Radio frequency connector and manufacturing method thereof

A radio frequency connector and radio frequency technology, applied in the field of signal transmission, can solve the problems of inaccurate positioning, complicated process, low welding temperature, etc., and achieve the effect of ensuring air tightness and radio frequency performance, simple process and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

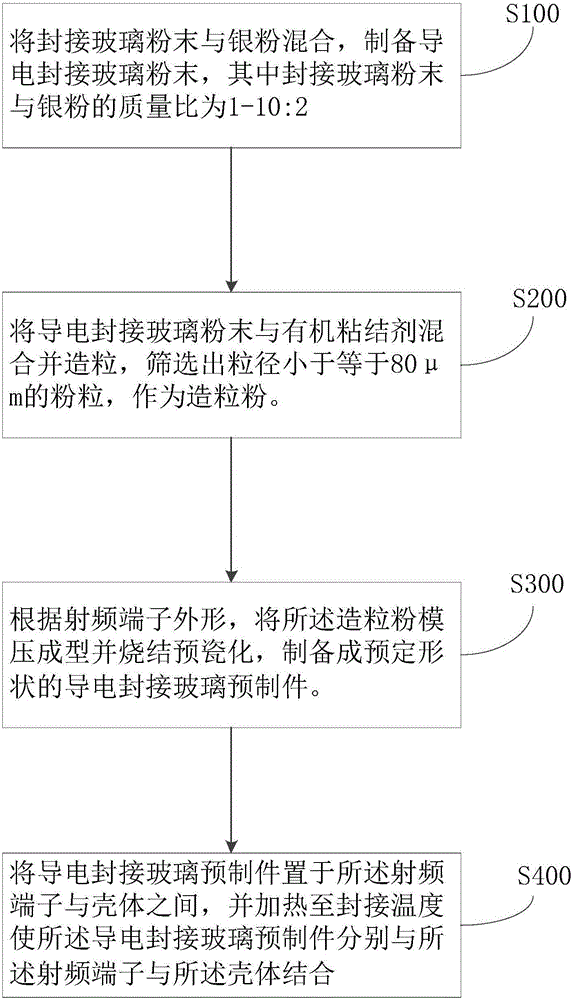

[0029] Embodiment 1 of the present invention provides a method for preparing a radio frequency connector, such as figure 1 As shown, it includes the following steps:

[0030] Step S100: Mix sealing glass powder and silver powder to prepare conductive sealing glass powder, wherein the mass ratio of sealing glass powder to silver powder is 0.5-10:1.

[0031] Step S200: Mix and granulate the conductive sealing glass powder and the organic binder, and screen out the powder particles with a particle size smaller than or equal to 80 μm as the granulated powder.

[0032] Step S300: According to the shape of the radio frequency terminal, the granulated powder is molded and sintered to pre-ceramize, so as to prepare a conductive sealing glass prefabricated part of a predetermined shape.

[0033] Step S400: Place the conductive sealing glass preform between the radio frequency terminal and the housing, and heat it to the sealing temperature, so that the conductive sealing glass preform...

example 1

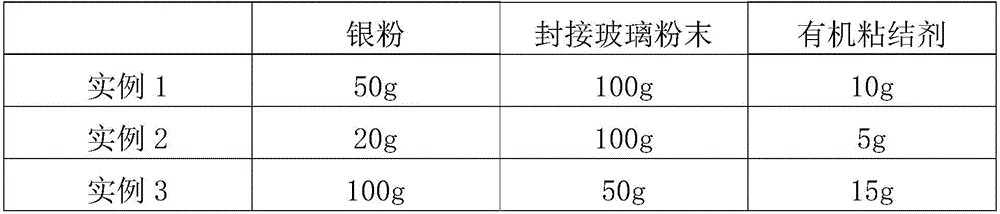

[0041] (1) First, 100 g of PbO-ZnO-B with an average particle size of 20 μm or less 2 o 3 Seal the glass powder and fully and evenly mix it with 50g of flaky silver powder with an average particle size of 3 μm or less. The PbO-ZnO-B used in it 2 o 3 The practical sealing temperature of the sealing glass powder is 450°C, and the composition is PbO: 35%; ZnO: 26%; B 2 o 3 : 35%; other impurities: 4%.

[0042] (2) Add 10 g of polyvinyl alcohol to the mixture obtained in the previous step, heat and stir, granulate and sieve to obtain granulated powder with a particle size below 35 μm.

[0043] (3) Use the above-mentioned granulated powder to press into a conductive sealing glass preform body, which is ring-shaped, with an outer diameter of 2.9 mm, an inner diameter of 2.8 mm, and a thickness of 2.0 mm.

[0044](4) Debinding the above-mentioned sealing glass body at 200-350° C., and pre-ceramicizing at 300-350° C. to obtain a conductive sealing glass preform. The pre-ceramiz...

example 2

[0047] (1) First, 100g of PbO-ZnO-B 2 o 3 The sealing glass powder is fully and evenly mixed with 20g of flake silver powder with an average particle size of 3 μm or less, and the sealing temperature of the sealing glass powder used is 350°C.

[0048] (2) Add 5 g of polyvinyl alcohol to the mixture obtained in the previous step, heat and stir, granulate and sieve to obtain granulated powder with a particle size below 40 μm.

[0049] (3) Use the above granulated powder to press into a ring green body, deglue at 200-250° C., and pre-ceramize at 250-300° C. to obtain a conductive sealing glass preform. The pre-ceramized conductive sealing glass preform has an outer diameter of 2.3 mm, an inner diameter of 2.0 mm, and a thickness of 2.0 mm.

[0050] (4) Assemble the above-mentioned conductive sealing glass prefabricated part with a radio frequency terminal with an outer diameter of 2.0 mm, and a connector housing, and keep warm at 380 degrees Celsius for 20 minutes to obtain a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com