Marine experimental method of steel reinforcement cage built-in concrete

A test method and technology of concrete specimens, which are applied in the field of marine environmental tests and the durability of reinforced concrete, can solve the problems of less built-in metal materials, and the difficulty of fully expressing the durability of reinforced concrete structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0021] Location selection: Zharuoshan Science and Technology Island, Zhejiang University, Zhoushan City, Zhejiang Province, marine engineering materials and full-scale component marine environment test site. The test location in the ocean tidal zone should have the ability to act on seawater tides, that is, to ensure that the concrete specimens are exposed to seawater for a period of 8 hours to 16 hours a day.

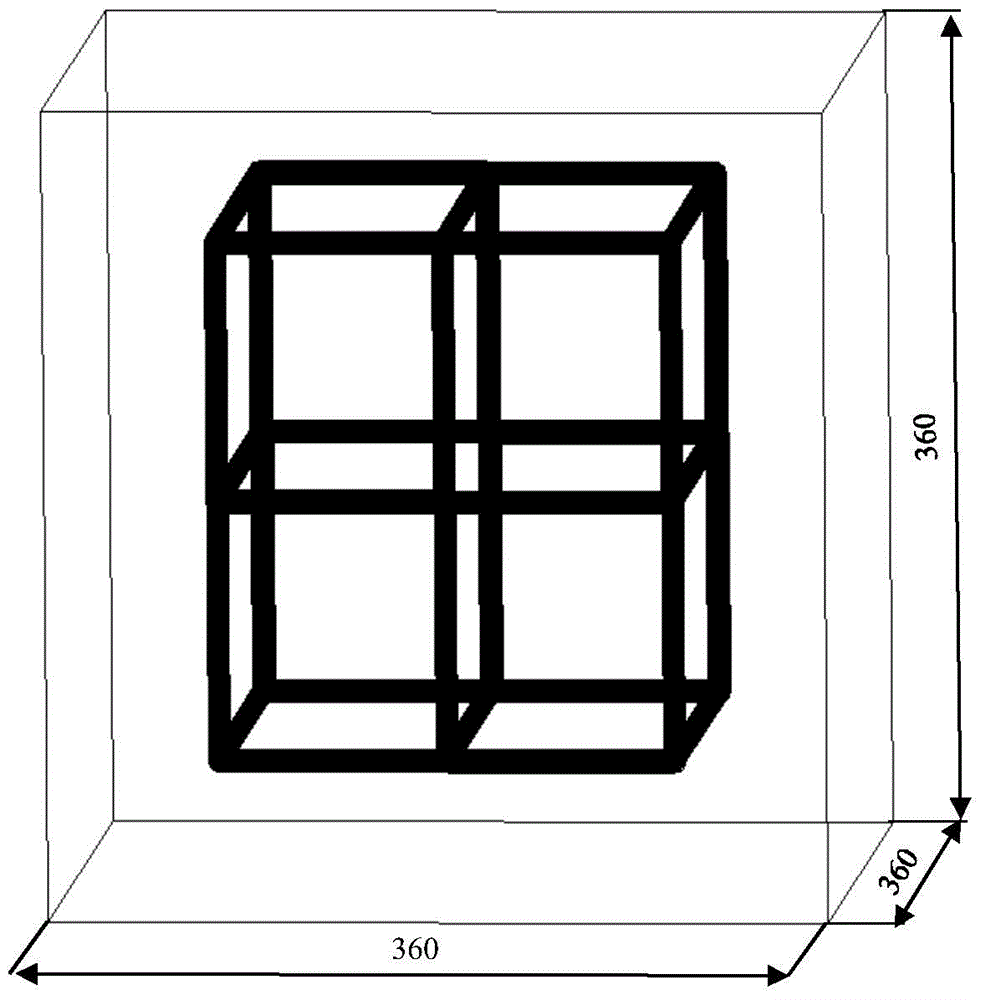

[0022] Manufacture of specimen 1: choose C40 grade concrete, specimen size: 360mm×360mm×360mm.

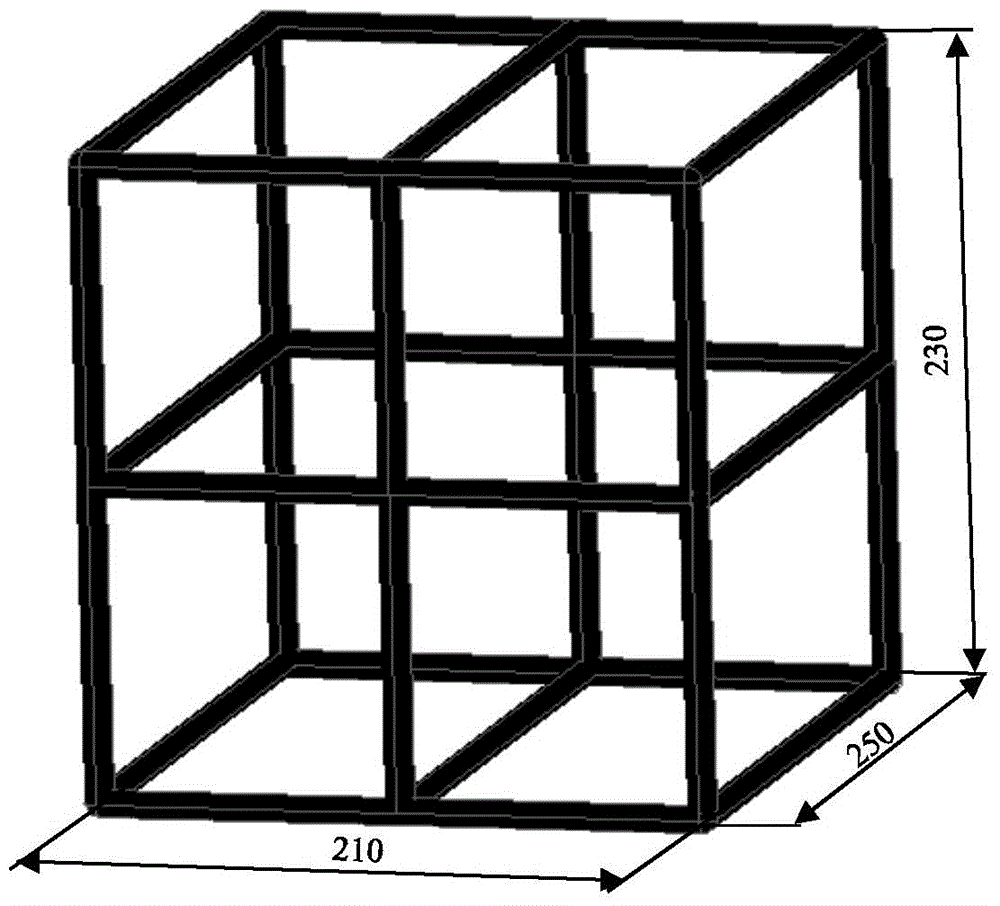

[0023] Built-in reinforcement cage: a built-in six-sided reinforcement cage with a side length of 210mm×230mm×250mm, its structure is shown in the figure, and the thickness of the control protective layer is 75mm, 65mm and 55mm.

[0024] Manufacture of specimen 2: choose C50 grade concrete, specimen size: 300mm×300mm×5000mm.

[0025] Built-in reinforcement cage: a built-in six-sided reinforcement cage with a side length of 210mm×230mm×420mm, its structure is shown in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com