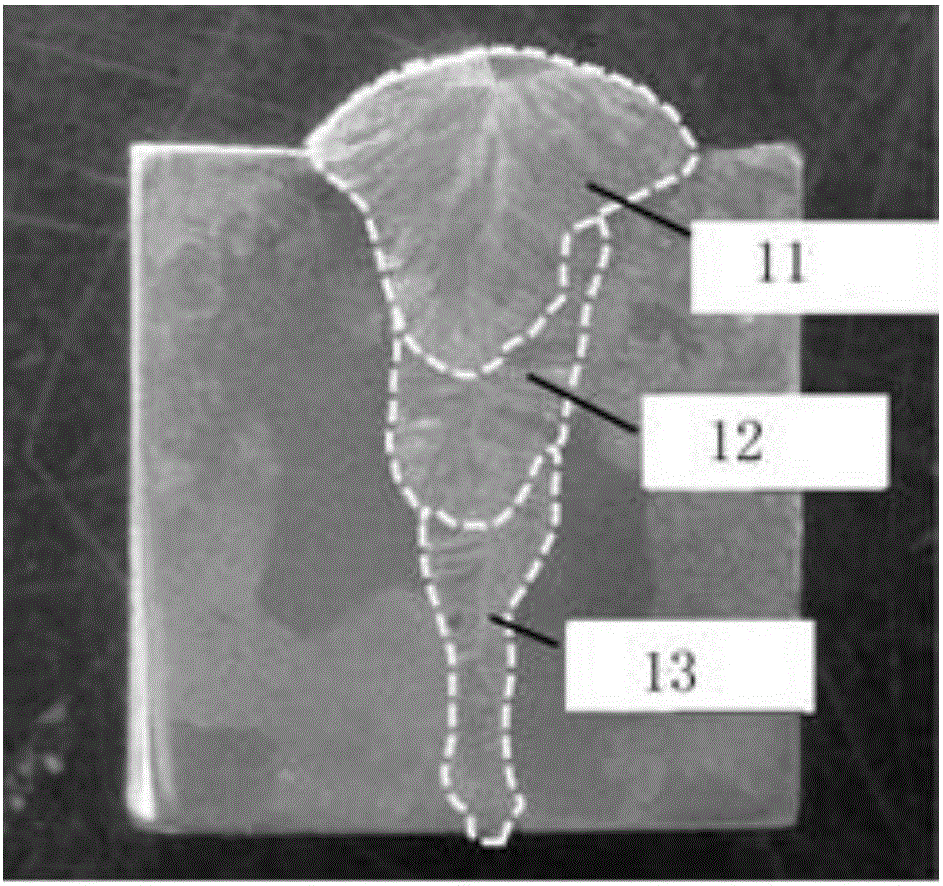

[0030] The welding base material is Invar steel with a Ni content of 35.87%, with a size of 100mm×50mm×19.05mm, a 30° groove, a blunt edge thickness of 6mm, and a spacing of 0.8mm; the welding wire is Invar M93, with a Ni content of 35.87%, and a diameter of 1.2mm ; 99.9% Ar atmosphere flow rate is 15L / min; welding equipment is KUKA robot KR30HA, TPS-5000 Fronius welding machine, IPG YLS-6000 fiber laser; before welding, finely grind the vicinity of the groove to remove residual residue on the surface of the sample Rust and other impurities, use acetone to wipe and clean the sample to remove residual oil to ensure that the surface of the sample is clean; then teach the welding trajectory and set the parameters. The specific parameters are as follows:

[0031] The first layer (first layer 13): straight line trajectory, laser power 5500W, welding current 240A, welding voltage 24.3V, speed 1m / min;

[0032] The second layer (first filling layer 12): straight track, laser power 200...

Embodiment 2

[0036] The welding base material is Invar steel with a Ni content of 35.87%, with a size of 100mm×50mm×19.05mm, a 30° groove, a blunt edge thickness of 6mm, and a spacing of 0.8mm; the welding wire is Invar M93, with a Ni content of 35.87%, and a diameter of 1.2mm ; 99.9% Ar atmosphere flow rate is 15L / min; welding equipment is KUKA robot KR30HA, TPS-5000 Fronius welding machine, IPG YLS-6000 fiber laser; before welding, finely grind the vicinity of the groove to remove residual residue on the surface of the sample For impurities such as rust, use acetone to wipe and clean the sample to remove residual oil to ensure that the surface of the sample is clean; then teach the welding trajectory and set the parameters. The specific parameters are as follows:

[0037] The first layer (second layer 23): laser power 5500W, welding current 240A, welding voltage 24.3V, speed 1m / min;

[0038] The second layer (second filling layer 22): laser power 2400W, welding current 250A, welding volt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com