Threshing cylinder tooth component of whole-feed harvesting machine

A threshing drum and full-feeding technology, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of fragility, entanglement of grass, and reduction of grain breakage rate, and achieve high overall strength, low production cost, and prevent The effect of interstitial grass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

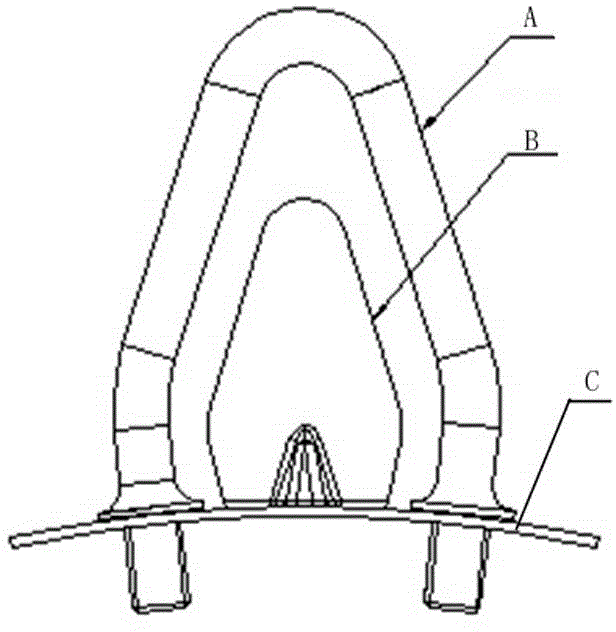

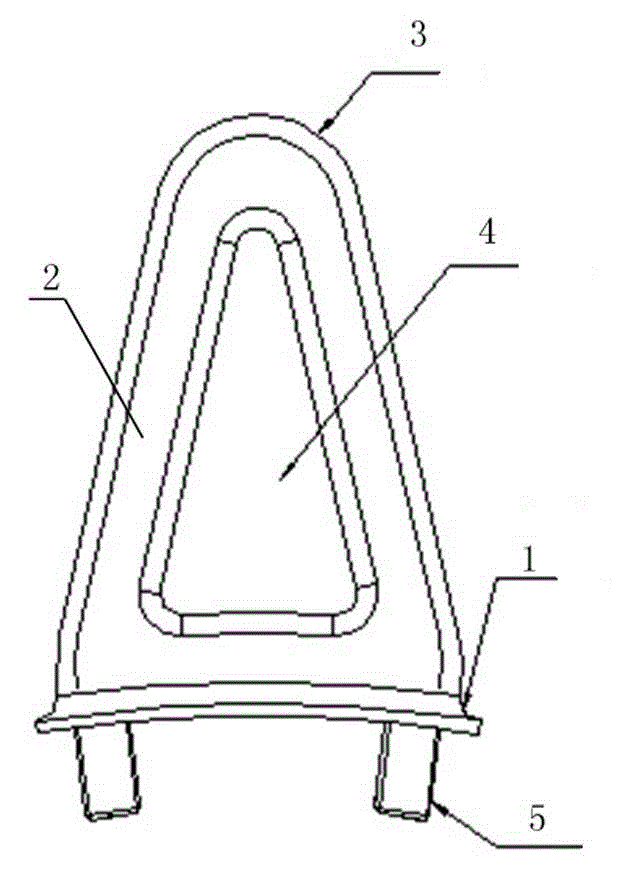

[0014] The present invention as image 3 shown.

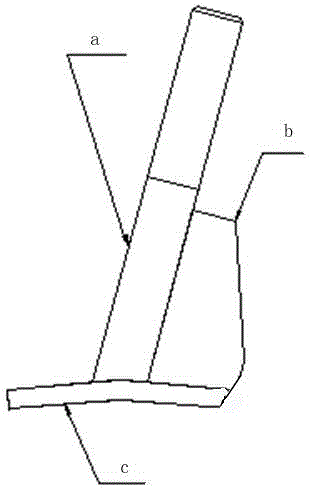

[0015] A full-feed combine harvester threshing drum tooth component, including a mounting base 1, on which is provided a drum tooth 2, the drum tooth 2 is forged from 45# material, the drum tooth 2 and the anti-winding piece 4 inside it As a whole, there is no gap between the anti-winding sheet 4 and the roller teeth 2.

[0016] The middle part of the roller tooth 2 is conical, the top end 3 of the protrusion is arc-shaped, and the two sides are symmetrical in shape.

[0017] When specifically manufactured:

[0018] The top of the roller tooth 2 is a circular arc transition, the middle part of the tooth is conical, the bottom of the roller tooth 2 has a mounting base 1 and a mounting bolt 5, and the central part of the roller tooth 2 is a forged anti-winding piece 4.

[0019] The roller tooth 2 is made of 45# material as a whole by forging process, and then the surface hardness reaches HRc57~63 after heat treatment process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com