Foam concrete preparation system and foam concrete preparation method

A foam concrete and preparation system technology, which is applied to clay preparation devices, chemical instruments and methods, ceramic products, etc., can solve the problem of large difference in cell size, defoaming and defoaming unevenness, affecting the strength and properties of foam concrete, etc. problems, to achieve the effect of improved density stability, uniform cell distribution, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

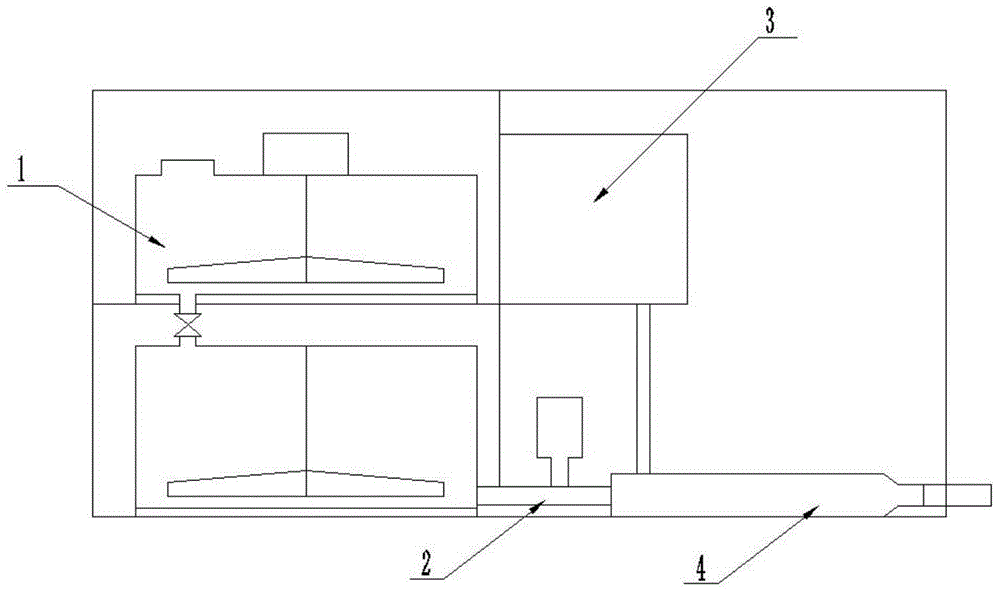

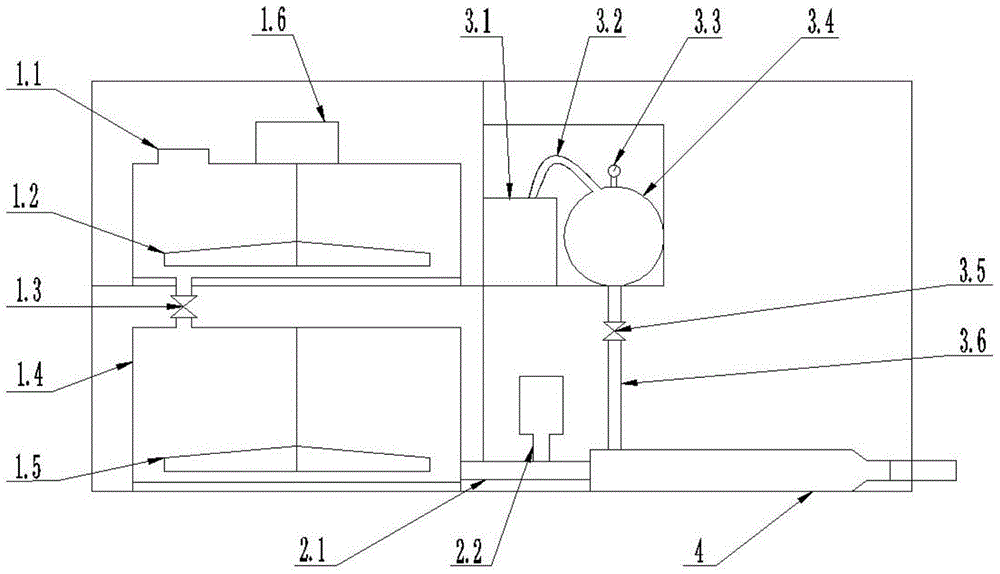

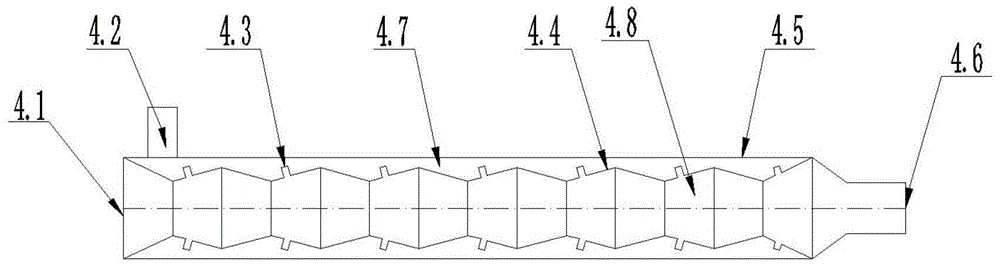

[0019] Such as figure 1 and figure 2 A kind of foam concrete preparation system shown, comprises cement slurry mixing device 1, cement slurry conveying device 2, high-pressure air conveying device 3 and foamed concrete generating device 4, and one end of foamed concrete generating device 4 is provided with slurry inlet 4.1 and inlet The air port 4.2, the other end of the foam concrete generating device 4 is provided with a finished product output port 4.6; the cement slurry mixing device 1 communicates with the slurry inlet 4.1 of the foam concrete generating device 4 through the cement slurry conveying device 2, and the outlet of the high-pressure air conveying device 3 It communicates with the air inlet 4.2 of the foam concrete generator 4.

[0020] In the present invention, if image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com