One-way transparent low-emissivity glass

A technology of low-emissivity glass and one-way perspective, which is applied in coatings and other directions, can solve the problems of not having one-way perspective, being unable to have both one-way perspective and low-emission, and glass not having low-emission, so as to achieve one-way perspective performance , reduce observation interference, low performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

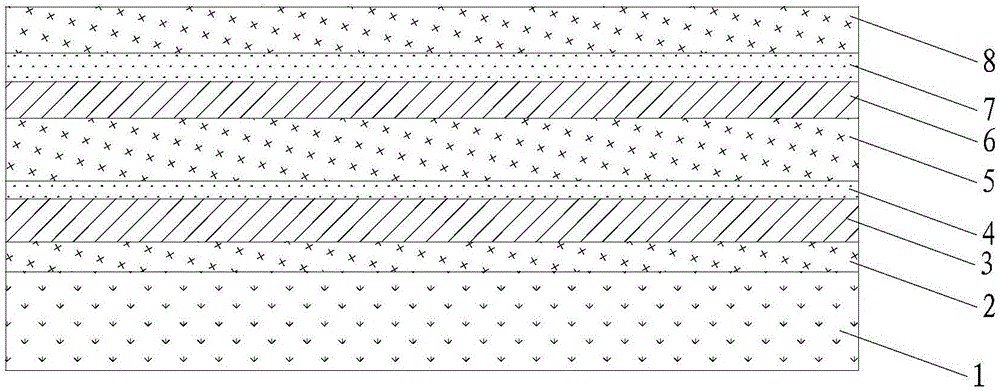

[0028] see figure 1 As shown, the structure of the one-way see-through glass is ordinary white glass substrate / ZnSnO layer / Ag layer / NiCr layer / ZnSnO layer / Ag layer / NiCr layer / Si3N4 layer, and the thickness of each layer is 6mm / 33.5nm / 25.0nm / 7.7nm / 76.2nm / 11.1nm / 1.3nm / 21.4nm. Various layers of films can be sequentially plated on the glass substrate 1 through a magnetron sputtering process, wherein 14 alternating current rotating cathodes and 5 direct current planar cathodes are used for production, a total of 19 cathodes are used for production.

[0029] The performance test of the product is as follows:

[0030] Light reflectance of glass surface (observation object surface): 56%, transmitted color: a*=-3.9, b*=-0.09;

[0031] Light reflectivity of film surface (observation surface): 18%, reflection color: a*=-15, b*=-33;

[0032] Light transmittance of viewing surface: 24%;

[0033] Emissivity: 0.02.

Embodiment 2

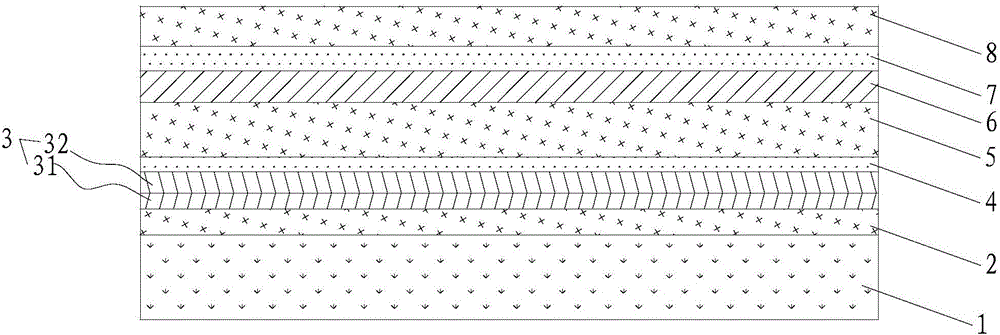

[0035] see figure 2 As shown, the structure of the one-way see-through glass is ordinary white glass substrate / ZnSnO layer / Ag layer / Cu layer / NiCr layer / ZnSnO layer / Ag layer / NiCr layer / Si3N4 layer, wherein the thickness of each layer is 6mm / 17.2 nm / 19.0nm / 6.3nm / 4.4nm / 82.6nm / 15.6nm / 0.7nm / 33.4nm, the Ag layer 31 and Cu layer 32 are stacked to form the first metal reflective layer 3 in the one-way see-through glass. Various layers of films can be sequentially plated on the glass substrate 1 through a magnetron sputtering process, wherein 12 alternating current rotating cathodes and 6 direct current planar cathodes are used for production, a total of 18 cathodes are used for production.

[0036] The performance test of the product is as follows:

[0037] Light reflectance of glass surface (observation object surface): 50%, transmitted color: a*=-0.28, b*=-3.26;

[0038] Light reflectivity of film surface (observation surface): 14%, reflection color: a*=3.5, b*=-13;

[0039] Lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com