Multifunctional recombination machine

A compound machine and multi-functional technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of production efficiency discount, product scrap rate increase, film product size, shape and appearance, etc., to ensure good products efficiency and efficiency, improve quality, and avoid bad problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

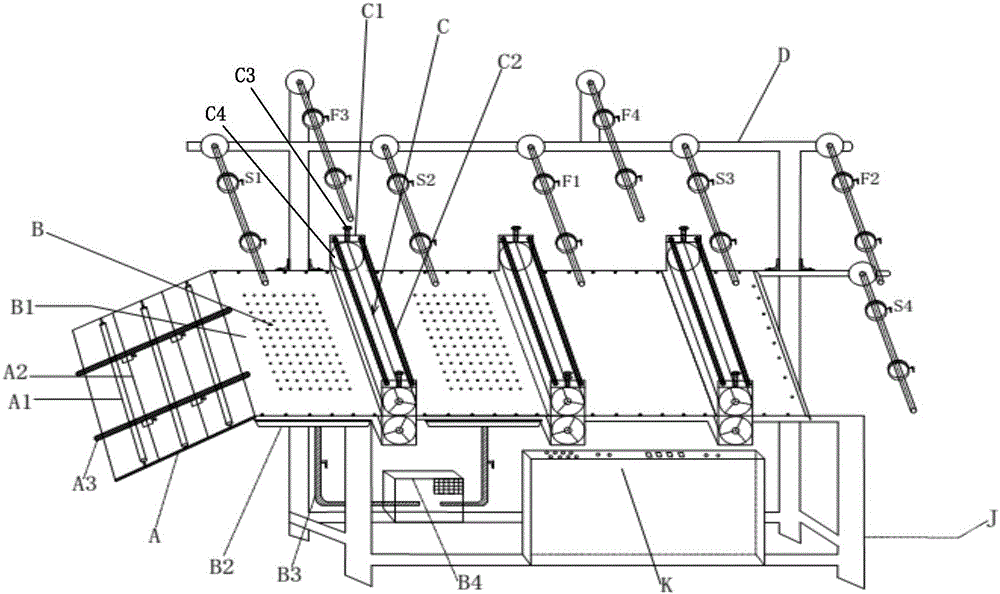

[0020] like figure 1 As shown, the multifunctional compound machine of the present invention includes: a frame J, an adhesive film feeding frame A arranged at the end of the frame J, a suction device B installed on the surface of the frame J, and the suction The wind device B is arranged next to the film feeding frame A, and a plurality of film compounding devices C installed on the frame J, a material guide bracket D positioned on the frame J, and a material guide bracket installed on the guide frame J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com