An integrated high temperature resistant electromagnetic induction coil

An electromagnetic induction coil, high temperature resistant technology, applied in the direction of induction heating, coil devices, etc., can solve the problems of coil inductance stability and life-span adverse effects, inductance linearity space position drift, etc., to improve impact resistance and tensile strength , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

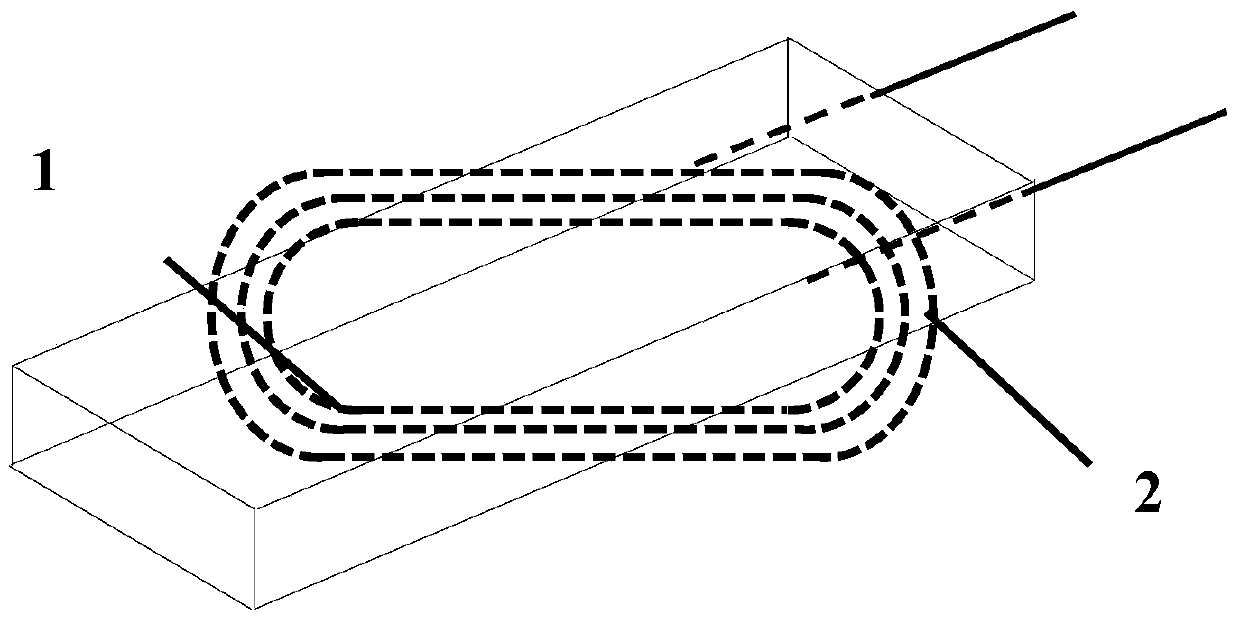

[0012] Embodiment 1, the nickel wire of outsourcing inorganic high-temperature-resistant insulating skin is coiled into the shape of electromagnetic induction coil 1 and pressed into the electrical insulation amorphous refractory castable or ceramic powder stirred with solvent, and the terminal of the coil is kept outside. Pound to drive out the air bubbles in the amorphous refractory castable or ceramic powder, so that the electromagnetic induction coil 1 is closely combined with the amorphous refractory castable or ceramic powder. After the amorphous refractory castable is completely solidified or the ceramic powder is sintered, the internal An electrically insulating refractory material entity 2 including an electromagnetic induction coil 1, this structure can be used for inductive deviation correction in a high temperature environment (500-1200°C).

Embodiment 2

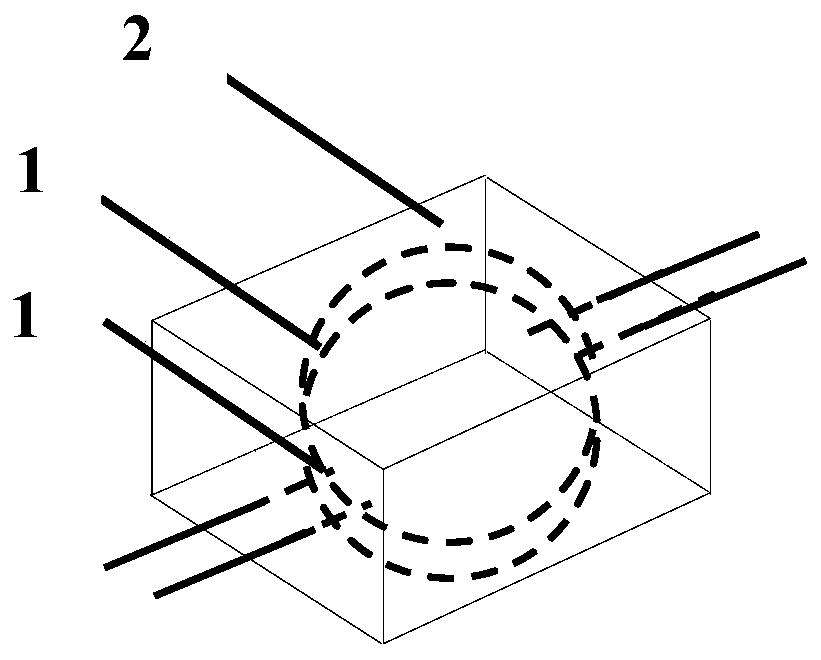

[0013] Embodiment 2, the nickel wire of the outsourcing inorganic high-temperature-resistant insulating skin is coiled into two electromagnetic induction coils 1 arranged up and down, and pressed into the electrically insulating amorphous refractory castable or ceramic powder stirred with the solvent, and the terminals of the coils are kept Externally, by vibrating, the air bubbles in the unshaped refractory castable or ceramic powder are driven out, so that the electromagnetic induction coil 1 is closely combined with the unshaped refractory castable or ceramic powder, and after the unshaped refractory castable is completely solidified or the ceramic powder is sintered , the electrical insulating refractory material entity 2 that contains two electromagnetic induction coils 1 can be obtained. One of the two internal electromagnetic induction coils 1 can be used as a transmitting coil, and the other can be used as a receiving coil. This internally contains two electromagnetic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com