Flame-retarding plastic and preparation method thereof

A technology for flame-retardant plastics and raw materials, which is applied in the field of flame-retardant plastics and their preparation, can solve the problems of flame-retardant plastics being easily melted and burned by heat, and achieves the effects of high mechanical strength, improved flame-retardant performance, and good flame-retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A flame-retardant plastic made from the following raw materials in parts by weight: 100 parts of polypropylene, 5 parts of antimony trioxide, 3 parts of magnesium hydroxide, 4 parts of decabromodiphenyl ether, and 3 parts of octabromoether , 5 parts of stearic acid, 8 parts of polypropylene grafted maleic anhydride, 20 parts of mica powder.

[0014] The preparation method of the above-mentioned flame-retardant plastics, the preparation method is:

[0015] a. Put the raw materials of each component into the mixer in proportion and mix them evenly;

[0016] b. Add the mixture obtained in a to a twin-screw extruder, control the temperature of the extruder and the die within the range of 200°C, and the speed of the main engine at 140 rpm, and cool the extrudate to ambient temperature;

[0017] c. Send the cooled extrudate in step b to a granulator to obtain finished flame-retardant plastic granules.

Embodiment 2

[0019] A flame-retardant plastic made from the following raw materials in parts by weight: 100 parts of polypropylene, 13 parts of antimony trioxide, 7 parts of magnesium hydroxide, 4 parts of decabromodiphenyl ether, and 3 parts of octabromoether , 8 parts of stearic acid, 7 parts of polypropylene grafted maleic anhydride, 25 parts of mica powder.

[0020] The preparation method of the above-mentioned flame-retardant plastics, the preparation method is:

[0021] a. Put the raw materials of each component into the mixer in proportion and mix them evenly;

[0022] b. Add the mixture obtained in a to a twin-screw extruder, control the temperature of the extruder and the die within the range of 180°C, and the speed of the main engine at 140 rpm, and cool the extrudate to ambient temperature;

[0023] c. Send the cooled extrudate in step b to a granulator to obtain finished flame-retardant plastic granules.

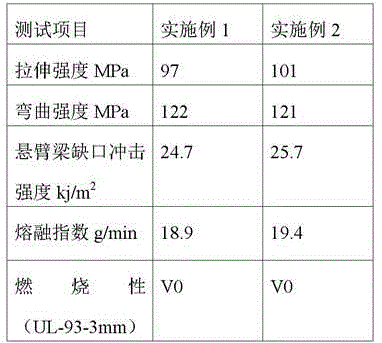

[0024] The flame-retardant plastics obtained from the above examples h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap