Printed circuit board (PCB) combining and joining method and system

A technology of PCB boards and sub-boards, which is applied in the field of PCB board combination method and combination system, which can solve the problems of over-reliance on employee experience, high manual operation error rate, and low combination efficiency, so as to reduce the dependence on employee experience , Reduce online production batches, and ensure the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below:

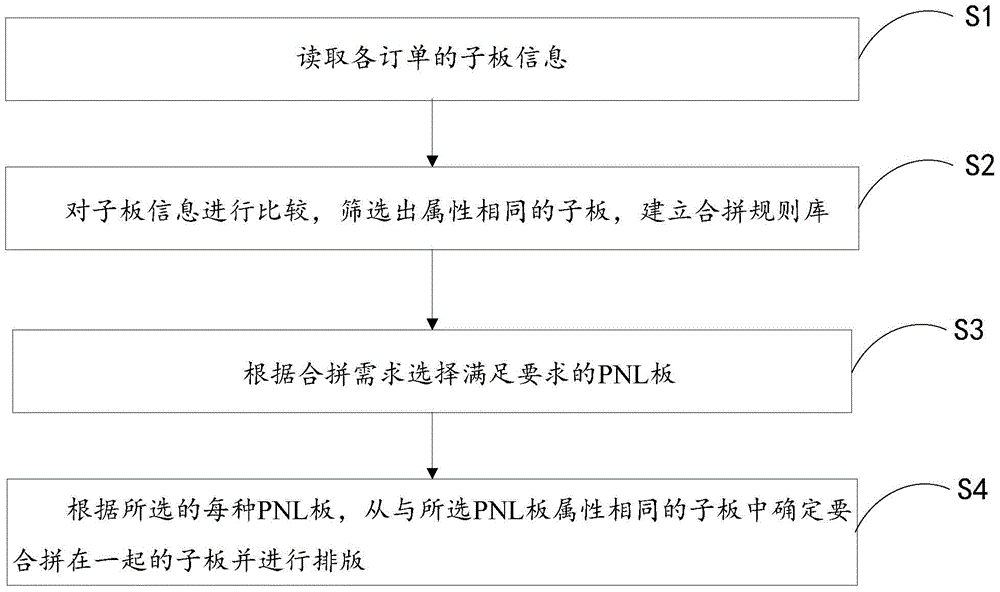

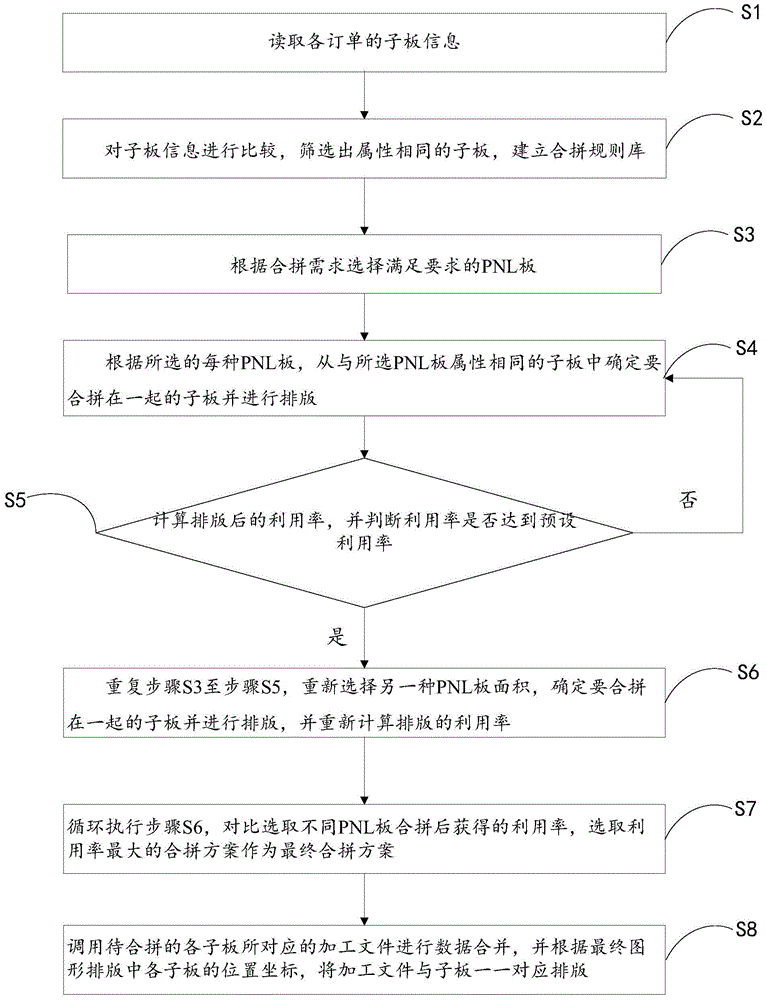

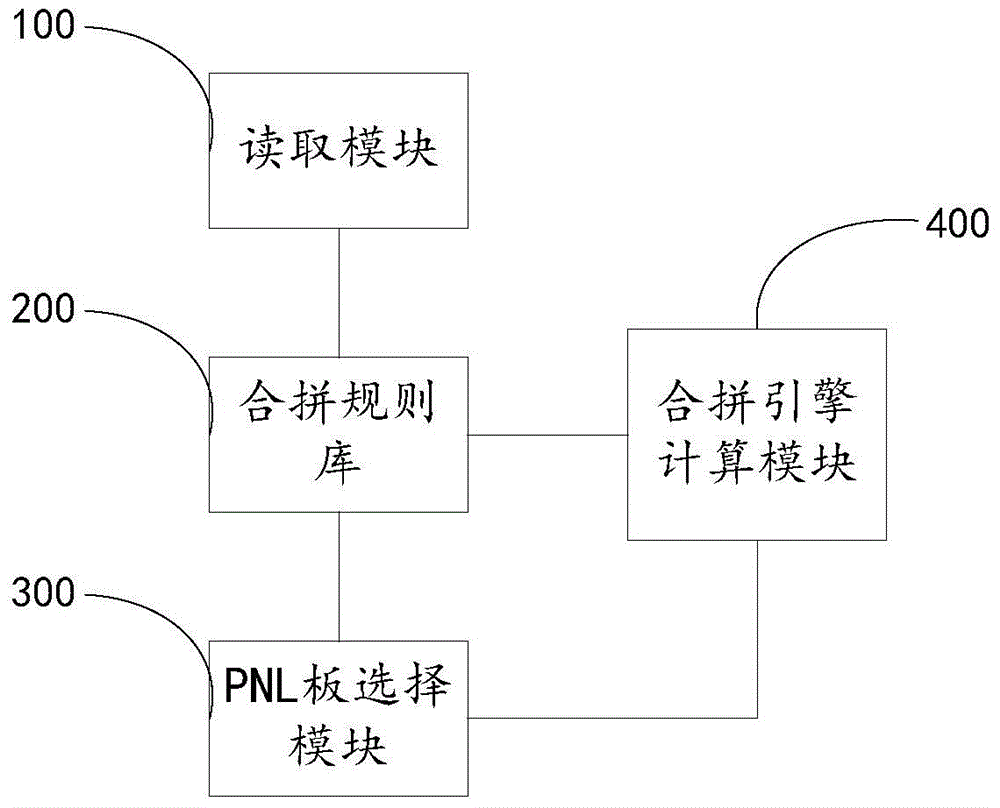

[0022] like figure 1 Shown, a kind of PCB board combination method comprises the following steps:

[0023] S1. Read the sub-board information of each order. The sub-board information includes the area, delivery quantity and attributes of each sub-board. The attributes include at least the order delivery date, order type, number of sub-board layers, board thickness, and board material. , surface technology, inner layer copper foil thickness, outer layer copper foil thickness, solder mask color and character color, etc.;

[0024] S2. Comparing the sub-board information, screening out the sub-boards with the same attributes, and establishing a combination rule base;

[0025] S3. Select PNL boards that meet the requirements according to the merger requirements;

[0026] S4. According to each selected PNL board, determine the sub-boards to be merged together from the sub-boards with the same attributes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com