Front-end refrigerating and regenerated gas recycling and heating system for adsorbing drying machine

An adsorption dryer and regeneration gas technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of large noise, poor quality of unrefrigerated gas to be compressed, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

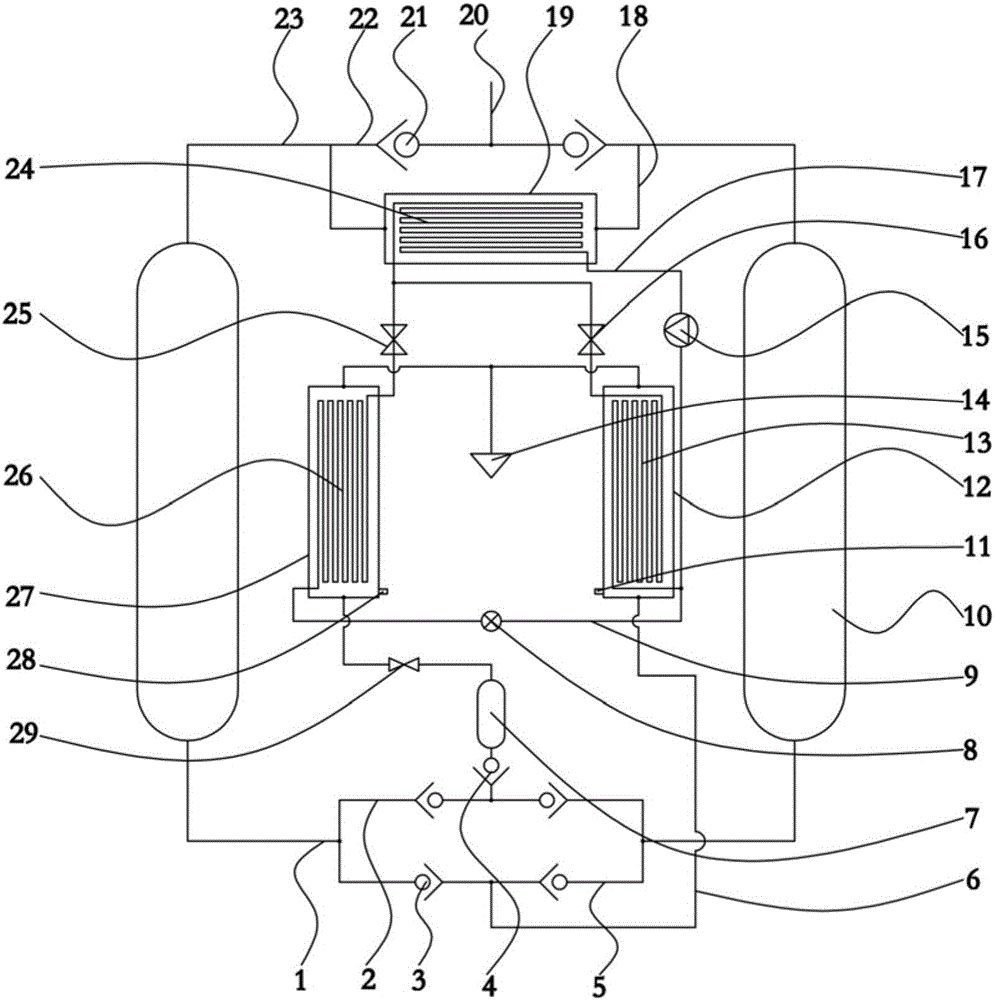

[0035]This embodiment discloses a front-end refrigeration and regeneration gas recovery and heating system of an adsorption dryer, which is used to recover the regeneration gas after regeneration of the dryer, and heat a part of the product gas used for regeneration after adsorption drying , and refrigerating the input compressed gas and recovered regeneration gas, including the lower air channel 1, opposite to the intake chamber 5 and exhaust chamber 2 arranged on the lower air channel 1, for recovering the recovery gas of the regeneration gas Road 6, a refrigerant circulation module for dehumidification, refrigeration and heating, an electric control component 31 for electrical control, and an air control component 32 for pneumatic control, which are arranged on the lower air channel 1 for adsorption or regeneration cylinder body 10, an upper air passage 23 communicated with the cylinder body 10, an air outlet chamber 22 arranged on the upper air passage 23, an air outlet pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com