Cyclone gasification furnace

A gasification furnace and cyclone technology, applied in the field of gasification furnaces, can solve the problems of low comprehensive utilization rate and gasification efficiency, prolonged reaction time, low gas quality, etc., to reduce the outer surface area of the furnace body, reduce heat loss, and reduce manufacturing The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

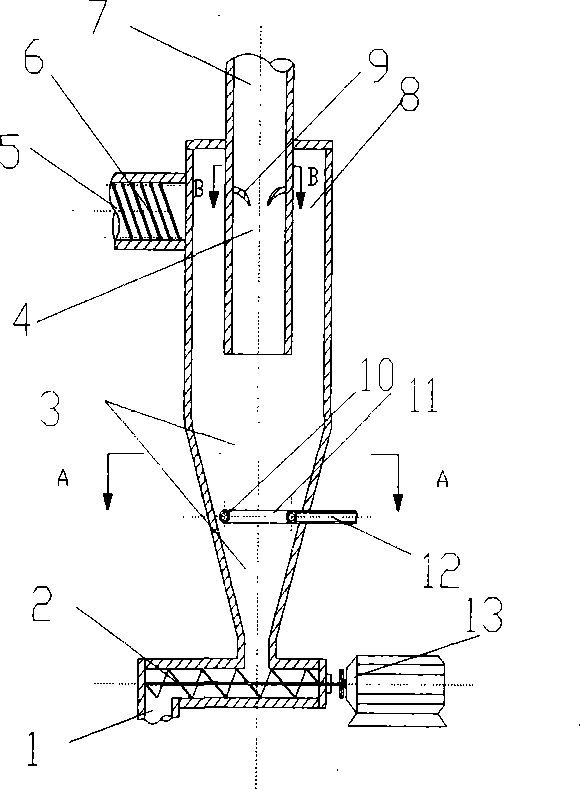

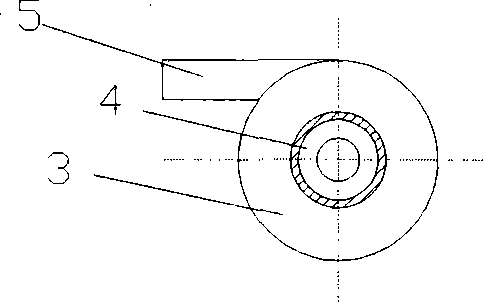

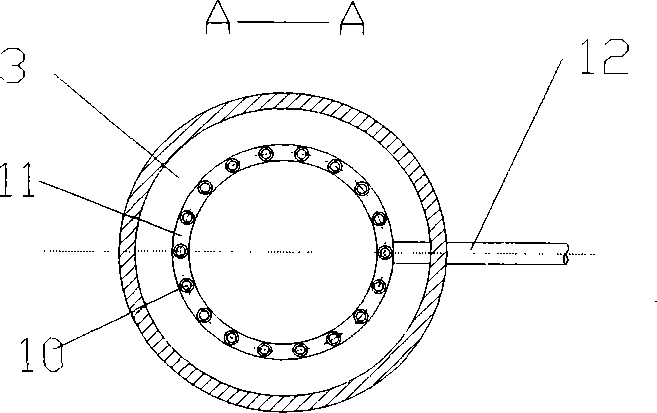

[0014] Depend on figure 1 , figure 2 , image 3 , Figure 4 As shown, the upper part of the furnace body is cylindrical, and a cylindrical combustion gasification chamber (8) and a cylindrical gasification chamber (4) are arranged, and the cylindrical combustion gasification chamber (8) and the cylindrical gasification chamber (4) are the same Shaft arrangement, the fuel inlet (5) is arranged on the upper part of the cylindrical combustion gasification chamber (8) and arranged tangent to it, the resistance wire igniter (6) is arranged in the fuel inlet (5), and the upper part of the cylindrical gasification chamber (4) A gray baffle (9) is set, and a flue gas outlet (7) is set on the top; the lower part of the furnace body is a conical gasification chamber (3) which is the same as the cylindrical combustion gasification chamber (8) and the cylindrical gasification chamber (4). Shaft arrangement, a water vapor inlet (12) is set in the middle of the conical gasification cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com