Lead-free perovskite film, and preparation method and application thereof

A lead-free perovskite and thin film technology, which is applied in the field of solar cells, can solve the problems of unfavorable industrialization development and low coverage of perovskite thin films, and achieve the effects of facilitating large-scale production, environmental protection, and smooth thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

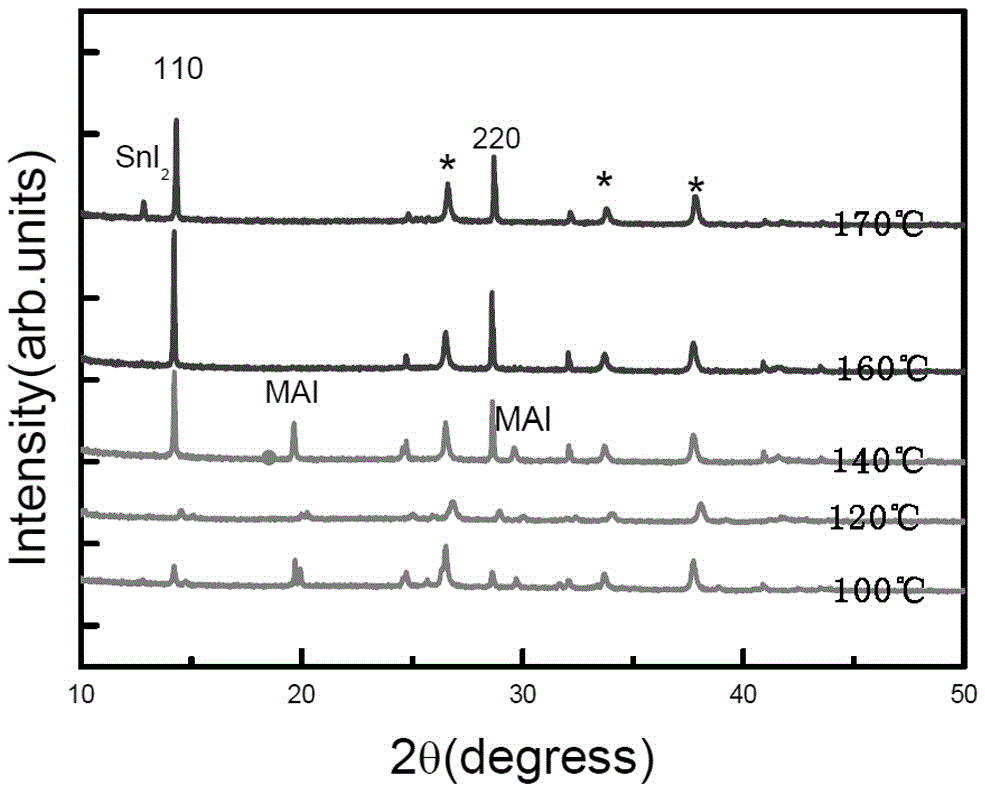

[0027] The general chemical formula of the lead-free perovskite film provided by the present invention is CH 3 NH 3 wxya 3 ; Wherein, X is Cl, Br or I. The preparation method of the lead-free perovskite film is as follows:

[0028] a. Weigh SnX 2 Powder and CH 3 NH 3 X powder, X is Cl, Br or I.

[0029] b. The weighed SnX 2 and CH 3 NH 3 X is placed in the chamber of the co-evaporation equipment as two evaporation sources, and the substrate (or substrate, base) is placed in the chamber of the co-evaporation equipment at the same time; the co-evaporation equipment can be a multi-source co-evaporation equipment.

[0030] c. Vacuum the chamber of the co-evaporation equipment; generally, it can be vacuumed to 5×10 -5 Pa~30×10 -5 Pa.

[0031] d. First, the evaporation source SnX 2 is heated so that the SnX 2 Evaporated and deposited on the substrate; then stop the evaporation source SnX 2 heating, and then the evaporation source CH 3 NH 3 X is heated so that CH 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com