Highly effective low-temperature vaporized refrigeration and heat supply system

A low-temperature evaporation and heating system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high precision requirements for manufacturing equipment, harsh manufacturing conditions, and many manufacturing processes, and meet the precision requirements of manufacturing equipment low cost, simple manufacturing equipment, and low manufacturing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

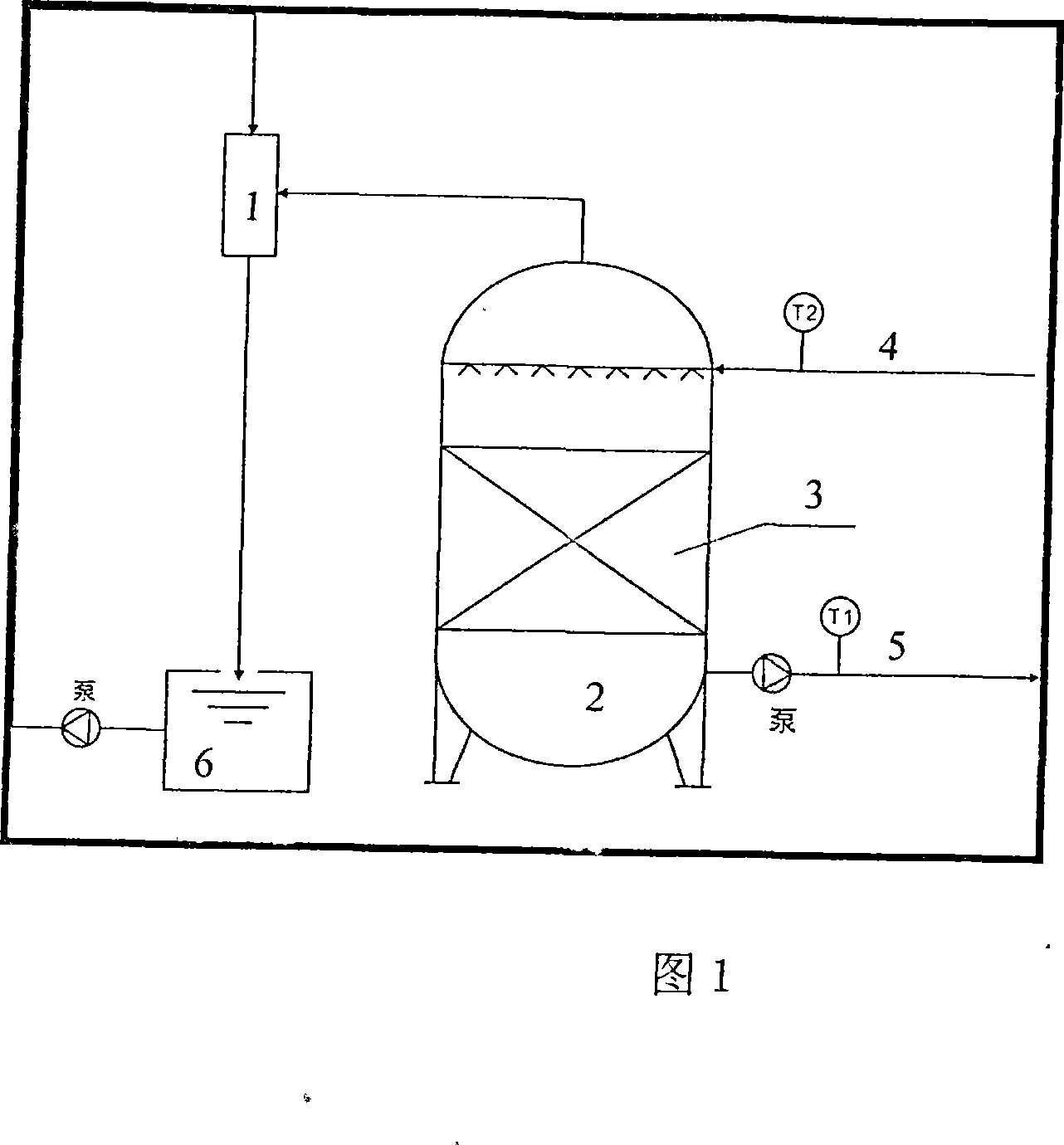

[0008] With reference to accompanying drawing 1, its structure is that the refrigerant water vapor of high-efficiency low-temperature evaporative cooler 2 is connected with the vacuum tube of jet vacuum device 1 through its output pipe, enters the water collecting tank 6, and the water temperature of collecting water tank is improved; The water circulation output pipe of the hot water tank is connected with the water inlet pipe of the jet vacuum device through a high-pressure water pump, so that the jet vacuum device generates a vacuum; There is a water pump and a thermometer T1 showing the water temperature; the upper part of the high-efficiency low-temperature evaporative cooler 2 is provided with a refrigerant water return pipe 4, and a thermometer T2 is provided on the refrigerant water return pipe 4 to display the return water temperature; The inside of the body of the evaporative cooler is equipped with a spraying device and packing, wherein the spraying device is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com