Ultra-large type plate shearing machine plate shearing edge curve detection system and method

A detection system and ultra-large technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of heavy manual detection of cutting edges, lack of automatic detection methods, low time-consuming efficiency, etc., to improve data processing Accuracy, high stability, adjustment and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

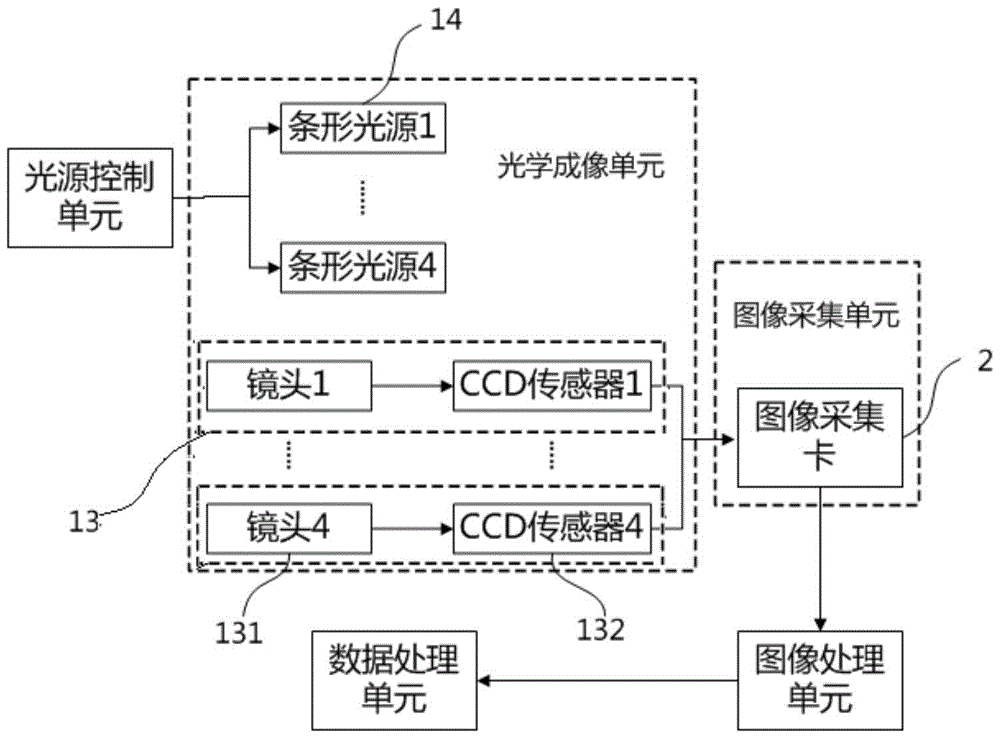

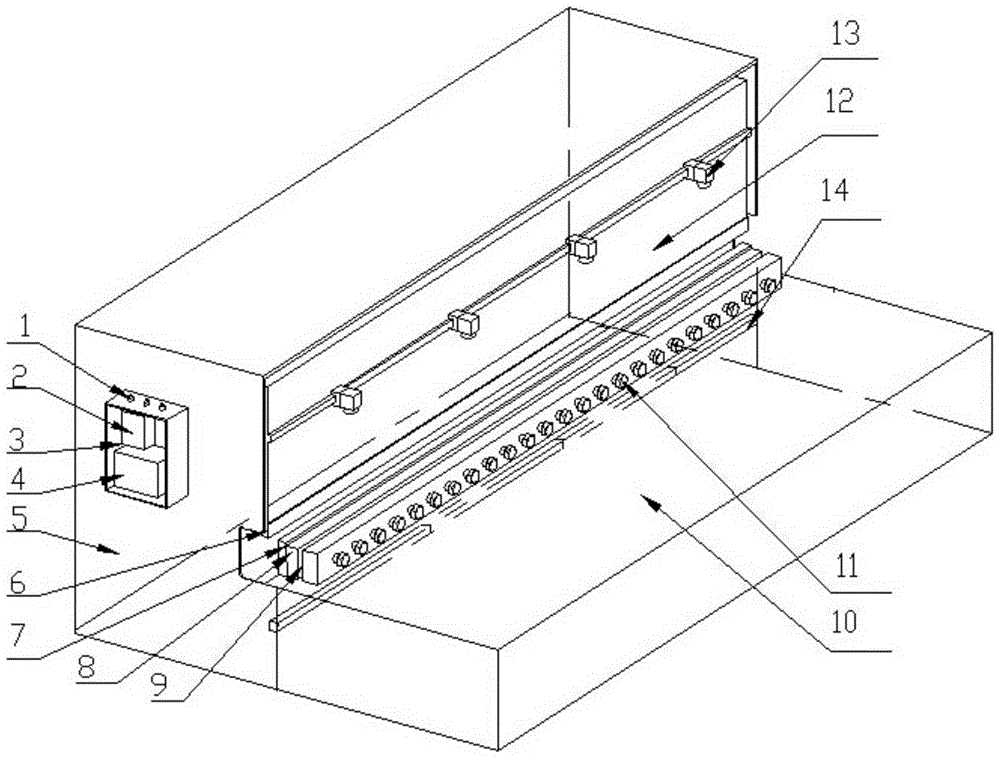

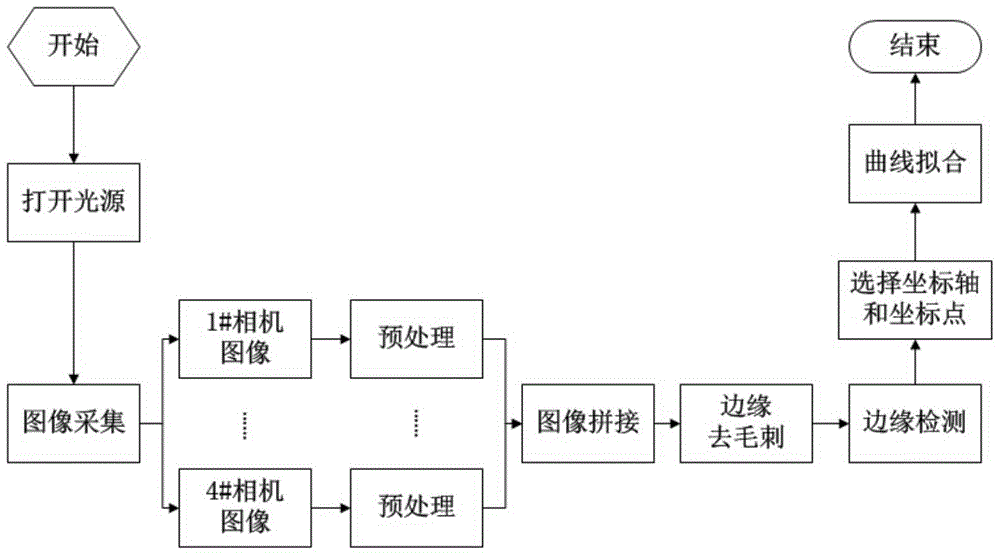

[0040] like figure 1As shown, the ultra-large shearing machine plate shearing edge curve image detection system of the present invention includes an optical imaging unit, a light source control unit, an image acquisition unit, an image acquisition processing unit and a data processing unit, wherein the light source control unit, the image The processing unit and the data processing unit are integrated in the automation platform 4 . The optical imaging unit includes four industrial cameras and four bar light sources. The industrial cameras include a CCD sensor and a wide-angle lens installed on the CCD sensor. The four industrial cameras are arranged in a line array and are located on the sheet metal cutting production line above, and enable the shooting range of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com