Calibration method and calibration system for reference axis deviation of compound detection system

A composite detection and calibration method technology, applied in the direction of measuring devices, instruments, etc., to achieve the effects of high calibration accuracy, strong engineering realization, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The following is a description of the calibration method of the reference axis deviation of the compound detection system based on the specific experimental data:

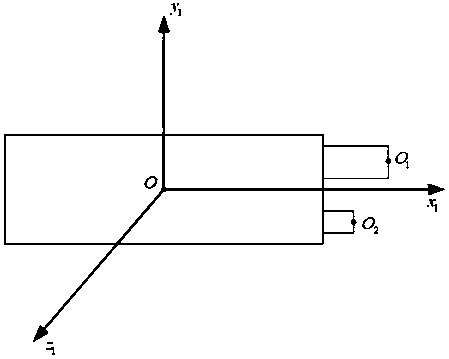

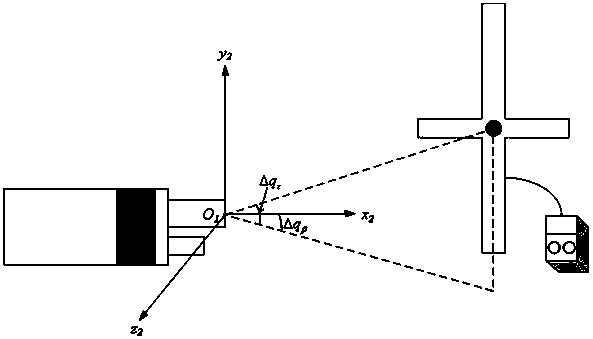

[0058] (1) Take the missile body coordinate system of the weapon system as the reference coordinate system, take the center of mass of the weapon system as the origin O of the reference coordinate system, and take the longitudinal axis of the weapon system as Ox 1 The axis pointing to the head is positive, and the vertical direction in the longitudinal symmetry plane of the weapon system is Oy 1 Axis, pointing up is positive, perpendicular to Ox 1 the y 1 Plane is Oz 1 Axis, the direction is determined according to the right-handed Cartesian coordinate system, O 1 is the imager axis, O 2 is the axis of the laser range finder;

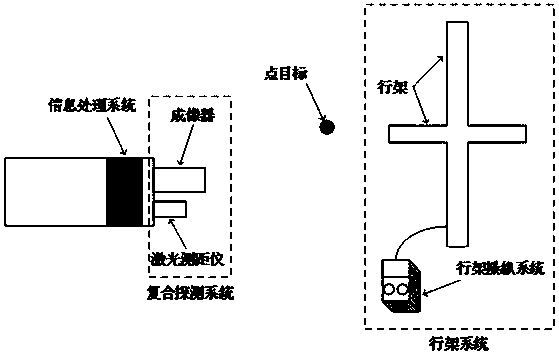

[0059] (2) Fix the point target simulating the non-cooperative target on the traveling frame, and move the traveling frame into the field of view of the imager by controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com