Waterproof agent for file cover and preparation method of waterproof agent

A technology of waterproofing agent and archive bag, applied in textile and papermaking, fiber raw material processing, paper coating, etc., can solve the problems of yellowing of archives, moisture absorption of archives, affecting the life of archives, etc., so as to prolong the service life and achieve good waterproof effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Accurately weigh 10g of propolis, 3g of beeswax and 2g of olive oil;

[0027] b. Follow the steps below to prepare a waterproofing agent for portfolios:

[0028] Step 1. Freeze the propolis at -4°C for 24 hours, and crush it into 40-mesh particles;

[0029] Step 2. Put the granules in step 1 into the solution mixed with 100g of absolute ethanol and petroleum ether according to the volume ratio: 1:1, and extract at a temperature of 70°C for 4 hours to obtain the extract, which is plant gum extraction liquid;

[0030] Step 3, add activated carbon to the extract in step 2 and stir for 10 minutes to decolorize to obtain 93ml of decolorized extract;

[0031] Step 4. Take 90ml of the decolorized extract in step 3 and concentrate it to 30ml by rotary evaporation at 50°C to obtain a concentrated solution;

[0032] Step 5: Heat the concentrated liquid in a water bath to 80°C, add beeswax and olive oil, dissolve evenly, and keep the temperature at 55°C to obtain the product...

Embodiment 2

[0034] a. Accurately weigh 12g of poplar gum, 4g of beeswax, and 0.5g of olive oil;

[0035] b. Follow the steps below to prepare a waterproofing agent for portfolios:

[0036] Step 1. Put the poplar gum at -4°C and freeze it for 24 hours, and crush it into 40-mesh particles;

[0037] Step 2. Put the granules in step 1 in the solution mixed with 100g of absolute ethanol and petroleum ether according to the volume ratio: 2:1, and extract at a temperature of 80°C for 2 hours to obtain the extract, which is vegetable gum extraction liquid;

[0038] Step 3, add activated carbon to the extract in step 2 and stir for 10 minutes to decolorize to obtain 94ml of decolorized extract;

[0039] Step 4. Take 90ml of the decolorized extract in step 3 and concentrate it to 30ml by rotary evaporation at 50°C to obtain a concentrated solution;

[0040] Step 5: Heat the concentrated solution in a water bath to 70°C, add beeswax and olive oil, dissolve evenly, and keep the temperature at 60°C...

Embodiment 3

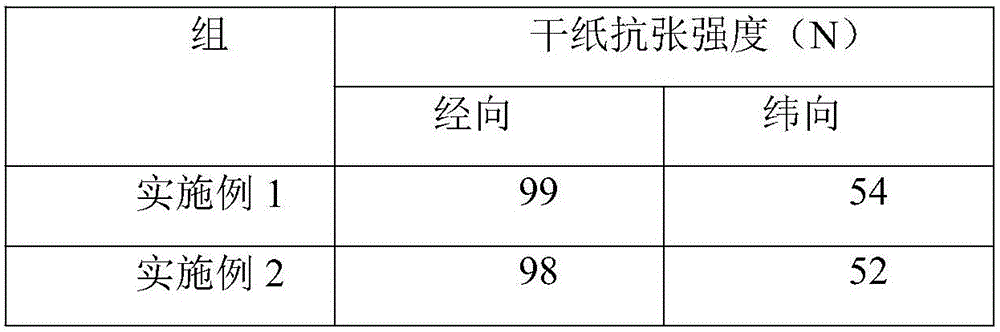

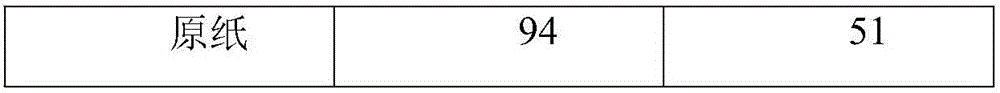

[0041] Embodiment 3 effect detection

[0042] Waterproof test: dip a brush into the heat-preserving waterproofing agent of Example 1 and apply it evenly on the surface of the file bag, and then conduct a water repellency test after it is naturally air-dried. The "effect" is obvious, and the water droplets turn into rolling water droplets one by one, without wetting the paper.

[0043] Water absorption test: according to the national standard GB / T1540-1989, the water absorption of the kraft paper coated with the waterproofing agent of Example 1 and the kraft paper base paper were tested, and the detected values were respectively 26g / m 2 and 190g / m 2 . It shows that the paper coated with the waterproofing agent of Example 1 has remarkable waterproofing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com