A three-axis Cartesian coordinate large-capacity dispensing machine

A technology of Cartesian coordinates and dispensing machines, applied in the field of automation, to achieve the effects of improving work efficiency, stable and reliable glue pushing process, and improving glue pushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

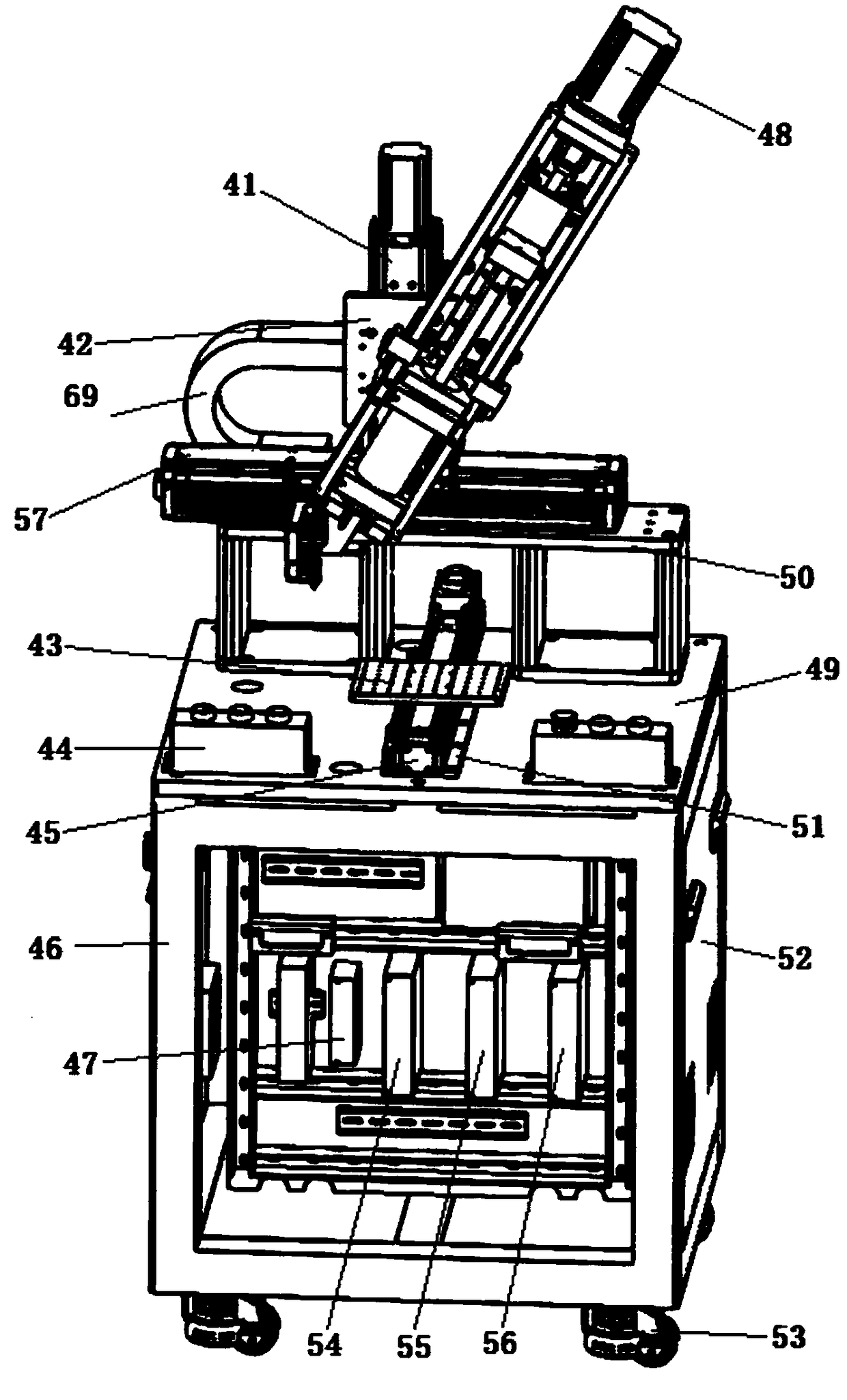

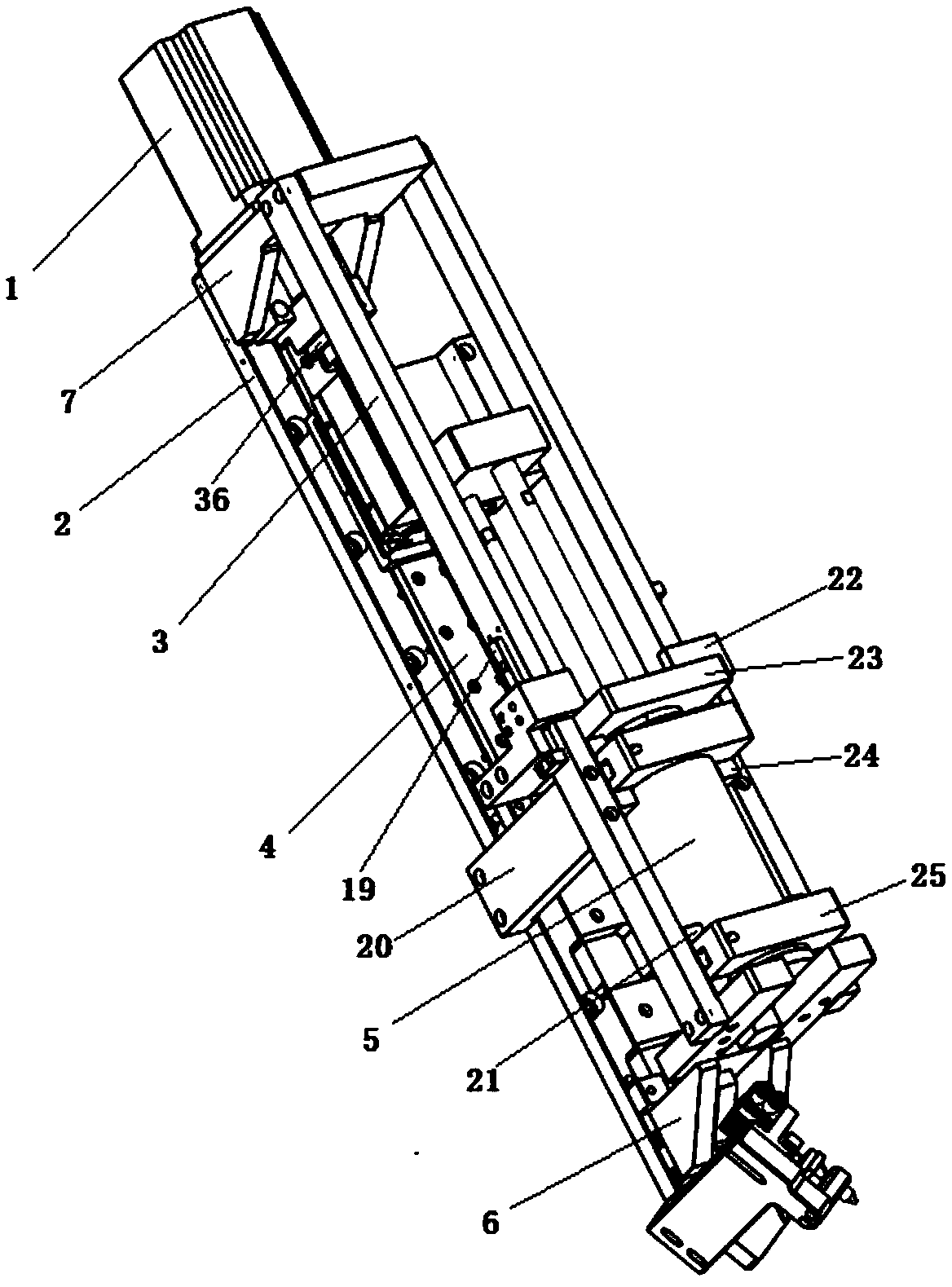

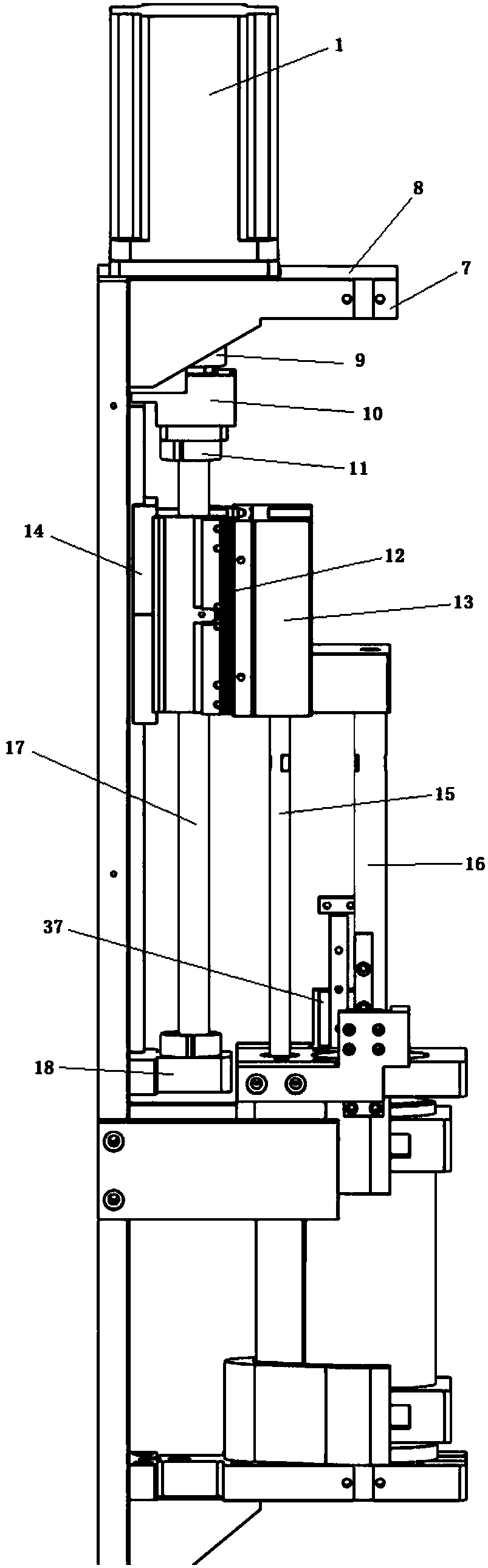

[0031] Such as Figure 1-5 As shown, a three-axis Cartesian coordinate dispensing machine is disclosed in this embodiment, including a dispensing machine frame, a Cartesian coordinate control system, and a stepping glue pushing mechanism 48;

[0032]The frame includes an outer frame 46, a base plate 49, an electrical control unit, a side door panel 52, and a roller support foot 53. The base plate 49 is horizontally fixed on the outer frame 46, and an electrical control unit is arranged inside the outer frame 46. The electrical control unit includes an X-axis servo drive 54. Y-axis servo driver 55, Z-axis servo driver 56, stepper motor driver 47, side door panels 52 are arranged around the outer frame 46, and four corners below the outer frame 46 are provided with roller support feet 53 for level adjustment;

[0033] Cartesian coordinate control system comprises Z-axis 42, Y-axis 45, Z-axis 41, is provided with test substrate 51 on the axis of substrate 49, Y-axis 45 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com